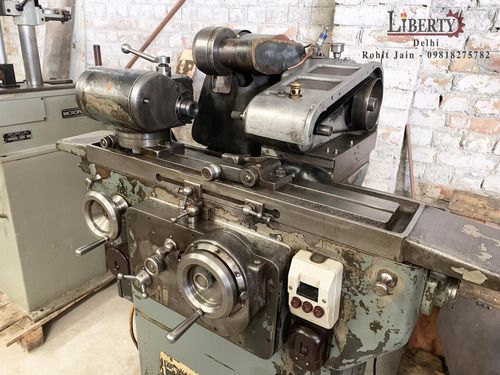

Morara Bore Grinding Machine

Morara Bore Grinding Machine Specification

- Rotation

- Clockwise/Counter Clockwise

- Model

- Morara

- Product Type

- Bore Grinding Machine

- General Use

- Internal/Bore Grinding Operations

- Material

- Cast Iron and Steel

- Type

- Internal Grinder

- Capacity

- Heavy Duty

- Weight (kg)

- Approx. 950 kg

- Computerized

- No

- Automatic

- No (Manual)

- CNC Or Not

- Conventional

- Control System

- Manual

- Table Size

- 300 mm x 120 mm

- Table Slide Way

- V-Flat

- Grinding Wheel Size

- 250 mm

- Grinding Wheel Speed

- 2200 RPM

- Grinding Length

- 125 mm

- Floor Space

- 1400 mm x 1300 mm

- Spindle Speed

- Up to 24000 RPM

- Power

- 3 HP

- Voltage

- 415 V

- Dimension (L*W*H)

- 1400 x 1300 x 1700 mm

- Feature

- Precision Grinding, Rigid Construction

- Color

- Industrial Green/Grey

- Maximum Workpiece Diameter

- 250 mm

- Maximum Workpiece Length

- 350 mm

- Grinding Accuracy

- ±0.002 mm

- Operator Interface

- Simple Handwheel Controls

- Coolant System

- Integrated

- Lubrication Type

- Automatic Centralized Lubrication

- Chuck Type

- Manual Chuck

- Noise Level

- Low

- Application

- Heavy Duty Bore and Internal Grinding

About Morara Bore Grinding Machine

Make - Morara (Italy)

- Internal Diameter of Job - 100 mm

- Outer Diameter of Job - 200 mm

- Length of Job - 100 mm

- Face Grinding Wheel Diameter - 100 mm

- With Face Grinding attachment.

- Hydraulic Table Movement.

- Hydraulic work-head Rotation.

- 2 speed Spindle Rotation.

- Automatic Depth Adjustment "Auto-cut"

- Complete with Coolant tank and pump.

- Machine is in excellent working condition.

Precision and Durability in Heavy Duty Grinding

Built with a rigid cast iron and steel construction, the Morara Bore Grinding Machine delivers exceptional stability and accuracy for internal and bore grinding operations. Its heavy-duty capacity, coupled with automatic lubrication and an integrated coolant system, allows for sustained use without compromising on grinding precision or machine longevity. Suited to demanding industrial environments, the unit ensures fine tolerances with grinding accuracy of 0.002 mm.

Efficient and User-Friendly Manual Operation

This conventional, non-CNC internal grinder features a straightforward handwheel control system, allowing operators to execute intricate grinding tasks with confidence and ease. The manual chuck, simple controls, and clear interface significantly reduce setup complexities. The automatic centralized lubrication further streamlines maintenance, helping minimize downtime and keeping the focus on productivity.

FAQs of Morara Bore Grinding Machine:

Q: How does the Morara Bore Grinding Machine maintain high grinding accuracy during operations?

A: The machine utilizes a rigid cast iron and steel structure, an integrated coolant system, and automatic centralized lubrication to minimize vibrations and thermal expansion, maintaining a grinding accuracy of 0.002 mm even during extended use.Q: What types of workpieces can be processed on this machine?

A: It is designed for heavy-duty bore and internal grinding, suitable for workpieces with a maximum diameter of 250 mm and a maximum length of 350 mm, commonly used for precision components in metal manufacturing.Q: When should the lubricant system be serviced?

A: The lubrication system is automatic and centralized, reducing the need for frequent manual checks. However, its advisable to follow a scheduled maintenance plan, inspecting the lubrication unit at regular intervals as outlined in the user manual, or after every major production run.Q: Where can the Morara Bore Grinding Machine be installed?

A: Given its compact floor space of 1400 mm x 1300 mm, this machine is suitable for installation in industrial workshops, tool rooms, and manufacturing plants. Ensure the area has the required 415 V power supply and adequate space for operation and maintenance access.Q: What are the steps in the general grinding process on this machine?

A: The process involves securing the workpiece using the manual chuck, adjusting the grinding wheel (250 mm size) and handwheel controls, and selecting the spindle speed up to 24,000 RPM. The operator monitors the operation, assisted by the integrated coolant and lubrication systems for optimal grinding results.Q: How does the design benefit the operator and overall productivity?

A: Manual handwheel controls and a straightforward interface simplify operation, while the automatic lubrication and integrated coolant reduce routine maintenance. The machines low noise level and rigid build also promote a more comfortable and efficient working environment.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Internal Grinding Machine Category

Voumard 650 mm Diameter Internal Grinder Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic : Other, No, manual operation

CNC Or Not : Other, Not CNC (Conventional)

Control System : Other, Manual with dial gauges

Product Type : Internal Grinder

Voumard Type 5s Long Table Internal Grinding Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic : No

CNC Or Not : Other, Not CNC (Manual)

Control System : Other, Manual lever and dial system

Product Type : Internal Grinding Machine

Spandau Internal Grinding Machine

Price 1100 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Automatic : No

CNC Or Not : Not CNC, Other

Control System : Manual

Product Type : Internal Grinding Machine

TOS BDA80 Internal Grinding Machine

Price 1100 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Automatic : No

CNC Or Not : Other, Not CNC

Control System : Manual

Product Type : Internal Grinding Machine

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry