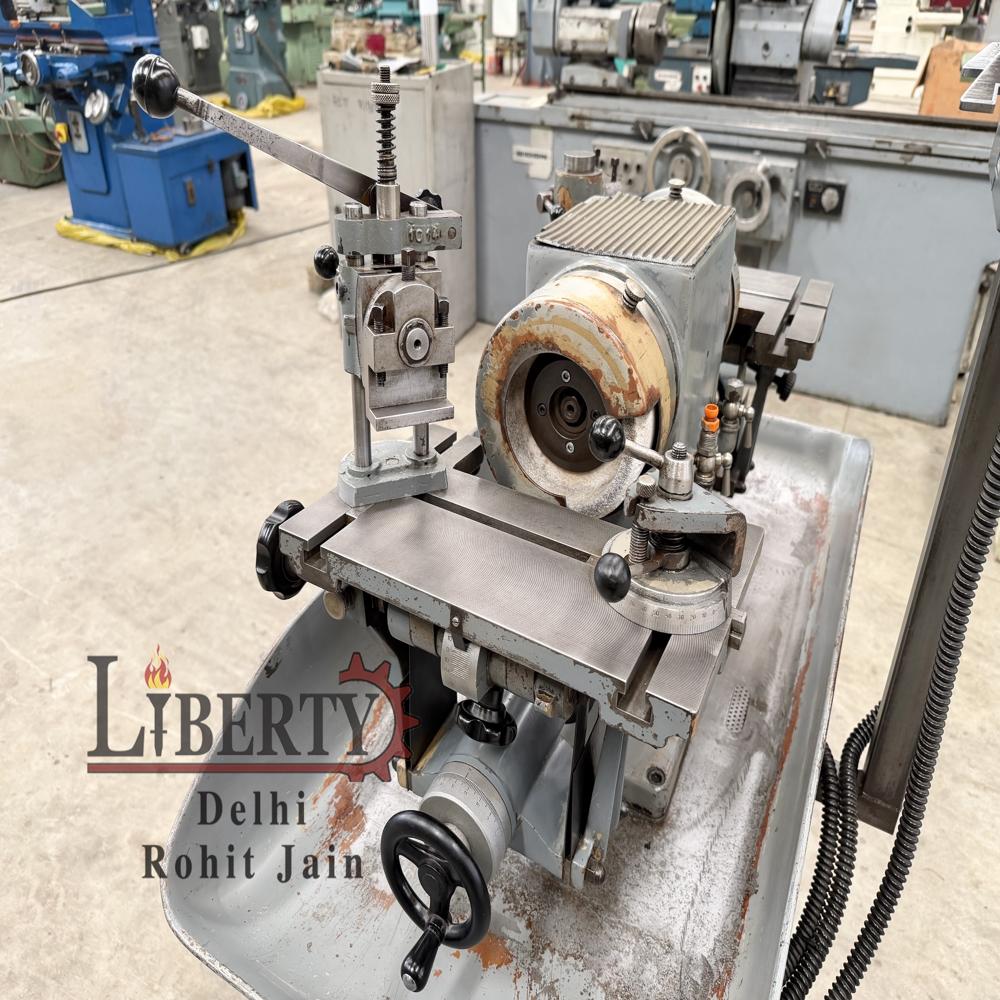

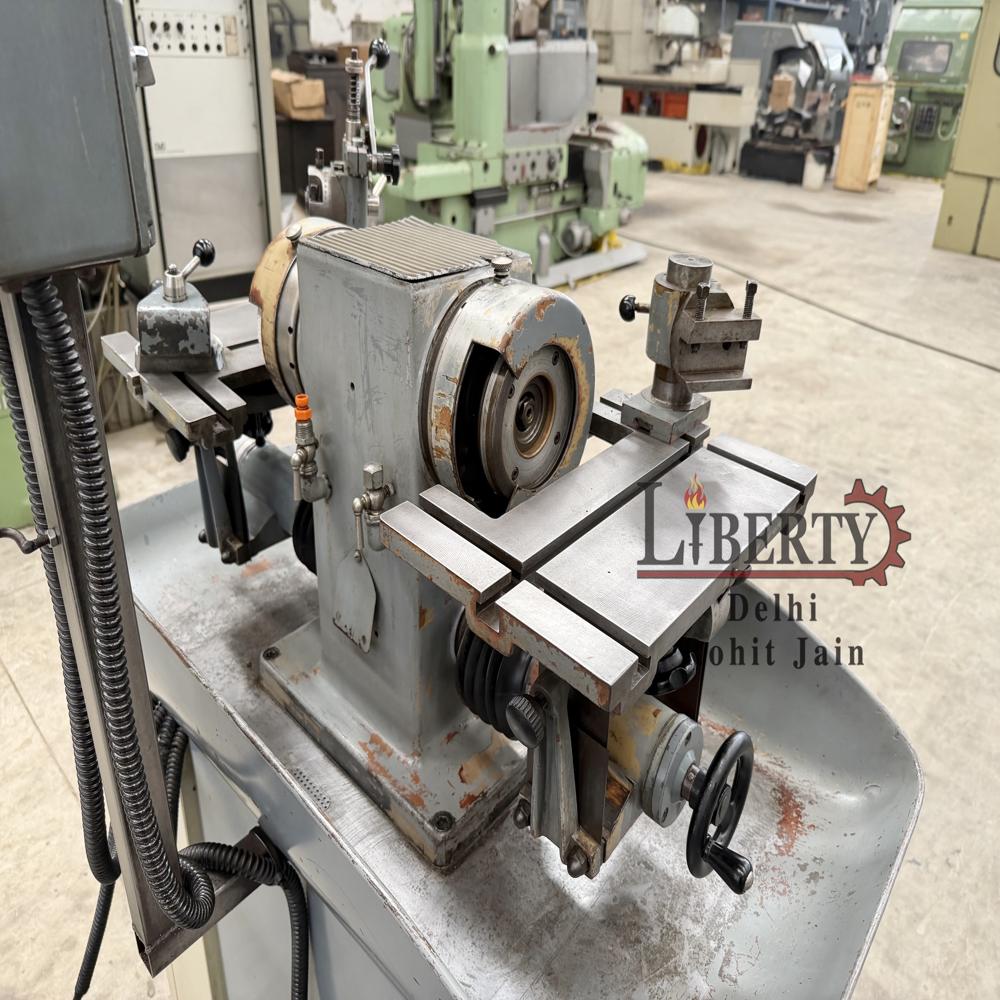

La Parora Italy Tool Sharpening Machine

Price 100000.0 INR/ Piece

La Parora Italy Tool Sharpening Machine Specification

- Material

- Industrial-grade steel & alloy construction

- Operation Type

- Manual operation

- Length

- Machine Length Approximately 800 mm

- Cutting Capacity

- Up to standard tooling sizes

- Shape

- Rectangular body with integrated support and sharpening assembly

- Cutting Force

- High precision, suitable for industrial tool sharpening

- Tool Type

- Tool Sharpening Machine

- Usage

- La Parora (Italy) make Tool Sharpening Machine in excellent working condition. The model of the machine is Beta 150 and it is complete with its Coolant Tank and Pump. The technical details are as follows -

- Cutter Type

- Tool Sharpener Wheel

- Cutting Accuracy

- High Accuracy Sharpening

- Features

- Coolant tank and pump included, robust construction, adjustable supports, made in Italy

- Hardness

- Compatible with carbide and HSS tools

- Operate Method

- Manual lever/feed

- Cutting Speed

- Variable (depends on setting)

- Machine Type

- Bench-type tool sharpening machine

- Diameter

- Grinding Wheel 150 mm

- Processing Type

- Grinding / Sharpening

- Technical Details

- Complete with coolant system, durable construction, easy-to-use controls

- Model

- Beta 150

- Included Accessories

- Coolant tank and pump

- Voltage

- 3-Phase, 400V (Typical for European machines)

- Condition

- Excellent working condition

- Weight

- Approx 120 kg

- Usage

- Sharpening of end mills, drills, lathe tools, and other industrial cutting tools

- Electric Motor Power

- Approx 0.55 kW / 0.75 HP

About La Parora Italy Tool Sharpening Machine

High-Precision Sharpening for Industrial Tools

The Beta 150 is specifically engineered for accurate and consistent sharpening of various tool types, including carbide and HSS tools. With its high-precision grinding wheel and adjustable supports, operators achieve optimal cutting edges for prolonged tool lifespan and enhanced job performance.

Durable Construction and Ease of Use

Built from industrial-grade steel and alloy, the Beta 150 is designed to last in demanding workshop environments. Its manual control and intuitive lever system ensure straightforward operation, making it accessible even for users with basic technical skills.

Integrated Coolant System for Extended Tool Life

Equipped with a coolant tank and pump, this tool sharpening machine maintains optimal grinding temperatures and minimizes tool wear. The coolant system prevents overheating, ensuring consistent sharpening quality and safer operation.

FAQ's of La Parora Italy Tool Sharpening Machine:

Q: How do I operate the La Parora Beta 150 Tool Sharpening Machine?

A: The Beta 150 operates manually using a lever/feed mechanism. You position your tool securely in the adjustable support, set your desired grinding parameters, and use the manual feed to start the sharpening process. The included coolant system helps keep the grinding wheel and tool cool during operation.Q: What types of tools can be sharpened with this machine?

A: This machine is designed for sharpening a wide range of standard tooling, including both carbide and high-speed steel (HSS) tools, thanks to its precision grinding wheel and robust construction.Q: When should I use the coolant system included with the Beta 150?

A: The coolant system should be engaged whenever you are sharpening tools, especially carbide or HSS, to prevent overheating. It helps extend the life of both the grinding wheel and the tools by maintaining optimal temperatures during sharpening.Q: Where is the La Parora Beta 150 typically used?

A: Commonly found in industrial workshops, tool rooms, and manufacturing plants, the Beta 150 is favored by exporters, importers, manufacturers, suppliers, and traders requiring high-precision tool maintenance.Q: What is the process for changing or maintaining the grinding wheel?

A: To change or maintain the grinding wheel, ensure the machine is switched off and unplugged, then safely remove the current wheel following the manufacturer's guidelines. Inspect for wear, replace if necessary, and securely mount the new wheel before restarting.Q: What are the key benefits of using the Beta 150 tool sharpening machine?

A: Key benefits include high sharpening precision, compatibility with a variety of tool materials, efficient cooling, robust construction, and ease of use, all contributing to improved productivity and reduced tooling costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Tool & Cutter Grinder Category

Felisatti Tool and Cutter Grinder

Price 1000 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Tilting Grinding Head, Rotatable Table, Adjustable Tool Holder

Processing Type : Grinding and Sharpening

Machine Type : BenchTop Tool & Cutter Grinder

Operate Method : Manual

Breda AFP50 Drill Grinding Machine

Price 2000 USD ($)

Minimum Order Quantity : 1 Piece

Features : Robust Construction, Precise Angle Adjustment, Suitable for HeavyDuty and Workshop Use

Processing Type : Drill Bit Grinding and Resharpening

Machine Type : Drill Grinding Machine

Operate Method : Manual and SemiAutomatic

TOS Universal Tool Cutter Grinder

Price 4000 USD ($)

Minimum Order Quantity : 1 Piece

Features : Includes diverse attachments and tools

Processing Type : Grinding, Sharpening, and Reconditioning

Machine Type : Universal Tool Cutter Grinder

Operate Method : Manual, with precise handwheels and controls

Helios Tool and Cutter Grinder

Price 2500 USD ($)

Minimum Order Quantity : 1 Piece

Features : Compact design versatile tool grinding capabilities

Processing Type : Tool resharpening

Machine Type : Helios Tool and Cutter Grinder

Operate Method : Manual

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry