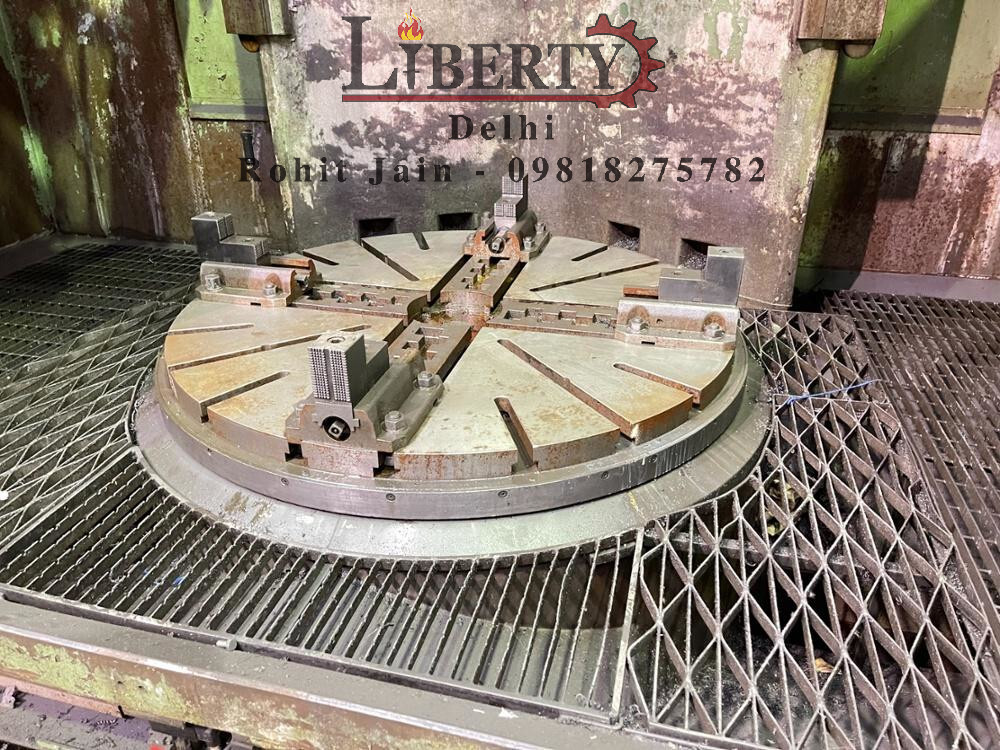

Dorries 2100 mm Swing Ram-type CNC VTL Machine

Price 65000 INR/ Piece

Dorries 2100 mm Swing Ram-type CNC VTL Machine Specification

- Model No

- Dorries 2100

- Lubricating System

- Automatic centralized lubrication

- Cooling System

- Integrated coolant system

- Power Rating

- 55 kW

- Frame Type

- Heavy fabricated structure

- Frequency

- 50 Hz

- Drive

- CNC Servo Motor Drive

- Motor Power

- 55 kW

- Features

- Ram-type construction, High rigidity, Large swing capacity

- Connectivity Options

- Ethernet, USB

- Voltage

- 400 V

- Control System

- Siemens/Fanuc CNC

- Noise Level

- <75 dB

- Accuracy

- 0.02 mm

- Machine Type

- CNC Vertical Lathe

- Operating Temperature

- 5C - 45C

- Product Type

- Vertical Turning Lathe (VTL)

- Technology

- Ram-type CNC

- Power Source

- Electric

- Operating Type

- Fully Automatic

- Power

- Main Drive 55 kW

- Surface Treatment

- Painted, Powder Coated

- Dimension (L*W*H)

- Approx. 4800 mm x 3600 mm x 4800 mm

- Weight (kg)

- Approximately 28,000 kg

- Color

- Industrial Grey/Blue

- Usage & Applications

- Heavy-duty turning and facing of large round components, industrial parts manufacturing

- Chuck Type

- 4-jaw Manual/Automatic

- Tool Magazine Capacity

- Up to 10 tools

- Installation Requirement

- Reinforced concrete foundation

- Service Support

- Remote and On-site available

- Applicable Standards

- CE, DIN

- Coolant Tank Capacity

- 400 liters

- Positioning Accuracy

- 0.02 mm

- Repeatability

- 0.01 mm

- Swing Diameter

- 2100 mm

- Electrical Protection

- Overload & Short Circuit Safeguards

- WorkingSpeed

- Variable, programmable up to 250 RPM

- Table Diameter

- 1800 mm

- Hydraulic System

- Available for clamping

- Operator Interface

- Touchscreen Display

- Maximum Turning Height

- 1600 mm

- Spindle Speed Range

- 10 250 RPM

- Main Spindle Taper

- ISO 50

- Axis Configuration

- 2-axis (X, Z)

- Rapid Traverse Rate

- 10,000 mm/min

- Spindle Type

- Ram-type

- Ram Stroke

- Up to 1000 mm

- Ambient Conditions

- Dust & temperature-protected enclosure

- Safety Features

- Emergency Stop, Door Interlocks

- Maximum Workpiece Weight

- 10,000 kg

Dorries 2100 mm Swing Ram-type CNC VTL Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Main Domestic Market

- All India

About Dorries 2100 mm Swing Ram-type CNC VTL Machine

Make - Dorries (Germany)

Model - VCE 2000 / 140

Table Diameter - 1400 mm

Max. Swing Diameter - 2100 mm

Max. Height under Crossrail to Table - 1900 mm

Ram Travel - 1500 mm

CNC Control - Fagor 8055T

Automatic Tool Changer - 12 Station ATC

Table Speed Range - 2 rpm to 224 rpm

RAM Size - 240 mm x 240 mm

Rapid Traverse Speeds - 6 m/min

Weight of the Machine - 41 Tons (Approx.)

- Retrofitted in 2008 with Fagor CNC Controller

- Cross-Rail, Slides & Ram are completely scractless.

- Operating Manuals, Electrical Drawings, Service Manuals etc are available.

- Machine is in excellent working condition.

High Precision and Efficiency

Engineered for outstanding precision, the Dorries 2100 Ram-type CNC VTL delivers tight tolerances with repeatability of 0.01 mm. Variable speed programming, automatic tool change, and a robust CNC control system ensure efficiency in high-volume, demanding jobs. The two-axis configuration (X, Z) allows precise heavy-duty turning and facing, ideal for large industrial components.

Robust Build and Safety Features

The heavy-fabricated structure and ram-type spindle offer high rigidity essential for machining large workpieces up to 10,000 kg. Comprehensive safety features include emergency stops, door interlocks, and advanced electrical safeguarding. The machine enclosure is protected against dust and temperature variations, ensuring a reliable and safe working environment.

Versatile Operations and User-friendly Interface

A touchscreen display powered by Siemens or Fanuc CNC control enhances operational convenience. The 10-tool magazine, rapid traverse rate of 10,000 mm/min, and automatic lubrication system collectively simplify and expedite machining processes. Connectivity via Ethernet and USB allows seamless data transfer and remote monitoring for modern industrial workflows.

FAQs of Dorries 2100 mm Swing Ram-type CNC VTL Machine:

Q: How is the Dorries 2100 mm Swing Ram-type CNC VTL machine installed and what are the foundation requirements?

A: The Dorries 2100 mm CNC VTL requires installation on a reinforced concrete foundation to support its approximate weight of 28,000 kg and ensure stability during heavy-duty operations. This reinforced base minimizes vibrations and inaccuracies, contributing to long-term machine performance. Professional installation is recommended for optimal setup and calibration.Q: What types of workpieces and industries benefit most from this VTL machine?

A: This CNC VTL is ideal for heavy industries that process large, round componentssuch as energy, shipbuilding, machinery manufacturing, and aerospace sectors. Its capacity to handle workpieces up to 10,000 kg and 2100 mm swing diameter makes it particularly suitable for producing industrial parts, flanges, rings, and pressure vessel components.Q: When should the ram and spindle settings be adjusted, and how is this managed?

A: Ram and spindle settingssuch as speed and strokeshould be adjusted based on the material, workpiece size, and required surface finish. Adjustments are made directly from the CNC touchscreen interface, where operators can program spindle speeds up to 250 RPM and set ram strokes, ensuring optimal machining performance for each job.Q: Where does the machine handle cooling, lubrication, and safety operations during turning processes?

A: Integrated within the machine structure, the 400-liter coolant tank and automatic centralized lubrication system manage both cooling and lubrication, supporting consistent cutting and tool longevity. Comprehensive safety is ensured via emergency stop buttons, door interlocks, overload, and short circuit protection circuits throughout the operational area.Q: What is the typical process for changing tools and how does the tool magazine contribute to productivity?

A: Tool changes are performed automatically through the machines tool magazine, which accommodates up to 10 tools. Operators can pre-program tool changes via the control panel, minimizing downtime and increasing throughput during multi-step machining operations. This feature is pivotal for complex or batch production runs.Q: How does using a CNC VTL of this type improve operational efficiency and product quality compared to manual lathes?

A: The Dorries 2100 mm Ram-type CNC VTL offers precision automation, consistent repeatability (0.01 mm), and programmable control that manual lathes simply cannot match. This results in faster cycle times, minimal setup errors, efficient handling of large components, and higher quality, uniform output over extended production periods.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vertical Turning Lathe (VTL) Category

Doosan PUMA V400 Vertical Turning Center CNC VTL Machine

Price 100000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Features : HeavyDuty Cast Iron Bed, High Rigidity, Chip Conveyor, Enclosed Guarding

Usage & Applications : Precision turning of large cylindrical parts such as wheels, rings, flanges

Power Source : Other, Electric

Color : Standard Doosan Blue & White

Doosan PUMA V400 CNC Vertical Turning Lathe (CNC VTL) Machine

Price 100000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Rigid construction, high efficiency, large work capacity, compact footprint

Usage & Applications : Precision vertical turning and machining of cylindrical components

Power Source : Other, Electric

Color : White & Blue

Titan SC 22 Vertical Turning Lathe

Features : Sturdy construction, high rigidity, large table diameter, advanced drive system

Usage & Applications : Heavy duty turning operations, machining large cylindrical parts

Power Source : Other, Electric

Color : Blue & Grey

TOS SKJ 10 Vertical Turret Lathe

Price 1100 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Features : Vertical turret lathe robust frame suitable for heavyduty tasks

Usage & Applications : Heavy machining industrial applications

Power Source : Electric, Other

Color : Green

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry