Call: 08045478939

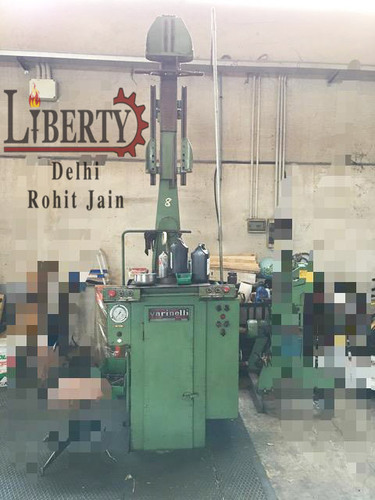

Varinelli Vertical Broaching Machine

MOQ : 1 Piece

Varinelli Vertical Broaching Machine Specification

- Hardness

- Up to 65 HRC (depending on tool)

- Cutting Accuracy

- 0.01 mm

- Machine Type

- Vertical Broaching Machine

- Shape

- Vertical Structure

- Operation Type

- Hydraulic/Electro-mechanical Operation

- Features

- High rigidity construction, Accurate guideways, Rapid & return stroke selection switch, Safety interlocks, Easy tool changing, High Precision

- Cutter Type

- Single & Multiple Tool Holder

- Tool Type

- Vertical Broaching Tool

- Brooches Type

- Internal, External, Surface, Spline Broach capability

- Cutting Force

- Up to 100 kN (model dependent)

- Cutting Capacity

- Broaching capacity up to 10 tons

- Coating

- Uncoated

- Cutting Speed

- Variable, up to 10 m/min (depends on model)

- Operate Method

- Automatic and Manual options

- Length

- Broach stroke length up to 2000 mm (varies by machine)

- Material

- Heavy-duty Cast Iron Frame, Hardened Steel Components

- Diameter

- Broaching up to 300 mm (model and tool dependent)

- Maximum Torque

- N/A (Broaching machines use linear force rather than torque)

- Processing Type

- Metal Broaching

- Coolant System

- High-efficiency Coolant System

- Weight

- 3500 kg (approx, model dependent)

- Applications

- Automotive, Aerospace, Industrial Gear Manufacturing, Keyway, Spline, Internal Profiles

- Blade Size

- Customizable as per broach & application

- Power Requirement

- 3 Phase, 415V, 50Hz

- Table Size

- Up to 600 mm x 600 mm (model dependent)

- Safety

- Electrical & Mechanical Overload Protection

- Control System

- PLC Controlled (optional)

- Main Motor Power

- Up to 15 kW (varies per model)

- Lubrication System

- Automatic Centralised Lubrication

About Varinelli Vertical Broaching Machine

Varinelli Vertical Broaching Machine

- Make - Varinelli (Italy)

- Model - BVP 10/1320

- Capacity - 10 Tons

- Stroke Length - 1320 mm

- Work Speed - 0 to 3.5 m/min

- Return Speed - 0 to 21 m/min

- Machine is in excellent working condition.

Exceptional Precision and Versatility

The Varinelli Vertical Broaching Machine is engineered for high-accuracy metal processing, achieving cutting accuracies of 0.01 mm. Its customizable table and blade sizes accommodate a wide range of workpieces and broaching applications, including internal, external, and spline profiles in numerous industrial sectors.

Robust Performance and Safety Features

Built with heavy-duty cast iron and hardened steel, the machine handles broaching capacities up to 10 tons. Electrical and mechanical overload protection systems, as well as safety interlocks, help ensure operator safety and machine longevity during both hydraulic and electro-mechanical operation.

Effortless Operation and Maintenance

The included PLC control (optional), rapid stroke selection switch, easy tool change mechanism, and centralised automatic lubrication simplify both usage and upkeep. This design promotes minimal downtime and maximum efficiency in high-volume production environments.

FAQs of Varinelli Vertical Broaching Machine:

Q: How is the Varinelli Vertical Broaching Machine operated?

A: The machine offers both automatic and manual operation modes. With optional PLC control, users can program sequences for repeatable precision or manage processes manually for custom tasks. Rapid & return stroke selection and safety interlocks further streamline operations.Q: What materials and applications can this broaching machine handle?

A: The heavy-duty cast iron frame and hardened steel components are suitable for precision broaching of metals used in automotive, aerospace, and industrial gear manufacturing. Applications include keyways, splines, internal and external profiles, and various broach strokes up to 2000 mm.Q: When should the lubrication and coolant systems be serviced?

A: The machine features an automatic centralised lubrication system and a high-efficiency coolant system. Routine checks as recommended in the user manual ensure these systems function optimally, but major servicing intervals depend on production intensity and usage duration.Q: Where can the Varinelli Vertical Broaching Machine be installed?

A: This broaching machine requires a stable industrial setting with a power supply of 3 Phase, 415V, 50Hz. Adequate floor space for the model size and provision for safe material handling are essential for efficient installation and operation.Q: What is the process for changing broaching tools and blades?

A: The machine is designed for easy tool changing, reducing downtime between operations. Blade and tool holders can be swapped in accordance with the workpiece profile, and blade sizes can be customized to suit various broaching applications and broach types.Q: How does the machine ensure high cutting precision and durability?

A: Accurate guideways, high rigidity construction, and precise hydraulic or electro-mechanical actuation deliver consistent cutting accuracy (0.01 mm), while overload protection features and quality materials maximize machine lifespan and reliability.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Broaching Machine Category

Varinelli Vertical Broaching Machine

Machine Type : Broaching Machine

Cutting Accuracy : High

Operation Type : Other, Cutting

Shape : Vertical

Cutter Type : Broaching Cutter

Features : Precision Cutting Vertical Broaching

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry