Price 100000 आईएनआर/ टुकड़ा

Specification

- रंग

- Green

- पावर

- Main Motor: 5 HP

- वोल्टेज

- 415V, 3 Phase

- फ़ीचर

- High Performance, Durable Construction, Vertical Gear Cutting Capability

- वज़न

- Approx. 3 to 5 Tons

- के लिए इस्तेमाल किया गया

- Gear Shaping, Precision Gear Cutting

- क्षमता

- Gear Diameter up to 400 mm

- आयाम (एल* डब्ल्यू* एच)

- Approx. 2800 x 1400 x 2000 mm

- शर्त

- Used / Second Hand

- मशीन का प्रकार

- Gear Shaper Machine

- आउटपुट

- Precise External & Internal Gear Cutting

- Control Type

- Manual with Mechanical Operations

- Spindle Speed

- Variable, 37-150 RPM

- Number of Strokes per Minute

- Adjustable (Approx. 60-300 SPM)

- Noise Level

- Below 80 dB

- Coolant System

- Integrated

- Table Travel

- Longitudinal & Cross Travel Provided

- Max Gear Width

- 80 mm

- Installation Area Required

- Approx. 15 sq. ft.

- Feed Rate

- Adjustable

- Module Range

- Up to 6 Module

- Stroke Length

- 160 mm

- Precision Level

- ±0.02 mm

- Lubrication System

- Centralized Manual Lubrication

- Cutter Diameter

- Up to 127 mm

- Drive Type

- Gear Driven with Belt Assistance

- Table Diameter

- 400 mm

Trade Information

- Minimum Order Quantity

- 1 टुकड़ा

- मुख्य घरेलू बाज़ार

About

Make - Fellows-Herbert (England / USA)

Max. Module Capacity - 4 Modules

Max. Gear Diameter - 250 mm

Max. Stroke Length - 60 mm

Spindle Diameter - 69.5 mm

Stroke Rate - 156 strokes/min to 515 strokes/min

Height between Table to Spindle Body - 150 mm

- Complete with Change Gears.

- Machine is in excellent working condition.

Video of The Machine -

Exceptional Gear Shaping Precision

Achieve precise gear shaping with the Fellows Herbert Gear Shaper Machine, which boasts a precision level of 0.02 mm. Its robust design ensures consistent accuracy for both external and internal gear cutting, making it ideal for industries where reliable gear production is critical. The machine's variable speed settings and adjustable feed offer superior control, ensuring optimal results for every shaping job.

Comprehensive Mechanical Control

This gear shaper is operated manually with mechanical controls, giving experienced operators full command over the shaping process. Adjustable table travel-both longitudinal and cross-together with a modular cutter capability (up to 6 module), supports a wide variety of gear sizes and types. The central lubrication and integrated coolant system contribute to smooth operation and extended machine life.

Built for Versatility and Longevity

The machine accommodates gear widths up to 80 mm, cutter diameters up to 127 mm, and offers a stroke rate of 60-300 strokes per minute. Constructed for high performance and durability, the Fellows Herbert Gear Shaper Machine meets the demanding needs of manufacturers, exporters, importers, and suppliers in the United Kingdom and beyond. Its sturdy, green build and efficient 5 HP main motor ensure dependable operation.

FAQ's of Fellows Herbert Gear Shaper Machine:

Q: How does the Fellows Herbert Gear Shaper Machine achieve high-precision gear cutting?

A: The machine features a precision level of 0.02 mm, adjustable spindle speeds (37-150 RPM), and a rigid structure. Together, these factors enable consistent and accurate external and internal gear shaping, suitable for demanding industrial applications.Q: What range of gear sizes can this machine handle?

A: The machine accommodates gear diameters up to 400 mm, gear widths up to 80 mm, and cutter diameters up to 127 mm. It also supports modules up to 6, making it versatile for various gear shaping tasks.Q: When is manual control beneficial for gear cutting operations?

A: Manual mechanical operations allow skilled operators to finely adjust settings, such as feed rate, stroke rate (60-300 SPM), and table travel. This level of control is crucial for custom or intricate gear shaping jobs requiring tailored adjustments.Q: Where is this machine commonly used?

A: This gear shaper is suitable for manufacturing facilities, gear repair workshops, and heavy engineering industries. Its capabilities make it popular with exporters, importers, manufacturers, and suppliers, especially in markets like the United Kingdom.Q: What is the process for maintaining this gear shaper machine?

A: Routine maintenance involves using the centralized manual lubrication system to keep components moving smoothly, checking the integrated coolant system, and conducting regular inspections during non-operation hours to ensure longevity and optimal function.Q: How does the adjustable table travel enhance machine usage?

A: Longitudinal and cross table travel allow for flexible positioning of workpieces, accommodating different gear sizes and complex shaping needs. This adaptability enhances the range of gear profiles the machine can produce.Q: What are the key benefits of using this used Fellows Herbert Gear Shaper Machine?

A: Benefits include high shaping accuracy, robust durability, adjustable operational parameters, integrated lubrication and coolant systems, low noise output (below 80 dB), and cost-effectiveness compared to new equipment.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in गियर शेपर्स Category

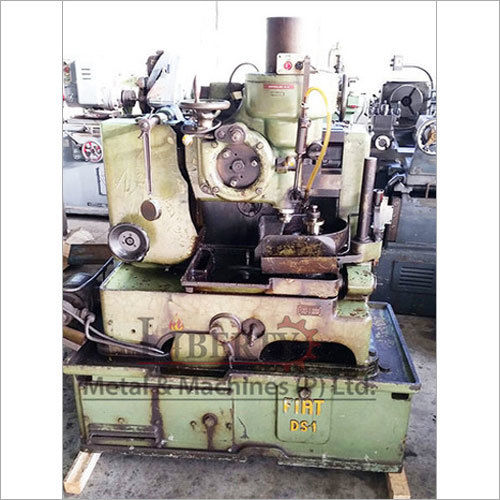

फिएट डीएस 1 गियर शेपर

क्षमता : Max workpiece diameter: 320 mm

शर्त : Used

मशीन का प्रकार : Gear Shaper

के लिए इस्तेमाल किया गया : Precision gear cutting operations

आउटपुट : High accuracy gears

फ़ीचर : High productivity, robust structure, easy setup

साइक्स V10C गियर शेपर मशीन

क्षमता : Maximum gear diameter: 1000 mm

शर्त : Used

मशीन का प्रकार : Gear Shaper Machine

के लिए इस्तेमाल किया गया : Highprecision internal and external gear cutting

आउटपुट : Highprecision gears

फ़ीचर : Heavyduty, highaccuracy, robust construction, versatile operation

TOS OH-4 गियर शेपिंग मशीन

क्षमता : Maximum gear diameter: 400 mm

शर्त : Used

मशीन का प्रकार : Gear Shaping Machine

के लिए इस्तेमाल किया गया : External and internal gear shaping

आउटपुट : Mechanical transmission gears and similar items

फ़ीचर : Precision gear shaping, sturdy design, high productivity

जांच भेजें

जांच भेजें जांच भेजें

जांच भेजें