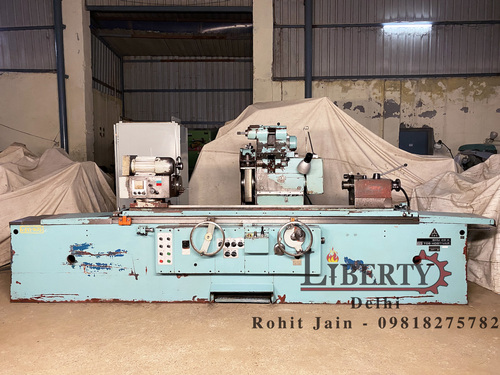

Morara Italy Micro/E Automatic Cylindrical Grinding Machine

Price 100000 INR/ Piece

Morara Italy Micro/E Automatic Cylindrical Grinding Machine Specification

- Computerized

- Yes

- Automatic

- Yes

- Control System

- PLC Control

- Voltage

- 240 Volt (v)

- Feature

- Environmental Friendly

- Color

- White

Morara Italy Micro/E Automatic Cylindrical Grinding Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Main Domestic Market

- All India

About Morara Italy Micro/E Automatic Cylindrical Grinding Machine

Make - Morara (Italy)

Model - Micro/E

Center Height - 108 mm

Max. Job Diameter - 215 mm

Max. Grinding Length of Job - 250 mm

Max. Clamping Length of Job - 355 mm

Grinding Wheel Size - Diameter 400 mm x 60 mm Width

Work-Head Speeds - 0 rpm to 670 rpm (Infinitely Variable)

Range of Table Rotation - +10 degree to -10 degree

- Features of Delay, Auto-Cut, Plunge Grinding, Auto-Compensation etc.

- Features of Automatic Wheel Retraction, Spark-Out, etc.

- Complete Auto-Cycle Working suitable for Shaft Grinding & Plunge Grinding.

- Operating Manual, Electrical Drawings, PLC Program etc are available.

- Complete with Coolant Filtration Unit, Coolant Tank & Pump.

- Machine is in excellent working condition.

Video of The Machine -

Advanced Automation for Efficiency

Equipped with fully automatic and computerized PLC controls, the Morara Micro/E streamlines grinding processes, reducing manual intervention. It ensures high precision and repeatability in every cycle, making it perfect for continuous industrial operations and increasing overall productivity.

Eco-Friendly and Reliable Operation

Designed with environmental considerations in mind, this cylindrical grinding machine minimizes energy consumption and reduces waste. Its robust construction paired with a 240 Volt power supply ensures reliability while supporting greener manufacturing goals.

FAQ's of Morara Italy Micro/E Automatic Cylindrical Grinding Machine:

Q: How does the PLC control system enhance the operation of the Morara Micro/E Cylindrical Grinding Machine?

A: The PLC control system automates operations, providing precise control over grinding parameters. This reduces manual errors, increases efficiency, and allows operators to program complex tasks easily, leading to consistent and high-quality results every time.Q: What types of industries are best suited to use this automatic cylindrical grinding machine?

A: Industries involved in high-precision manufacturing, such as automotive, aerospace, tool making, and equipment suppliers, benefit most from this machine. Its versatility and accuracy cater to diverse production needs, from small batches to mass manufacturing.Q: When should I consider choosing an automatic, computerized grinding machine over a manual model?

A: Choose an automatic, computerized model like the Morara Micro/E when you require higher productivity, superior consistency, minimal operator intervention, and the ability to handle complex grinding operations. This is especially essential for large-scale or continuous operations.Q: Where is the Morara Italy Micro/E Cylindrical Grinding Machine commonly installed?

A: This machine is commonly installed in manufacturing plants, workshops, and industrial production facilities where high-precision cylindrical grinding is essential. It is favored by manufacturers, exporters, importers, suppliers, and traders alike.Q: What is the process for using the Morara Micro/E Cylindrical Grinding Machine?

A: Begin by setting up the workpiece and configuring the desired grinding parameters via the computerized PLC interface. The machine then automatically carries out the grinding cycle, ensuring uniformity and accuracy, while minimizing waste and operator involvement.Q: How does the machine support environmental sustainability goals?

A: The Morara Micro/E is designed as an environmentally friendly unit, optimizing energy use and reducing material waste through efficient, automated operation. This supports companies in meeting modern sustainability standards and reducing their ecological footprint.Q: What are the key benefits of using this Italian-made cylindrical grinding machine?

A: Key benefits include high precision, efficiency, strong environmental credentials, reliable 240V operation, robust construction, and adaptability to various industrial applications. These factors collectively enhance manufacturing competitiveness and product quality.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cylindrical Grinder Category

TOS BHU40A 1500 mm Universal Cylindrical Grinder

Price 60000 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : Manual

General Use : Industrial Grinding Operations

Capacity : 1500 mm between centers

Color : Other, Standard Grey/Blue

Fortuna Germany 1000 mm Cylindrical Grinder Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : Manual

General Use : Precision grinding of cylindrical surfaces

Capacity : 1000 mm

Color : Other, Standard industrial grey

Hans Sielemann 800 mm Rotary Table type External, Internal & Face Grinder Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : Other, PLC / Manual Control

General Use : External, Internal & Face Grinding of precision components

Capacity : 800 mm rotary table

Color : Other, Industrial Green/Grey

G Rastelli R7A Cylindrical Grinding Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : Other, Manual with Electrical Controls

General Use : Industrial, Precision Grinding

Capacity : Maximum Grinding Diameter: 200 mm

Color : Other, Industrial Grey / Green

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry