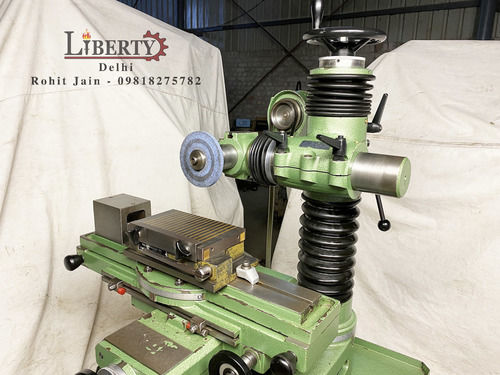

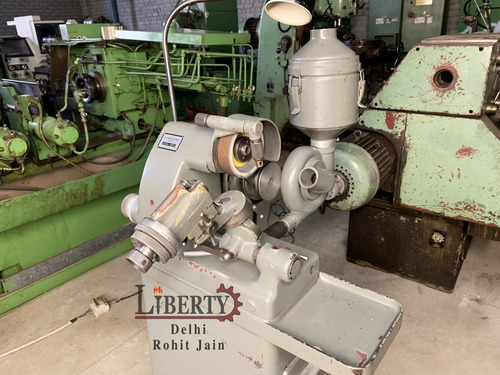

Cerfer Italy Automatic Tool and Cutter Grinder

Price 100000.0 INR/ Piece

Cerfer Italy Automatic Tool and Cutter Grinder Specification

- Cutting Speed

- Variable, up to 20 m/min

- Tool Type

- Milling cutters, drills, reamers, and various cutting tools

- Shape

- Rectangular with precision-ground surfaces

- Machine Type

- Automatic tool and cutter grinder

- Hardness

- Up to 62 HRC

- Cutting Capacity

- Tool diameter up to 200 mm

- Operate Method

- Automatic

- Brooches Type

- Compatible with standard broaches

- Cutter Type

- End mill, side and face, form cutter

- Drill Bits Types

- Straight and taper shank

- Length

- Adjustable for tool length up to 300 mm

- Cutting Accuracy

- ±0.01 mm

- Material

- Heavy-duty cast iron base and high-grade steel components

- Cutting Force

- High, suitable for tough materials

- Operation Type

- Automatic and semi-automatic

- Coating

- Uncoated

- Diameter

- Grinding wheel up to 200 mm

- Processing Type

- Tool and cutter grinding

- Coolant System

- Integrated, recirculating coolant pump

- Grinding Wheel Material

- Aluminum oxide or CBN

- Power Supply

- Three-phase, 380V, 50Hz

- Control System

- Electromechanical automatic controls

- Safety Features

- Emergency stop, overload protection, safety guards

- Spindle Speed

- 2200 RPM

- Blade Size

- Customizable based on application

- Dimensions (L x W x H)

- 1900 x 1200 x 1450 mm

- Net Weight

- Approx. 950 kg

- Wheel Head Tilt Angle

- Vertical and horizontal adjustable

- Work Table Movement

- X/Y/Z axis with micrometric feed

Cerfer Italy Automatic Tool and Cutter Grinder Trade Information

- Minimum Order Quantity

- 1 Piece

- Main Domestic Market

- All India

About Cerfer Italy Automatic Tool and Cutter Grinder

Make - Cerfer (Italy)

Max. Job Diameter over Cross-Slide - 240 mm

Max. Job Diameter over Bed - 340 mm

No. of Flutes - 1 to 12 Flutes

Range of Relief in Longitudinal Travels - 30 mm to -10 mm

Work-Head Rotation - Automatic ; 3 Speeds

- Automatic Longitudinal Relief Grinding Feature.

- Complete with lots of collets, quills & other accessories etc.

- Complete with Coolant Tank and Pump.

- Machine is in excellent working condition.

Video of the Machine -

Advanced Control System

Equipped with electromechanical automatic controls, the Cerfer Italy grinder simplifies complex tool sharpening and improves operational efficiency. Its three-phase power supply ensures a reliable and consistent performance, essential for high-volume, industrial applications requiring repeatable results.

Safety and Precision Engineering

Safety is paramount, featuring emergency stop functions, overload protection, and safety guards. Precision-ground rectangular surfaces and a heavy-duty cast iron base reduce vibration, while the micrometric feed system and variable cutting speeds help achieve an exceptional cutting accuracy of 0.01 mm.

Versatile Grinding Applications

This grinder accommodates a variety of cutting tools, including straight and taper shank drill bits, end mills, side and face cutters, and form cutters. With adjustable tool length capabilities up to 300 mm and the ability to grind tool diameters up to 200 mm, it supports a wide range of industrial grinding needs.

FAQs of Cerfer Italy Automatic Tool and Cutter Grinder:

Q: How does the automatic control system enhance the grinding process?

A: The electromechanical automatic controls streamline the grinding operation by allowing automated adjustments and optimized tool positioning, resulting in improved consistency, accuracy, and reduced operator workload.Q: What is the maximum tool size that can be processed on this grinder?

A: The Cerfer Italy Automatic Tool and Cutter Grinder accommodates tools with diameters up to 200 mm and adjustable lengths up to 300 mm, making it suitable for a wide variety of industrial cutting tools.Q: When should I use the vertical or horizontal wheel head tilt feature?

A: The wheel head tilt feature is used to adapt the grinding wheel position for specific tool geometries. Vertical tilt is ideal for end mills or face cutters, while horizontal tilt is utilized for side cutters or form tools requiring different angles.Q: Where can the coolant system be utilized during grinding?

A: The integrated recirculating coolant pump continually supplies coolant to the grinding zone, reducing heat buildup, extending grinding wheel life, and preserving tool integrity throughout the process.Q: What safety mechanisms are integrated within the machine?

A: The grinder is fitted with emergency stop buttons, overload protection, and robust safety guards to safeguard operators during both automatic and semi-automatic modes.Q: How precise is the grinding operation and what benefit does it offer?

A: The machine achieves a grinding accuracy of 0.01 mm. This level of precision minimizes tool wear, enhances output quality, and ensures tools perform optimally for demanding applications.Q: What types of grinding wheel materials are compatible with this equipment?

A: The machine supports both aluminum oxide and CBN grinding wheel materials, providing flexibility for processing various metals and hard materials depending on application requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Tool & Cutter Grinder Category

CG Standard Universal Tool and Cutter Grinder

Price 18000 INR

Minimum Order Quantity : 1 Piece

Machine Type : Universal Tool & Cutter Grinder

Tool Type : Universal Tool Grinder

Features : Swiveling head, adjustable tailstock, robust cast iron body, precision slides, easy wheel replacement

Material : Others, Alloy Steel & Cast Iron

Deckel Single-Lip Cutter Grinder

Price 1100 USD ($)

Minimum Order Quantity : 1 Piece

Machine Type : Deckel Cutter Grinder

Tool Type : Cutter grinder

Features : Compact design Manual operation mechanism

Material : Highgrade metal construction, Others

M3 Tool and Cutter Grinder

Price 1100 USD ($)

Minimum Order Quantity : 1 Piece

Machine Type : M3 Tool and Cutter Grinder

Tool Type : Tool Grinder

Features : Grinding Sharpening Tools

Material : Others, Metal and Steel Construction

TOS Tool Cutter & Grinder Machine

Machine Type : Tool Cutter Grinder Machine

Tool Type : Grinding Machine

Features : Precision grinding and cutting

Material : Metal

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry