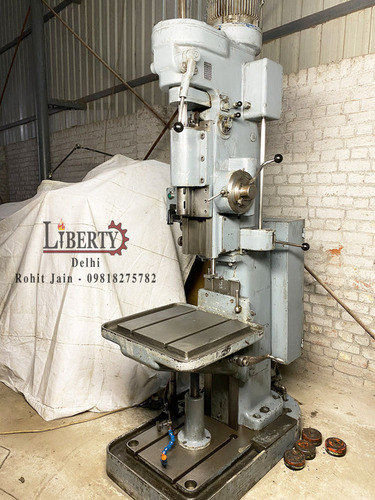

Temco Drilling & Tapping Machine

Temco Drilling & Tapping Machine Specification

- Condition

- Used

- Dimension (L*W*H)

- Standard Machine Dimensions

- Table Size

- Standard

- Features

- Efficient Drilling & Tapping

- Diameter

- Varies by Drill Bit

- Motor Power

- Standard Motor Size

- Frequency

- 50 Hz

- Machine Type

- Drilling & Tapping Machine

- Spindle Speed

- Adjustable

- Noise Level

- Standard

- Cutting Area

- Standard

- Product Type

- Industrial Machinery

- Material

- Industrial Grade Metal

- Automatic Grade

- Semi-Automatic

- CNC Or Not

- Not CNC

- Control System

- Manual

- Voltage

- 220V

- Power

- Electric

- Power Source

- AC

- Weight (kg)

- Varies by Model

- Capacity

- Varies by Drill Bit Size

- Color

- Green

- Usage & Applications

- Drilling and Tapping Operations

About Temco Drilling & Tapping Machine

We are an eminent name in the market as a leading manufacturer and supplier of high performing Drilling & Tapping Machine. This machine is highly praised due to its sturdy design and excellent performance. Manufactured using superior quality materials, this machine are offered to the clients as per their detailed specifications. Before dispatching, this is stringently tested for mechanical, chemical and hardness features and to ensure flawlessness. Further, it is available in different models to meet the desired requirements of our clients. Clients can avail this Drilling & Tapping Machine from us at industry-leading prices.

Features:

- Noise-free operations

- Robust construction

- Low maintenance

Robust Design for Industrial Use

Constructed with high-quality industrial grade metal, the Temco Drilling & Tapping Machine offers durability and long-lasting performance in demanding factory environments. Its green finish not only represents Temcos identity but also provides added protection against wear and corrosion, ensuring sustained operational reliability and minimal maintenance requirements.

Efficient Drilling & Tapping Performance

Optimized for both drilling and tapping, this machine features adjustable spindle speeds and can accommodate various drill bit diameters and cutting areas. Its efficient electric motor and semi-automatic operation streamline production processes, enabling users to handle multiple tasks with enhanced precision and reduced manual effort.

FAQs of Temco Drilling & Tapping Machine:

Q: How do I operate the Temco Drilling & Tapping Machine?

A: The machine is manually controlled, allowing the operator to adjust spindle speed and bit diameter as needed. The process involves setting up the workpiece on the standard size table, selecting the appropriate drill bit, adjusting the spindle speed, and using the control levers to perform drilling and tapping operations.Q: What materials can this machine handle for drilling and tapping?

A: Thanks to its industrial grade metal construction and efficient motor, the Temco machine is suitable for processing a range of metals and alloys commonly found in industrial applications. Drill bit size and spindle speed should be adjusted according to material type and thickness for optimal results.Q: When is this machine most commonly used in industrial settings?

A: This machine is typically employed in manufacturing and fabrication facilities for repetitive drilling and tapping tasks. Its semi-automatic, manual control system is ideal for batch production, maintenance work, and other applications where flexibility and operator oversight are needed.Q: Where can I purchase or import the Temco Drilling & Tapping Machine in India?

A: Temcos machines are available through a network of exporters, importers, manufacturers, suppliers, and traders across India. For specific procurement or partnership inquiries, you should contact authorized dealers or the main distributor in your industrial region.Q: What is the process to change drill bits and adjust spindle speed?

A: To replace drill bits, simply loosen the spindle chuck, insert the correct bit, and securely tighten it. Spindle speed can be modified using the provided manual controls, allowing you to tailor the speed based on your cutting needs and material specifications.Q: How does the machine benefit industrial production lines?

A: The Temco Drilling & Tapping Machine enhances productivity by enabling precise and efficient operations. Its adjustable features and robust design reduce downtime, while the semi-automatic format allows skilled operators to maintain flexibility and control throughout various production cycles.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pillar Drilling Machine Category

Caber 38 mm All Geared Pillar Drilling Machine

Price 22500 INR / Piece

Minimum Order Quantity : 1 Piece

CNC Or Not : Other, No

Machine Type : All Geared Pillar Drill

Automatic Grade : SemiAutomatic

Material : Cast Iron and Steel

Fiat FM50 Pillar Drilling Machine

Price 22500 INR / Piece

Minimum Order Quantity : 1 Piece

CNC Or Not : Other, Not CNC

Machine Type : Pillar Drilling Machine

Automatic Grade : Manual

Material : Metal

Ambros Pillar Drilling Machine

CNC Or Not : Not CNC, Other

Machine Type : Pillar Drilling Machine

Automatic Grade : Manual

Material : Steel

Industrie (Italy) Pillar Drilling Machine

CNC Or Not : Not CNC, Other

Machine Type : Pillar Drilling Machine

Automatic Grade : Manual

Material : Metal

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry