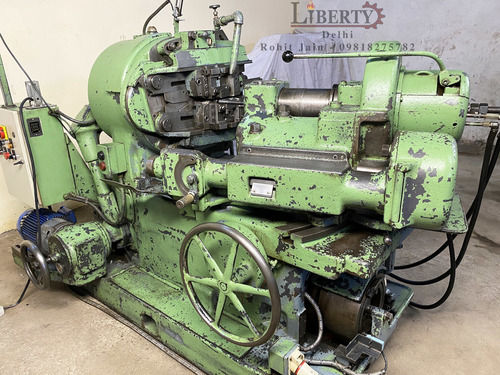

Gleason No. 14 Straight Bevel Coniflex Generator

Price 18000 INR/ Piece

Gleason No. 14 Straight Bevel Coniflex Generator Specification

- Power

- 5 HP

- Condition

- Used

- Dimension (L*W*H)

- Approx. 2000 mm x 1500 mm x 1800 mm

- Capacity

- Up to 355 mm diameter gears

- Machine Type

- Straight Bevel Coniflex Gear Generator

- Voltage

- 415 V

- Color

- Industrial Grey

- Weight

- Approx. 2000 kg

- Used For

- Precision gear cutting and generation of straight bevel gears

- Output

- Finished straight bevel gears

- Feature

- Manual and semi-automatic cycle options

- Control Type

- Mechanical controls

- Base Type

- Heavy-duty cast iron bed

- Spindle Speed

- Variable, up to 260 RPM

- Tool Holding

- Standard Gleason tooling

- Packing

- Standard export packing

- Max Face Width

- Up to 50 mm

- Gear Pitch Range

- 2.5 DP to 16 DP

- Noise Level

- Less than 80 dB(A)

- Safety Features

- Emergency stop and guard covers

- Model Number

- No. 14

- Floor Space Required

- Approx. 3.5 m²

- Max Gear Teeth

- Up to 80 teeth

- Max Gear Blank Diameter

- 355 mm

- Lubrication System

- Integrated manual lubrication

- Setup Time

- Approx. 30-45 minutes

Gleason No. 14 Straight Bevel Coniflex Generator Trade Information

- Minimum Order Quantity

- 1 Piece

- Main Domestic Market

- All India

About Gleason No. 14 Straight Bevel Coniflex Generator

Make - Gleason (USA)

Model - No. 14

Max. Pitch Diameter of Gear - 24

Max. Cone Distance - 12

Max. Face Width - 3.5

Stroke Length - 0.5 to 4.25

Max. Pitch - 3 D.P.

Pitch Angle - 5 Degree 42 to 105 Degree

Extreme Ratio - 10:1

Stroke Rate - 64 strokes/min to 495 strokes/min

- Double Cam Machine suitable for Roughing as well as Finishing.

- Complete with Setting Gauges, Change Gears, and a lot of other accessories.

- Operating Manuals, Electrical Drawings, Nc/75 Table etc. are available.

- Machine is in excellent working condition.

Video of The Machine -

Precision Gear Manufacturing

The Gleason No. 14 generator allows for the production of high-precision straight bevel gears, accommodating large gear blanks up to 355 mm in diameter and 80 teeth. Its variable spindle speed and rigorous mechanical controls ensure outstanding repeatability and accuracy every cycle.

Versatile and Efficient Operation

Manual and semi-automatic cycle options provide flexibility for various production needs. Thanks to quick setup timestypically between 30 and 45 minutesand standard Gleason tooling compatibility, manufacturers can adapt swiftly to different job requirements.

Designed for Safety and Durability

The machine is built on a heavy-duty cast iron bed, ensuring stability and longevity. Operator safety is a priority, with features like guard covers and an emergency stop. An integrated manual lubrication system ensures lasting performance and reduces maintenance downtime.

FAQs of Gleason No. 14 Straight Bevel Coniflex Generator:

Q: How does the Gleason No. 14 Straight Bevel Coniflex Generator operate in terms of control and cycle options?

A: This machine uses precision mechanical controls and offers both manual and semi-automatic cycles, giving operators flexibility based on production volume and complexity of the gear cutting process.Q: What is the process involved in setting up and cutting gears with this generator?

A: Setup typically takes between 30 and 45 minutes, involving the mounting of gear blanks, adjusting spindle speeds, and selecting standard Gleason tooling. Once set, the machine efficiently cuts straight bevel gears in a controlled, repeatable manner.Q: When should the integrated manual lubrication system be used?

A: Manual lubrication should be performed regularly before and during operation to ensure smooth movement of mechanical components and to extend the machines service life.Q: Where is the Gleason No. 14 generator typically installed and what are its space requirements?

A: It requires approximately 3.5 m of floor space and is typically installed in manufacturing, engineering, or gear production facilities where precision gear generation is needed.Q: What benefits does the Gleason No. 14 offer for gear manufacturers and suppliers?

A: Manufacturers benefit from its durable design, quick setup, ability to handle a wide pitch range and workpiece size, and efficient, safe operation. These features help deliver high-quality gears with minimal downtime.Q: Can this machine handle different gear sizes and teeth counts?

A: Yes, the generator can work with gear blanks up to 355 mm in diameter, face widths up to 50 mm, and up to 80 teeth, making it highly suitable for various industrial applications.Q: What safety measures are included with the Gleason No. 14?

A: To ensure operator safety, the machine comes equipped with an emergency stop function and guard covers to prevent accidental contact with moving parts during gear generation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

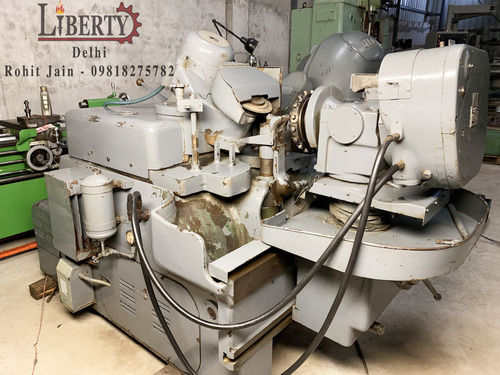

More Products in Bevel Gear Machines Category

Gleason No. 14 Straight Bevel Gear Generator

Price 14000 INR / Piece

Minimum Order Quantity : 1 Piece

Feature : Straight bevel gear generator

Condition : Used

Used For : Generating straight bevel gears

Color : Grey

Gleason No. 12 Straight Bevel Gear Generator

Price 4000 INR / Piece

Minimum Order Quantity : 1 Piece

Feature : Straight Bevel Gear Generator

Condition : Used

Used For : Generating straight bevel gears

Color : Green

Gleason 12-B Straight Bevel Gear Generator

Price 7000 INR / Piece

Minimum Order Quantity : 1 Piece

Feature : Sturdy construction, high precision, manual operation

Condition : Used

Used For : Manufacturing straight bevel gears

Color : Green

Gleason 13A Bevel Cutter Sharpener

Price 10800 USD ($)

Minimum Order Quantity : 1 Piece

Feature : Bevel cutter sharpener

Condition : Used

Used For : Sharpening bevel cutters

Color : Gray

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry