Cuoghi Italy APE-60 Tool Sharpening Machine

Price 100000.0 INR/ Piece

Cuoghi Italy APE-60 Tool Sharpening Machine Specification

- Cutter Type

- End mills and core drills

- Operate Method

- Manual/automatic via control panel

- Cutting Capacity

- Tools up to 320 mm length, diameter 3 mm to 60 mm

- Features

- High rigidity construction, micrometric settings, quick setup, multi-tool compatibility, Italian build quality

- Coating

- Uncoated

- Shape

- Rectangular base with mounted rotating spindle and adjustable holders

- Machine Type

- Universal tool and cutter sharpening machine

- Material

- Industrial-grade cast iron and steel construction

- Tool Type

- End mills, drills, step drills, taps, reamers, and other rotary tools

- Coating Type

- Uncoated (machine provides grinding, coating is tool-dependent)

- Drill Bits Types

- Standard, step, and twist drills

- Cutting Accuracy

- High precision (micrometric adjustment)

- Cutting Speed

- Variable, depending on tool type and material

- Operation Type

- Manual with semi-automatic functions

- Length

- Supports tools up to 320 mm

- Diameter

- Up to 60 mm (tool diameter)

- Processing Type

- Tool sharpening, grinding, and reconditioning

- Spindle Motor Power

- 1.25 kW

- Model

- APE-60

- Max Tool Length

- 320 mm

- Max Tool Diameter

- 60 mm

- Accuracy Adjustments

- Micrometric (0.01 mm scale)

- Net Weight

- 330 kg approx.

- Coolant System

- Integrated recirculating coolant system

- Spindle Speed

- 2800 rpm

- Voltage

- 380V / 3 phase / 50 Hz

- Grinding Wheel Size

- 125 mm to 150 mm

Cuoghi Italy APE-60 Tool Sharpening Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Main Domestic Market

- All India

About Cuoghi Italy APE-60 Tool Sharpening Machine

Make - Cuoghi (Italy)

Model - APE-60

Diameter Range - 3 mm to 60 mm

Min. & Max. Drill Angle - 40 degree to 180 degree

Grinding Wheel Size - Diameter 200 mm x 45 mm Width

Chuck Diameter - 160 mm (6-jaw type).

- Complete with Web-Thinning Attachment.

- Equipped with Wheel Dresser.

- Suitable for both Dry Grinding and for Wet Grinding applications.

- Complete with spare Cams & other accessories.

- Operating Manual & Electrical Drawing of the machine is available.

- Machine is in excellent working condition.

Video of The Machine -

Exceptional Precision and Versatility

The APE-60 model offers micrometric (0.01 mm scale) adjustments, enabling users to achieve high-precision sharpening. Its universal compatibility supports various rotary tools, including end mills, drills, taps, and reamers, making it suitable for export, import, manufacturing, and trading operations.

Reliable Italian Engineering and Construction

Manufactured in Italy with premium cast iron and steel, this machine provides lasting durability and stability during use. Its rectangular base and adjustable holders contribute to efficient tool setup and reliable machining, underscoring renowned Italian build quality.

User-Friendly Operation with Advanced Features

Offering manual and semi-automatic functions, the APE-60 enables operators to control sharpening processes via an intuitive control panel. The integrated coolant system ensures safe and smooth grinding, while quick setup and multi-tool capability help streamline workshop workflow.

FAQs of Cuoghi Italy APE-60 Tool Sharpening Machine:

Q: How do I operate the Cuoghi Italy APE-60 Tool Sharpening Machine?

A: This machine allows for both manual and semi-automatic operation modes. You can adjust settings and initiate sharpening through its user-friendly control panel, and the precise micrometric adjustments enable fine-tuning of tool dimensions for optimal results.Q: What types of tools can the APE-60 sharpen or recondition?

A: The APE-60 is engineered for sharpening and grinding rotary tools, including end mills, drills (standard, step, twist), taps, reamers, and core drills. Its adaptable design accommodates a tool diameter up to 60 mm and length up to 320 mm.Q: When should I use the APE-60 for tool maintenance?

A: Utilize the APE-60 whenever your tools show signs of wear, reduced cutting efficiency, or require high-precision edges for demanding jobs. Regular sharpening ensures enhanced tool life and maintains consistent machining performance.Q: Where is the APE-60 most effectively utilized?

A: The machine is best suited for workshops, manufacturing facilities, and tool rooms where rotary tool sharpening and reconditioning are routine. Its robust construction supports both small businesses and large-scale operations needing reliable performance.Q: What is the process for sharpening a tool with this machine?

A: Begin by securely mounting the tool into the adjustable holders, select the appropriate grinding wheel (125-150 mm), set spindle speed and micrometric accuracy, and engage the coolant system. Operate manually or semi-automatically, using the control panel to fine-tune adjustments.Q: How does the integrated coolant system benefit sharpening operations?

A: The recirculating coolant system consistently cools the grinding wheel and tool surface, minimizing heat buildup, reducing wear, and preventing thermal damage, which results in smoother finishes and extended tool life.Q: What are the key benefits of choosing the APE-60 tool sharpening machine?

A: Key advantages include high-precision micrometric adjustments, multi-tool compatibility, durable Italian construction, efficient coolant management, and flexible manual/semi-automatic operationall contributing to improved productivity and superior sharpening outcomes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Tool & Cutter Grinder Category

Jones Shipman 310T Universal Tool Cutter Grinder Machine

Price 45000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Others, Heavy cast iron body, steel and iron components

Cutting Speed : Infinitely variable via spindle (adjustable)

Tool Type : Universal Tool & Cutter

Hardness : Adaptable via grinding wheel (dependent on application)

Brierley ZB32 Universal Precision Drill and End Mill Grinder

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Others, Steel Body Construction, Cast Base

Cutting Speed : 3000 RPM (Motor Speed)

Tool Type : Precision Grinder

Hardness : Supports High Hardness Tool Steel

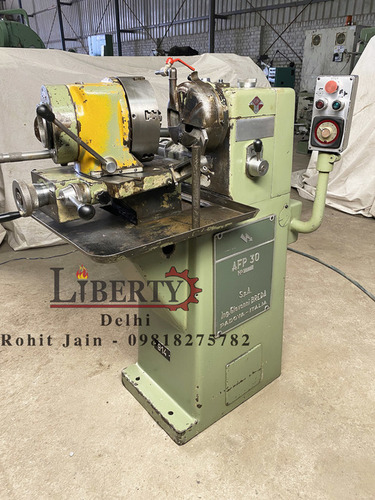

Breda AFP 30 Drill Grinding Machine

Price 10000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Others, Cast Iron body with steel guideways

Cutting Speed : Variable, up to 2300 RPM

Tool Type : Drill Bit Sharpener/Grinding Tool

Hardness : Suitable for HSS and Carbide Tools

TOS BN101 Universal Tool and Cutter Grinder

Price 21000 INR

Minimum Order Quantity : 1 Piece

Material : Others, Cast iron body with steel working parts

Cutting Speed : Adjustable, up to 2850 rpm motor speed

Tool Type : Universal tool & cutter grinder

Hardness : Hardened steel parts, 60 HRC (main spindle)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry