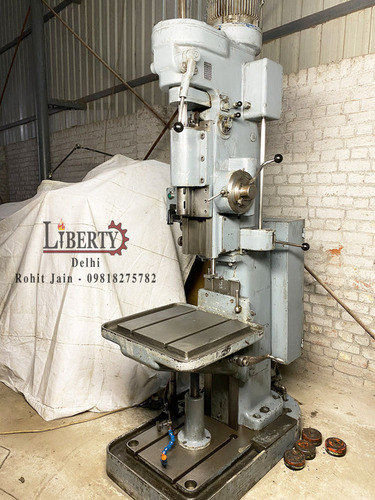

Caber 38 mm All Geared Pillar Drilling Machine

Price 22500 INR/ Piece

Caber 38 mm All Geared Pillar Drilling Machine Specification

- Machine Type

- All Geared Pillar Drill

- Diameter

- 38 mm (max drilling capacity)

- Features

- All-geared drive, robust construction, easy operation

- Motor Power

- 2 HP

- Cutting Area

- 38 mm (max drilling)

- Noise Level

- Low

- Table Size

- 420 mm diameter (approx.)

- Frequency

- 50 Hz

- Spindle Speed

- 702000 rpm (variable gears)

- Condition

- New

- Dimension (L*W*H)

- 1100 x 570 x 2050 mm

- Product Type

- Pillar Drilling Machine

- Material

- Cast Iron and Steel

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- CNC Or Not

- No

- Control System

- Manual

- Voltage

- 415 V

- Power

- 2.2 kW

- Power Source

- Electric

- Weight (kg)

- Approx. 600 kg

- Capacity

- 38 mm drilling

- Color

- Green

- Usage & Applications

- Industrial, workshop drilling, fabrication, production drilling

- Coolant System

- Provided

- Base Size

- 700 x 480 mm

- Maximum Distance Spindle to Base

- 1100 mm

- Maximum Distance Spindle to Table

- 720 mm

- Spindle Taper

- MT-4

- Chuck Capacity

- 13 mm to 20 mm

- Column Diameter

- 120 mm

- Spindle Travel

- 200 mm

- V-Belt Drive

- No (All Geared)

- Number of Spindle Speeds

- 8 to 12 Steps

- Distance from Spindle to Column

- 320 mm

Caber 38 mm All Geared Pillar Drilling Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Main Domestic Market

- All India

About Caber 38 mm All Geared Pillar Drilling Machine

Make - Caber (Italy)

Model - Mod. 58

Drilling Capacity - 38 mm

Spindle Diameter - 70 mm

Spindle Feed Travel - 195 mm

Spindle Taper - MT 4

Spindle Speeds - 60 rpm to 1000 rpm

Spindle Feed Rates - 0.06 mm/rev to 0.30 mm/rev

Table Size - 395 mm x 435 mm

Max. Height between Base Clamping Surface to Spindle - 1140 mm

- Table can be moved Up/Down and can also be Rotated.

- Machine is in excellent working condition.

Video of The Machine -

Precision Engineering for Reliable Performance

This pillar drilling machines all-geared mechanism provides superior accuracy and consistent torque across multiple spindle speeds. The robust construction and high-quality materials guarantee durability while supporting heavy-duty tasks over prolonged periods, making it a strong investment for industrial workshops.

Flexible Drilling Capacity and User-Friendly Operation

With a drilling capacity of up to 38 mm and adjustable spindle speeds from 70 to 2000 rpm, operators can efficiently handle various materials and tasks. The semi-automatic, manual control offers straightforward operation and quick setup, minimizing downtime in busy work environments.

Industrial-Grade Solutions for Multiple Applications

Engineered for fabrication, production drilling, and general industrial use, the Caber pillar drill machine is suitable for exporters, importers, manufacturers, and suppliers. Its low noise level and integral coolant system ensure a comfortable and safe working environment.

FAQs of Caber 38 mm All Geared Pillar Drilling Machine:

Q: How does the all-geared drive enhance the performance of the Caber 38 mm drilling machine?

A: The all-geared drive ensures smooth power transmission, consistent spindle speed, and reliable torque while reducing maintenance compared to belt-driven systems. This results in enhanced precision, stable operation, and longer machine life in demanding industrial settings.Q: What materials can be drilled with the Caber 38 mm pillar drill machine?

A: This machine is constructed with cast iron and steel, allowing it to drill through various materials including metals, alloys, and composite materials, with a maximum capacity of 38 mm diameter per hole.Q: Where is this drilling machine typically used?

A: The Caber 38 mm all geared pillar drilling machine is widely used in industrial workshops, fabrication units, and production facilities where precise, heavy-duty drilling is required.Q: What is the process for changing spindle speeds on this machine?

A: To adjust the spindle speed, operators use the gear selectors integrated into the machines mechanism. With 8 to 12 speed steps available, users can easily set the optimal RPM for each material and drilling requirement without the need for belt changes.Q: When should the coolant system be used during drilling operations?

A: The coolant system should be activated during extended or high-speed drilling tasks, especially when working with tough metals, to prevent overheating, prolong tool life, and improve drilling quality.Q: What benefits does the manual, semi-automatic control offer?

A: Manual, semi-automatic controls provide operators with direct command over the drilling process, enabling quicker adjustments, greater accuracy, and enhanced safety during operation.Q: Is this machine suitable for computer-controlled or CNC applications?

A: No, the Caber 38 mm pillar drilling machine is not designed for CNC or computerized automation. It operates manually with semi-automatic features, primarily supporting hands-on industrial tasks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pillar Drilling Machine Category

Fiat FM50 Pillar Drilling Machine

Automatic Grade : Manual

Machine Type : Pillar Drilling Machine

Usage & Applications : Drilling operations

Features : High precision drilling sturdy construction

Color : Grey

Power Source : AC

Temco Drilling & Tapping Machine

Automatic Grade : SemiAutomatic

Machine Type : Drilling & Tapping Machine

Usage & Applications : Drilling and Tapping Operations

Features : Efficient Drilling & Tapping

Color : Green

Power Source : AC

Industrie (Italy) Pillar Drilling Machine

Automatic Grade : Manual

Machine Type : Pillar Drilling Machine

Usage & Applications : Drilling in industrial environments

Features : Heavyduty construction with precision drilling

Color : Black

Power Source : Electric

Ambros Pillar Drilling Machine

Automatic Grade : Manual

Machine Type : Pillar Drilling Machine

Usage & Applications : Drilling operations

Features : Robust design round table for better grip

Color : White and Steel

Power Source : Electric

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry