Cuoghi APE Tool Sharpening Machine

Price 25000 INR/ Piece

Cuoghi APE Tool Sharpening Machine Specification

- Cutting Force

- Manual/Adjustable

- Hardness

- Suitable for HSS, Carbide

- Tool Type

- Drill & End Mill Sharpening

- Operation Type

- Semi-Automatic

- Drill Bits Types

- Twist Drills, Step Drills, End Mills, Reamers, Countersinks, and Taps

- Material

- Industrial grade cast iron and steel

- Cutting Capacity

- 2 30 mm

- Shape

- Rectangular base with adjustable tool holder

- Cutting Accuracy

- High precision, micrometric adjustment

- Cutting Speed

- Depends on installed grinding wheel and driller

- Features

- Universal Grinding, Easy Adjustment, Compact Size, Durable Construction

- Operate Method

- Manual lever/feed

- Machine Type

- Tool Sharpening Machine

- Cutter Type

- Single & Multiple Flute Cutters

- Diameter

- 2 mm to 30 mm

- Processing Type

- Sharpening / Grinding

- Spindle Speed

- 2800 rpm

- Application

- Workshop, Maintenance, Production Line

- Weight

- Approx. 105 kg

- Motor Power

- 0.37 kW (approx.)

- Power Supply

- Three-phase 400V / 50Hz (or as required)

- Dimension (LxWxH)

- Approx. 740 mm x 660 mm x 620 mm

- Packing Type

- Wooden box

- Grinding Wheel Diameter

- 100 mm 125 mm

- Coolant System

- Integral coolant tank & pump (depending on configuration)

- Maximum Sharpening Length

- Up to 280 mm (depending on tool holder)

- Adjustment Precision

- Micro-metric adjustment for angle/length

Cuoghi APE Tool Sharpening Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Main Domestic Market

- All India

About Cuoghi APE Tool Sharpening Machine

Make - Cuoghi (Italy)

Model - APE

Diameter Range - 2 mm to 40 mm

Max. Grinding Wheel Diameter - 200 mm

Max. Grinding Wheel Width - 32 mm

Wheel Speed - 2800 rpm

Chuck Diameter - 130 mm (6-jaw type)

- Complete with spare Cams, many spare wheels, Wheel Flange etc.

- Machine is in very excellent working condition.

Video of The Machine -

Precision Re-Sharpening for Diverse Tools

Designed for versatility, the Cuoghi APE Tool Sharpening Machine accommodates a range of drill bits and cutters, including twist drills, step drills, end mills, reamers, countersinks, and taps. Its micro-metric adjustment system enables precise regrinding, preserving tool geometry and sharpness, while the adjustable tool holder ensures compatibility with both single and multiple flute cutters.

Robust Construction and Compact Design

Crafted from industrial-grade cast iron and steel, the machine is both durable and reliable in demanding environments. The rectangular base and compact dimensions (740 x 660 x 620 mm) make it suitable for installations in small workshops or production lines, while the wooden box packaging ensures safety during shipping and transport.

Integrated Coolant and Easy Operation

Depending on the model configuration, the Cuoghi APE features an integral coolant tank and pump, helping to maintain optimal grinding temperatures and prolong tool life. Semi-automatic operation with a manual lever/feed ensures intuitive handling, encouraging rapid and consistent sharpening with minimal training required.

FAQ's of Cuoghi APE Tool Sharpening Machine:

Q: How do you operate the Cuoghi APE Tool Sharpening Machine?

A: To use the Cuoghi APE, place the tool in the adjustable holder, secure it as per size and type, set the desired sharpening angle and length using the micro-metric adjustment, and start the machine. Manually guide the tool using the lever/feed while the grinding wheel sharpens the cutting edge. The process is semi-automatic and intuitive, suitable for operators with basic machine experience.Q: What types of tools can be sharpened with this machine?

A: This machine is capable of sharpening twist drills, step drills, end mills, reamers, countersinks, and taps. It supports both single and multiple flute cutters ranging from 2 mm to 30 mm in diameter and up to 280 mm in length, depending on the tool holder configuration.Q: When and where is the Cuoghi APE machine typically used?

A: The Cuoghi APE is commonly used in workshops, maintenance departments, and production lines that require frequent re-sharpening of cutting tools. Its robust construction and compact size make it ideal for both industrial and workshop environments where precision grinding is essential.Q: What are the benefits of using micro-metric adjustment?

A: Micro-metric adjustment allows for ultra-precise control over the sharpening angle and length, ensuring consistent results and optimal cutting performance. This high level of accuracy extends tool life and reduces production downtime due to tool replacement.Q: How does the integral coolant system contribute to the sharpening process?

A: The built-in coolant tank and pump (depending on configuration) assist in cooling the tool and grinding wheel during operation. This prevents overheating, reduces wear on both the tool and wheel, and helps achieve smoother finishes while maintaining dimensional accuracy.Q: What materials is the Cuoghi APE suitable for sharpening?

A: The machine can sharpen tools made from high-speed steel (HSS), carbide, as well as other durable materials commonly used in industrial applications. Its sturdy build and precise controls ensure reliable performance across a wide range of tool hardness.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Tool & Cutter Grinder Category

Avyac France Drills and End-Mills Grinding Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Features : High Precision, Rapid Tool Setup, Easy Changeover, Cooling System

Operation Type : Other, Manual or SemiAutomatic

Operate Method : HandOperated, Optional Motorized Feed

Machine Type : Universal Drill & EndMill Grinding Machine

Schutte Germany Hydraulic Universal Tool & Cutter Grinder

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Hydraulic Table Movement, Universal Head, 3Jaw Chuck, MultiAxis Wheelhead

Operation Type : Other, Hydraulic Automatic with Manual Adjustment

Operate Method : Hydraulic + Manual Controls

Machine Type : Hydraulic Universal Tool & Cutter Grinder

Bi Emme Single Lip Tool Cutter Grinder

Price 3000 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Adjustable Angles, VibrationFree Operation, Compact Design

Operation Type : Other, Manual / SemiAutomatic

Operate Method : Manual Adjustment with Rotating and Swiveling Head

Machine Type : Universal Tool Cutter Grinder

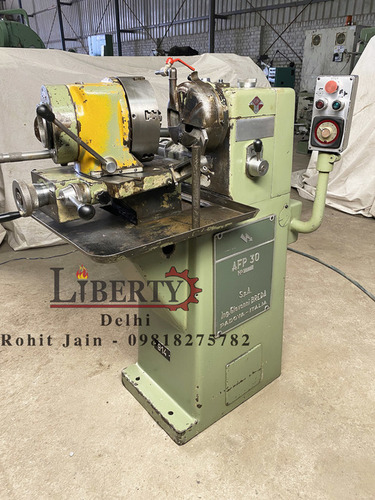

Breda AFP 30 Drill Grinding Machine

Price 10000 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Angle adjustable, Integrated coolant tray, Quick clamping system

Operation Type : Other, Electrical, Motordriven

Operate Method : Manual / Semiautomatic

Machine Type : Benchtop Drill Grinding Machine

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry