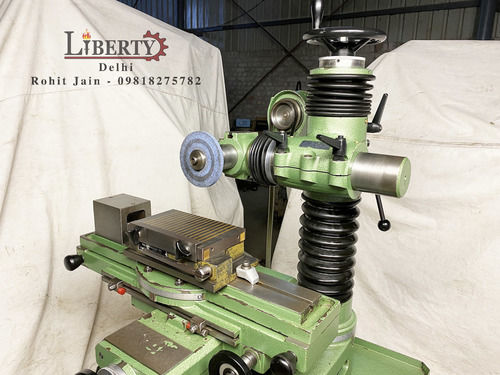

Jones & Shipman 310T Tool & Cutter Grinder

Price 2000 INR/ Piece

Jones & Shipman 310T Tool & Cutter Grinder Specification

- Cutting Force

- Manual, dependent on operator

- Tool Type

- Cutting Tools, Endmills, Drills

- Operate Method

- Manual with adjustable controls

- Operation Type

- Surface, cylindrical, and internal grinding

- Cutting Speed

- Variable, up to 2800 RPM spindle speed

- Shape

- Rectangular Base, with adjustable Table and Head

- Material

- Cast Iron Construction, steel guides

- Cutting Accuracy

- 0.005 mm

- Cutting Capacity

- To grind tools up to 250 mm

- Hardness

- High precision hardened steel components

- Machine Type

- Tool & Cutter Grinder

- Features

- Swing-over table, adjustable speed, coolant system

- Drill Bits Types

- Multiple (end mills, reamers, drills)

- Length

- Approx. machine length 1000 mm

- Cutter Type

- Universal, suitable for varied geometry

- Diameter

- Wheel diameter up to 200 mm

- Processing Type

- Tool Grinding, Cutter Resharpening

- Table Size

- 270 x 160 mm

- Year of Manufacture

- Various (classic model, specification-specific)

- Lubrication

- Manual lubrication points

- Table Movement

- Longitudinal (manual), transverse (manual)

- Max Tool Length

- Up to 250 mm

- Net Weight

- Approx. 500 kg

- Head Adjustment

- Tilt & swivel, vertical adjustment

- Safety Features

- Emergency stop switch, splash protection

- Spindle Motor Power

- 0.5 HP (approx. 0.37 kW)

- Electrical Requirements

- 3 Phase, 415V, 50Hz

- Coolant System

- Integrated with splash guard

- Dimensions (LxWxH)

- 1000 x 700 x 1300 mm

- Chuck Type

- Collet or standard mounting

- Supported Attachments

- Radius attachment, grinding wheel dresser

About Jones & Shipman 310T Tool & Cutter Grinder

Make - Jones & Shipman (England)

Model - 310T

Max. Swing Diameter on Cutter Head (Adjustable) - 330 mm

Max. Swing Diameter on Centers - 200 mm

Length b/w Tailstock Centers - 480 mm

Longitudinal Travel - 445 mm

Cross Travel - 187 mm

Vertical Travel - 200 mm

Clamping Surface - 750 mm x 110 mm

Grinding Wheel Diameter - 150 mm

- Wheel-Head can be Rotated as well as Tilted.

- Machine is in excellent working condition.

Video link - https://youtu.be/LI7ln32mDgs

Versatile Grinding Precision

Engineered for flexibility, the Jones & Shipman 310T supports tool grinding, cutter resharpening, and intricate shaping processes. Its variable spindle speed and adjustable controls allow the handling of a broad range of tool geometries, making it ideal for surface, cylindrical, and internal grinding tasks.

Robust Construction & Safety

Built with a durable cast iron base and high-precision steel guides, this grinder is designed to endure intensive workshop use. Enhanced safety measures, including an emergency stop and splash guards, support secure operation and protect users during demanding jobs.

Integrated Coolant & Attachments

The machine is equipped with an integrated coolant system featuring a splash guard to maintain optimal grinding temperatures. It also supports essential attachments such as a radius device and wheel dresser, expanding its capability to work on specialized tool profiles.

FAQs of Jones & Shipman 310T Tool & Cutter Grinder:

Q: How do you adjust the grinding head for different tool geometries with the Jones & Shipman 310T?

A: The grinding head on the 310T can be easily adjusted for tilt, swivel, and vertical movement. This enables operators to accommodate a wide variety of tool shapes and resharpen different kinds of cutting tools accurately. Controls are designed for manual, precise setting.Q: What are the main applications and supported tool types on this grinder?

A: The Jones & Shipman 310T is suited for sharpening and grinding cutting tools such as end mills, drills, and reamers. Its universal mounting and adjustable table make it efficient for processing tools up to 250 mm in length and up to 250 mm, supporting both standard and special tool geometries.Q: When is it recommended to use the integrated coolant system?

A: The integrated coolant system should be used during all grinding and resharpening processes to prevent overheating, maintain workpiece integrity, and prolong grinding wheel life. The splash guard minimizes mess and enhances operational safety.Q: Where can this tool & cutter grinder be installed for optimal performance?

A: Install the grinder on a stable, level floor with accessible three-phase 415V/50Hz electricity. Its suitable for machine shops, tool rooms, and manufacturing facilities where precision sharpening and grinding are required.Q: What is the process for maintaining and lubricating the 310T grinder?

A: Routine maintenance includes cleaning the machine after use and applying lubricant at all manual lubrication points as indicated in the user manual. Regular checks ensure prolonged performance and machinery accuracy.Q: How does the manual operation influence cutting accuracy and capacity?

A: Manual controls allow finely tuned adjustments for each grinding operation, enabling operators to achieve the specified accuracy of 0.005 mm. Although speed is operator dependent, this manual approach offers excellent control for delicate and complex tool sharpening tasks.Q: What are the key benefits of choosing the Jones & Shipman 310T Tool & Cutter Grinder?

A: This classic, high-precision grinder delivers reliable performance, versatility across tool types, and includes safety and cooling features for professional environments. Its sturdy build and variety of attachments make it a valued addition to any workshop focused on quality tool conditioning.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Tool & Cutter Grinder Category

Avyac France Drills and End-Mills Grinding Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Features : High Precision, Rapid Tool Setup, Easy Changeover, Cooling System

Processing Type : Universal Grinding, Sharpening, Reconditioning

Cutter Type : MultiFlute Cutter, SingleFlute Cutter

Tool Type : Drills, End Mills, Related Cutting Tools

Bi Emme Single Lip Tool Cutter Grinder

Price 3000 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Adjustable Angles, VibrationFree Operation, Compact Design

Processing Type : Tool Grinding / Resharpening

Cutter Type : Single Lip Tool Cutter

Tool Type : Single Lip, End Mills, Engraving/Profiling Cutters

La Parora Italy Tool Sharpening Machine

Price 100000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Coolant tank and pump included, robust construction, adjustable supports, made in Italy

Processing Type : Grinding / Sharpening

Cutter Type : Tool Sharpener Wheel

Tool Type : Tool Sharpening Machine

CG Standard Universal Tool and Cutter Grinder

Price 18000 INR

Minimum Order Quantity : 1 Piece

Features : Swiveling head, adjustable tailstock, robust cast iron body, precision slides, easy wheel replacement

Processing Type : Grinding and Resharpening

Cutter Type : HSS & Carbide Tools

Tool Type : Universal Tool Grinder

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry