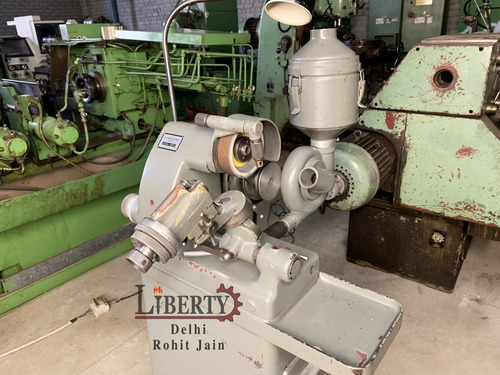

Breda AFP50 Drill Grinding Machine

Breda AFP50 Drill Grinding Machine Specification

- Operation Type

- Manual/Semi-Automatic

- Coating

- Uncoated (Standard Machine Grey Paint)

- Coating Type

- No Special Coating

- Material

- Cast Iron, Steel, Aluminum (for housing and working parts)

- Tool Type

- Drill Bit Grinder

- Cutting Speed

- Adjustable, up to 80 m/min

- Features

- Robust Construction, Precise Angle Adjustment, Suitable for Heavy-Duty and Workshop Use

- Drill Bits Types

- HSS, Carbide, Standard Twist Drills

- Cutting Capacity

- Drills up to 50 mm diameter

- Shape

- Rectangular Base with Integrated Grinding Mechanism

- Cutting Accuracy

- High precision (0.05 mm)

- Cutter Type

- Grinding Wheel-Based Cutter

- Length

- Approx. 980 mm

- Operate Method

- Manual and Semi-Automatic

- Machine Type

- Drill Grinding Machine

- Hardness

- Body: Rigid Cast Iron Structure, Working parts: Tempered Steel

- Cutting Force

- Mechanical Transmission, Optimized for Drill Grinding

- Diameter

- Max. 50 mm (drill diameter for grinding range)

- Maximum Torque

- N/A (not directly applicable to grinding)

- Processing Type

- Drill Bit Grinding and Re-sharpening

- Blade Size

- For Drill Bits Up To 50 mm Diameter

- Application

- Sharpening and Regrinding of Drill Bits

- Model

- AFP50

- Clamping Device

- Included for Various Drill Types

- Adjustable Angles

- Point Angle & Clearance Angle Adjustable from 80° to 140°

- Voltage

- 380 V / 50 Hz, 3 Phase

- Net Weight

- Approx. 300 kg

- Grinding Wheel Size

- 200 mm Diameter

- Coolant System

- Built-in Coolant Pump with Tank

- Safety Features

- Full Cover Guards on Grinding Wheel, Emergency Stop

- Power

- 1.1 kW Motor

About Breda AFP50 Drill Grinding Machine

Make - Breda (Italy)

Model - AFP50

Diameter of the Drill to be Sharpened - 6 mm to 55 mm

Minimum & Maximum Vertex Angle - 80o to 180o

Stroke of Spindle Support - 90 mm

Grinding Wheel Diameter - 225 mm

Speed of Grinding Wheel - 2550 rpm

- Sharpening of 2-point, 3-point and 4-point Drills possible.

- With Automatic Feed Travel and Depth Adjustment.

- Complete with 2 spare sets of jaws and coolant pump.

- Machine is in excellent working condition.

Video linl-https://youtu.be/pYGTIaJ7g1Y

Precision and Efficiency for Drill Bit Grinding

The Breda AFP50 is engineered to deliver high-precision grinding for a wide array of drill bits, providing adjustable point and clearance angles for custom applications. Its powerful motor and integrated coolant system help achieve fine, consistent edges, maximizing drill bit longevity for industrial, manufacturing, and heavy-duty workshop environments.

User-Friendly and Versatile Operation

This drill grinder supports both manual and semi-automatic operation modes, catering to professionals who require flexibility and reliability. The included clamping device accommodates various drill types, streamlining the setup process and reducing downtime during angle adjustments or drill changes.

FAQs of Breda AFP50 Drill Grinding Machine:

Q: How do I operate the Breda AFP50 Drill Grinding Machine?

A: To operate the AFP50, securely clamp the drill bit using the included device, set the desired point and clearance angles (between 80 and 140), and select the appropriate cutting speed. You may operate the machine manually or use the semi-automatic function, ensuring the built-in coolant pump is activated to maintain optimal temperature during grinding.Q: What types of drill bits can be sharpened with the AFP50?

A: The machine is suitable for sharpening and regrinding High Speed Steel (HSS), carbide, and standard twist drill bits up to a maximum diameter of 50 mm, making it versatile for different workshop needs.Q: When should I use the built-in coolant system?

A: The coolant system should always be used during grinding operations to prevent overheating, preserve drill material integrity, and ensure a smooth, precise finish on the bit edges.Q: Where can the Breda AFP50 be installed?

A: Thanks to its compact size and rugged construction, the AFP50 is ideal for installation in industrial workshops, manufacturing plants, and maintenance departments with access to a 380 V, 3-phase power supply.Q: What is the grinding process for drill bits on this machine?

A: The grinding process involves clamping the drill bit, adjusting angles, and initiating the grinding wheel. Maintain steady manual or semi-automatic feed and monitor the grinding operation through the full-cover safety guards, ensuring the coolant is flowing effectively.Q: How does the adjustable angle feature benefit users?

A: The ability to adjust both point and clearance angles from 80 to 140 provides operators with greater control over drill bit geometry, resulting in better cutting performance and extended tool life across different materials and drilling applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Tool & Cutter Grinder Category

TOS BN101 Universal Tool and Cutter Grinder

Price 21000 INR

Minimum Order Quantity : 1 Piece

Tool Type : Universal tool & cutter grinder

Machine Type : Manual universal tool and cutter grinder

Features : Swiveling work table, adjustable headstock, coolant attachment, precise graduations

Operation Type : Other, Grinding, sharpening

La Parora Italy Tool Sharpening Machine

Price 100000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Tool Type : Tool Sharpening Machine

Machine Type : Benchtype tool sharpening machine

Features : Coolant tank and pump included, robust construction, adjustable supports, made in Italy

Operation Type : Other, Manual operation

Tacchella 5MS Tool Cutter Grinder

Price 3000 INR / Piece

Minimum Order Quantity : 1 Piece

Tool Type : Cutter Grinder

Machine Type : Tacchella 5MS Tool Cutter Grinder

Features : Durable High efficiency

Operation Type : Other, Grinding and Cutting

Deckel Single-Lip Cutter Grinder

Price 1100 USD ($)

Minimum Order Quantity : 1 Piece

Tool Type : Cutter grinder

Machine Type : Deckel Cutter Grinder

Features : Compact design Manual operation mechanism

Operation Type : Grinding and sharpening, Other

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry