Price 100000 आईएनआर/ टुकड़ा

Specification

- प्रॉडक्ट टाइप

- मटेरियल

- Cast Iron

- काटने की मोटाई

- Dependent on tooling, standard up to 50 mm

- कटिंग स्पीड

- Variable speed up to 1500 RPM

- सीएनसी या नहीं

- स्वचालित ग्रेड

- कंट्रोल सिस्टम

- मैक्स। स्विंग डायमीटर

- 400 mm over bed; 560 mm in gap

- वोल्टेज

- 415 V, 3 Phase

- वजन (किग्रा)

- Approx. 1000 kg

- आयाम (एल* डब्ल्यू* एच)

- 1270 mm (Length) × 425 mm (Bed Width) × 610 mm (Height)

- क्षमता

- Up to 750 mm between centers

- फ़ीचर

- रंग

- Machine Grey

Trade Information

- Minimum Order Quantity

- 1 टुकड़ा

- मुख्य घरेलू बाज़ार

About

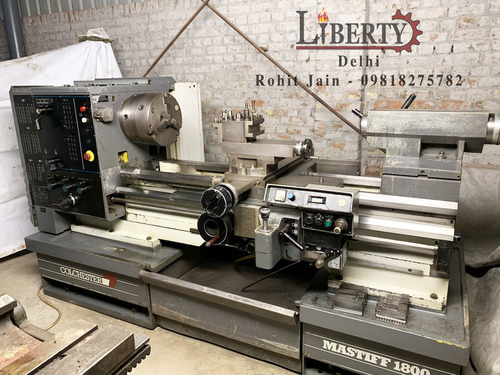

Make - Colchester (England)

Model - Triumph 2000

Center Height - 195 mm

Length of Job - 1270 mm

Max. Diameter of Job over Bed - 390 mm

Max. Diameter of Job over Cross-Slide - 230 mm

Max. Diameter of Job in Gap - 600 mm

Bed Width - 280 mm

Chuck Diameter - 250 mm

Spindle Speeds - 25 rpm to 2000 rpm

Spindle Bore - 55 mm

- Equipped with a 2-Axis DRO.

- Machine is in excellent working condition.

Video of the Machine -

Robust and Versatile Lathe for Every Workshop

Engineered for precision and strength, this gap bed lathe is built with an induction-hardened and ground cast iron bed, offering exceptional wear resistance and support during heavy-duty machining. Its design facilitates tasks ranging from general repairs to tool room projects, making it an essential addition to any production environment.

User-Friendly Manual Operation and Controls

The Colchester lathe emphasizes manual operation with a full gearbox and intuitive feed controls, allowing operators to achieve high levels of accuracy without the complexity of CNC software. Its comprehensive range of speed settings and thread-cutting options serve various materials and part requirements.

Multiple Applications and Durable Construction

Ideal for workshops, repair facilities, and tool rooms, this machines durable construction and wide capacityup to 750 mm between centersaccommodate diverse turning, facing, and threading processes. The gap bed feature enables machining of larger diameter workpieces for maximum versatility.

FAQs of Colchester England 1270 mm Length Gap Bed Lathe Machine:

Q: How does the gap bed design benefit users working with large workpieces?

A: The gap bed design allows the operator to remove a section of the bed, increasing the swing diameter to 560 mm. This enables the machining of larger diameter workpieces that would otherwise not fit over the standard bed area, offering flexibility for a wider range of jobs.Q: What types of materials can this lathe machine handle effectively?

A: With its sturdy cast iron construction and induction-hardened bed, the machine can efficiently machine metals such as steel, cast iron, brass, and aluminum, as well as some plastics, depending on tooling and cutting conditions.Q: When should the variable speed function and threading options be used?

A: The variable speed feature, ranging up to 1500 RPM, should be adjusted based on material type and desired finish. The metric and imperial threading options (0.214 mm; 460 TPI) are used when precise threads are required for differing standards or specific applications.Q: Where is this lathe machine commonly installed and operated?

A: This lathe is typically used in general workshops, engineering repair shops, and tool rooms. Its robust design also suits light manufacturing environments where precision and adaptability are required.Q: What is the process for changing speeds or threading settings on the machine?

A: Speeds and threading settings are changed manually via the built-in gearbox and feed controls. Operators select the appropriate gear for the required operation, ensuring the lathe runs at optimal speed for the job and material at hand.Q: How does the induction-hardened and ground bed enhance performance?

A: The induction-hardened and ground bed provides a wear-resistant and smooth surface, reducing vibration during operation. This increases accuracy, extends machine life, and ensures consistent machining results.Q: What are the usage benefits of the built-in coolant pump?

A: The fitted coolant pump maintains optimal cutting temperatures, reduces tool wear, and helps achieve a better surface finish. Its especially beneficial during extended operations or when machining hard materials.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in खराद मशीन Category

TOS SU-90A 2800 मिमी हैवी ड्यूटी लेथ मशीन

माप की इकाई : टुकड़ा/टुकड़े

न्यूनतम आदेश मात्रा : 1

मूल्य या मूल्य सीमा : आईएनआर

मूल्य की इकाई : टुकड़ा/टुकड़े

वोल्टेज : 415 V, 3 Phase

मटेरियल : Highgrade Cast Iron

कोलचेस्टर स्टूडेंट 1800 लेथ मशीन

माप की इकाई : टुकड़ा/टुकड़े

न्यूनतम आदेश मात्रा : 1

मूल्य या मूल्य सीमा : आईएनआर

मूल्य की इकाई : टुकड़ा/टुकड़े

वोल्टेज : 415 V, 3 Phase

मटेरियल : Cast Iron

स्कोडा SR1250 हैवी ड्यूटी लेथ मशीन

माप की इकाई : टुकड़ा/टुकड़े

न्यूनतम आदेश मात्रा : 1

मूल्य या मूल्य सीमा : आईएनआर

मूल्य की इकाई : टुकड़ा/टुकड़े

वोल्टेज : 415 V, 3 Phase, 50 Hz

मटेरियल : Cast Iron

कोलचेस्टर मास्टिफ़ लेथ मशीन

माप की इकाई : टुकड़ा/टुकड़े

न्यूनतम आदेश मात्रा : 1

मूल्य या मूल्य सीमा : यूएसडी ($)

वोल्टेज : 415V, 50Hz, 3 Phase

मटेरियल : Cast Iron Body and Hardened Steel Components

जांच भेजें

जांच भेजें जांच भेजें

जांच भेजें