Coventry Gauge England Horizontal Broaching Machine

Price 100000 INR/ Piece

Coventry Gauge England Horizontal Broaching Machine Specification

- Voltage

- 415 V

- Cooling System

- Integrated Coolant System

- Features

- Robust Structure, Easy Tool Change, Precision Machining

- Motor Power

- 5 HP

- Frequency

- 50 Hz

- Machine Type

- Broaching Machine

- Frame Type

- Heavy Duty, Welded Steel

- Production Capacity

- Custom; up to 100 Pieces/Shift

- Noise Level

- < 80 dB(A)

- Accuracy

- 0.02 mm

- Power Rating

- 5 HP / 3.7 kW

- Operating Temperature

- 5C to 40C

- Control System

- Manual & Semi-Automatic

- Drive

- Direct Coupled Electric Motor

- Lubricating System

- Automatic Lubrication

- Model No

- Coventry Gauge Horizontal

- Product Type

- Horizontal Broaching Machine

- Technology

- Mechanical Broaching Technology

- Power Source

- Electric

- Operating Type

- Automatic

- Power

- 5 HP

- Pressure

- Hydraulic, adjustable

- Surface Treatment

- Painted, Anti-corrosion

- Dimension (L*W*H)

- Approx. 2500mm x 600mm x 1400mm

- Weight (kg)

- Approx. 2400 kg

- Color

- Industrial Green

- Usage & Applications

- Keyway Cutting, Spline Cutting, Internal Profile Broaching

- Broach Stroke Length

- Max 1000 mm

- Table Size

- 600mm x 300mm

- Material Compatibility

- Steel, Alloy Steel, Cast Iron

- Usage

- Precision Industrial Broaching

- Operator Panel

- Analog Indicators

- Tool Clamping System

- Hydraulic Chuck

- Oil Tank Capacity

- 50 Litres

- Phase

- Three Phase

- Safety Features

- Emergency Stop, Overload Protection

- Max Broaching Force

- 15 Tons

- Maintenance

- Low, Easy Access Design

- Broach Return Speed

- Up to 800 mm/min

Coventry Gauge England Horizontal Broaching Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Main Domestic Market

- All India

About Coventry Gauge England Horizontal Broaching Machine

Make - Coventry Gauge & Tool (England)

Tonnage Capacity - 3 Tons

Stroke Length - 760 mm

Type - Pull Type ; Hydraulic

Main Motor - 5 HP

- made under License of American Broach & Machine Co, USA.

- Complete with some spare Broaches, Fixtures & other accessories.

- Machine is in excellent working condition.

Video of The Machine -

Precision and Reliability for Industrial Broaching

Built for the most demanding industrial environments, this horizontal broaching machine offers exceptional precision and lasting durability. Its heavy-duty welded steel frame, hydraulic clamping, and analog operator panel make it well-suited for high-accuracy machining tasks such as keyways and splines. Integrated features like automatic lubrication and robust safety systems minimize downtime and enhance user safety, providing reliable performance shift after shift.

Versatile Applications and User-Friendly Operation

Whether you're cutting keyways, splines, or internal profiles, this broaching machine adapts to your requirements with a custom production capacity of up to 100 pieces per shift. Its automatic and manual control systems accommodate diverse operator preferences, while hydraulic pressure is adjustable for different material types. The easy tool-change mechanism and spacious operator access points streamline setup and maintenance, ensuring uninterrupted workflow.

FAQ's of Coventry Gauge England Horizontal Broaching Machine:

Q: How does the Coventry Gauge Horizontal Broaching Machine ensure precision during operation?

A: The machine features a robust structure, adjustable hydraulic pressure, and analog indicator panels. Its automatic lubrication and integrated coolant system help maintain tool accuracy and stability, delivering broaching results within an accuracy of 0.02 mm.Q: What materials can be processed using this horizontal broaching machine?

A: This machine is compatible with steel, alloy steel, and cast iron. Its hydraulic clamping system and heavy-duty frame handle tough materials, making it suitable for precision industrial applications.Q: When is the optimal time to perform maintenance on the machine?

A: Thanks to its low-maintenance, easy-access design and automatic lubrication system, routine checks can be performed during scheduled shift changes or as recommended in the machine's maintenance manual. The integrated design simplifies upkeep and minimizes downtime.Q: Where is this broaching machine most effectively used?

A: The machine is best suited for industrial environments where high-precision broaching is required, such as automotive, aerospace, and manufacturing plants that demand keyway, spline, or internal profile cutting.Q: What is the process of changing broaching tools on this model?

A: Tool changes are straightforward and quick, supported by the hydraulic chuck tool clamping system and the easy access design of the machine. This minimizes downtime and allows for efficient setup during production runs.Q: What are the benefits of using this broaching machine for industrial applications?

A: Operators benefit from its high precision, robust construction, reliability, and safety features like emergency stop and overload protection. Its automatic systems for lubrication and cooling ensure consistent performance, and the machine's versatility boosts overall productivity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Miscellaneous Machines Category

Famup Italy Pillar Drilling & Tapping Machine

Price 125000 INR / Piece

Minimum Order Quantity : 1 Piece

Surface Treatment : Other, Powder Coated

Control System : Other, Manual with electrical controls

Technology : Other, Precision Machining

Color : Green

Guinot Vertical Bandsaw Machine

Price 20000 INR / Piece

Minimum Order Quantity : 1 Piece

Surface Treatment : Other, Paint Coated

Control System : Other, Manual Control Panel

Technology : Other, HeavyDuty Cutting Technology

Color : Blue

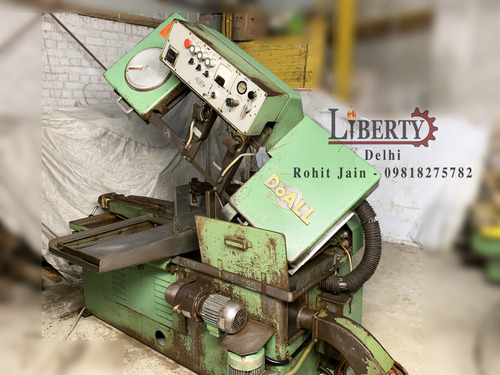

DoAll 325 mm Bandsaw Machine

Price 4000 USD ($)

Minimum Order Quantity : 1 Piece

Surface Treatment : Painted

Control System : Other, Buttons and Knobs Interface

Technology : Other, Mechanical cutting

Color : Green

Pedrazzoli Automatic Bandsaw Machine

Price 4100 USD ($)

Minimum Order Quantity : 1 Piece

Surface Treatment : Painted surface for durability, Other

Control System : Other, Automatic control panel

Technology : Automatic cutting technology, Other

Color : Green and orange

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry