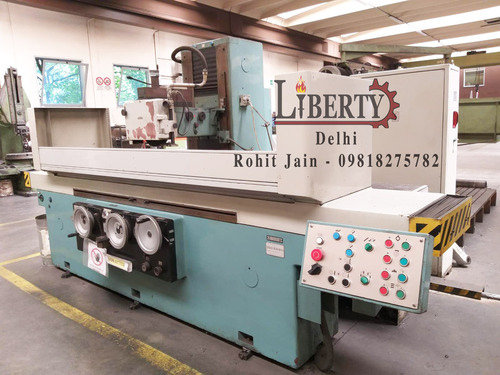

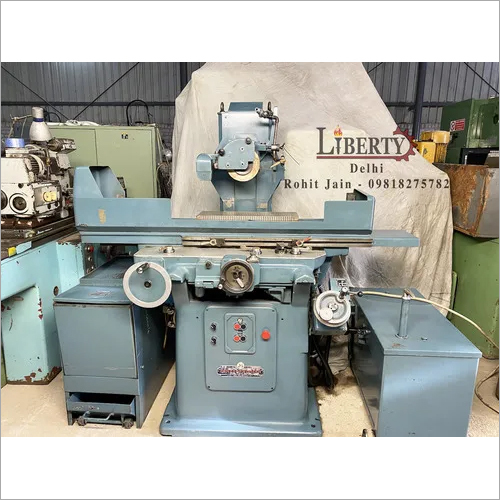

Alpa 500 x 700 Surface Grinding Machine

Price 15000 INR/ Piece

Alpa 500 x 700 Surface Grinding Machine Specification

- Rotation

- Horizontal

- Model

- Alpa 500 x 700

- Product Type

- Surface Grinding Machine

- General Use

- Industrial Surface Grinding

- Material

- Cast Iron

- Type

- Surface Grinder

- Capacity

- Heavy Duty

- Weight (kg)

- Approx. 3200 kg

- Computerized

- No

- Automatic

- No

- CNC Or Not

- Not CNC

- Control System

- Manual

- Table Size

- 500 x 700 mm

- Table Slide Way

- V & Flat

- Magnetic Chuck Size

- 500 x 700 mm

- Grinding Wheel Size

- 355 x 38 mm

- Grinding Wheel Speed

- 1450 RPM

- Grinding Length

- 700 mm

- Floor Space

- 2100 x 1600 mm

- Fuel Tank Capacity

- Approx. 50 L

- Spindle Speed

- 1450 RPM

- Power

- 5 HP

- Voltage

- 380-440 V

- Dimension (L*W*H)

- 2100 x 1600 x 1700 mm

- Feature

- High Precision

- Color

- Green / White

- Safety Features

- Overload Protection

- Lubrication System

- Automatic

- Table Traverse Motor

- 1 HP

- Coolant System

- Included

- Max Distance from Table to Spindle Centre

- 375 mm

- Hydraulic System

- Standard

- Spindle Bearings

- Antifriction Bearings

- Wheel Head Motor

- 5 HP

- Max Grinding Height

- 375 mm

- Machine Construction

- Robust Meehanite Casting

- Working Speed

- Variable

- Finishing

- Heat Treated Precision Ground

- Cross Feed Motor

- 0.5 HP

- Longitudinal Table Travel

- 725 mm

- Work Table Load Capacity

- Up to 800 kg

- Noise Level

- Low

About Alpa 500 x 700 Surface Grinding Machine

Make - Alpa (Italy)

Model - RTL 700

Job Grinding Size - 500 mm x 700 mm

Max. Longitudinal Travel - 800 mm

Max. Cross Travel of Table - 540 mm

Current Magnet Size - 350 mm x 600 mm

Grinding Wheel Size - Diameter 400 mm x 50 mm Width

Max. Distance b/w Magnet Top to Wheel-Axis - 420 mm

- Equipped with a Wheel-top mounted Hydraulic Wheel Dresser.

- Motorized Rapid Vertical Travel of the Wheel Head.

- Automatic Depth Adjustment "Auto-Cut"

- Complete with Coolant Tank & Pump.

- Machine is in excellent working condition.

Video link - https://youtu.be/AbxHJBskCb8

Robust Construction and Heavy-Duty Performance

Featuring a solid Meehanite cast iron body, the Alpa 500 x 700 Surface Grinding Machine is designed to endure rigorous industrial workloads. Its table accommodates up to 800 kg, offering stability and reducing vibration during operations. With heat-treated and precision-ground finishing, it delivers smooth, accurate results ideal for heavy-duty grinding applications.

Precision Engineering and Versatile Operation

Designed for high precision, this surface grinder integrates antifriction spindle bearings and an automatic lubrication system for consistent, smooth performance. Variable speeds and manual controls allow operators to handle different materials and components, while the included coolant and hydraulic systems enable long operational life.

Enhanced Safety and Easy Maintenance

Equipped with overload protection, automatic lubrication, and a low-noise profile, the Alpa 500 x 700 prioritizes operator safety and comfort. Maintenance is straightforward, thanks to durable components and accessible design. Its robust systems offer lasting reliability, making it a sound investment for busy industrial workshops.

FAQs of Alpa 500 x 700 Surface Grinding Machine:

Q: How is the Alpa 500 x 700 Surface Grinding Machine typically used in industrial environments?

A: This machine is primarily used for high-precision surface grinding of large metal components. Its heavy-duty table and robust construction allow it to handle substantial workpieces, making it well-suited for manufacturing, engineering, and tooling workshops demanding exact surface finish and dimensional accuracy.Q: What are the main benefits of the automatic lubrication and coolant systems?

A: The automatic lubrication system ensures essential moving parts remain properly lubricated, reducing wear and maintenance needs. The included coolant system keeps the workpiece and grinding wheel at optimal temperatures, preventing overheating and helping to achieve high-quality, consistent finishes.Q: Where can this surface grinder be installed given its size and power requirements?

A: With dimensions of 2100 x 1600 x 1700 mm and operating voltages between 380-440 V, the Alpa 500 x 700 is best suited for industrial spaces with sufficient floor area and high-capacity electrical supply. Factories, workshops, and manufacturing plants are ideal installation locations.Q: What is the process for adjusting the working speed and table movements?

A: The machine features manual controls that allow operators to adjust the working speed and table movements according to material requirements and workload. The variable speed ensures optimal grinding precision, while hydraulic systems support smooth, controlled table traverse.Q: When should maintenance be performed on this surface grinder?

A: Routine maintenance should be carried out as recommended in the user manual, including checking lubrication levels, inspecting spindle bearings, and monitoring the coolant system. With automatic lubrication and robust components, the machine minimizes frequent maintenance, enhancing operational uptime.Q: How does the machines robust casting and precision ground finishing benefit users?

A: Its Meehanite cast iron construction provides exceptional rigidity and stability, reducing vibrations that compromise surface quality. The precision ground finishing ensures both durability and superior accuracy, extending the machines service life and improving overall productivity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Surface Grinder Category

Jakobsen 350 mm x 600 mm Surface Grinder

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : Other, Conventional/Manual controls

Computerized : No

CNC Or Not : Other, Manual

Automatic : Other, Semiautomatic

Jones & Shipman 540 Hydraulic Surface Grinder Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : Other, Hydraulic

Computerized : No

CNC Or Not : Other, Not CNC

Automatic : Other, Semi Automatic

TOS 400 mm x 1500 mm Surface Grinding Machine

Price 1300 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Control System : Manual

Computerized : No

CNC Or Not : Other, No

Automatic : No

Jones & Shipman Surface Grinder Machine

Price 3750 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Control System : Manual

Computerized : No

CNC Or Not : Not CNC, Other

Automatic : No

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry