Jotes SAB-100W Vertical Rotary Surface Grinder

Price 100000 INR/ Piece

Jotes SAB-100W Vertical Rotary Surface Grinder Specification

- Rotation

- Rotary table

- Model

- SAB-100W

- Product Type

- Vertical Rotary Surface Grinder

- General Use

- Rotary Surface Grinding

- Material

- Cast Iron body, Steel components

- Type

- Rotary Surface Grinder

- Capacity

- Large-scale industrial

- Weight (kg)

- Approx. 7000 kg

- Computerized

- No

- Automatic

- No

- CNC Or Not

- No (Manual Machine)

- Control System

- Manual

- Table Size

- 1000 mm

- Table Slide Way

- Hydraulic

- Magnetic Chuck Size

- 1000 mm

- Grinding Wheel Size

- 400 mm

- Grinding Wheel Speed

- 1450 rpm

- Grinding Length

- 1000 mm

- Floor Space

- 3000 x 3200 mm

- Fuel Tank Capacity

- 60 Litres

- Spindle Speed

- 1450 rpm

- Power

- 15 kW

- Voltage

- 400 V

- Dimension (L*W*H)

- 3000 x 3200 x 2200 mm

- Feature

- Heavy duty, robust construction, high precision grinding

- Color

- Grey

- Table Load Capacity

- Up to 1500 kg

- After Sales Service

- Provided

- Packing Type

- Standard Export Packing

- Year of Manufacture

- Refer To Manufacturer

- Surface Finish Accuracy

- Up to 0.002 mm

- Coolant System

- Integrated

- Noise Level

- Low (Industry Standard)

- Max. Grinding Height

- 350 mm

- Lubrication Type

- Centralized automatic lubrication

- Operator Safety Features

- Emergency stop, safety covers

- Installation Service

- Available on request

- Working Speed

- Variable (Depends on operation)

Jotes SAB-100W Vertical Rotary Surface Grinder Trade Information

- Minimum Order Quantity

- 1 Piece

- Main Domestic Market

- All India

About Jotes SAB-100W Vertical Rotary Surface Grinder

Make - Jotes (Poland)

Model - SAB 100W

Magnetic Table Diameter - 1000 mm

Max. Height of Job - 390 mm

Grinding Wheel Diameter - 530 mm

Table Rotation Speeds - 5 rpm to 30 rpm

Grinding Wheel Type - Segmented

No. of Segments in Grinding Wheel - 10 pcs.

Grinding Wheel Spindle Motor - 30 kW

Least Count of Vertical Travels - 5 Microns (0.005 mm)

Table Forward & Backward Travels - 550 mm

Max. Swing Diameter - 1100 mm

Weight - 8 Tons (Approximately)

- Motorised Rapid Vertical Travel of Wheel-Head.

- Motorised Rapid Forward & Backward Movement of Table.

- Feature of Automatic Depth Adjustment "Auto-Cut".

- Equipped with Wheel Dressing Attachment.

- With Magnetic Coolant Filtration Unit, Coolant Pump & Coolant Tank.

- Electrical Drawings of the Machine are available.

- Machine is in excellent working condition.

Video of The Machine -

Reliable High-Precision Grinding

The SAB-100W delivers exceptional surface finish accuracy of up to 0.002 mm, supported by a robust, heavy-duty design. Its manual control system offers flexibility and ease of operation, while integrated hydraulic table movement and centralized lubrication ensure consistent performance.

Operator-Centric Safety and Design

Operator safety is at the forefront, featuring emergency stop functions and full safety covers. The machine emits minimal noise, ensuring a comfortable working environment, and all controls are ergonomically positioned for efficient manual operation. Ease of maintenance is ensured via centralized lubrication and robust construction.

Comprehensive Service and Support

Installation is available upon request, and after-sales service is provided to ensure long-lasting performance. The grinder is packed in standard export packaging to ensure safe delivery, with export expertise from Poland that assures global standards are met throughout the process.

FAQ's of Jotes SAB-100W Vertical Rotary Surface Grinder:

Q: How does the Jotes SAB-100W ensure precise surface grinding results?

A: The SAB-100W achieves high grinding precision up to 0.002 mm thanks to its stable cast iron body, hydraulic table slide way, and centralized automatic lubrication. These features collectively minimize vibration and ensure uniform grinding across large surfaces.Q: What are the main operator safety features included with this grinder?

A: This model is equipped with operator safeguards such as an emergency stop button, secure safety covers, and low-noise operation levels. These elements help create a safe and comfortable working environment while reducing the risk of accidents.Q: When is after-sales service and installation support available?

A: After-sales service is provided for all units to ensure optimal performance throughout the machine's lifespan. Installation services are available on request, allowing clients to benefit from professional setup and commissioning.Q: Where can the SAB-100W be installed, and what are the space requirements?

A: The SAB-100W can be installed in any large industrial facility with adequate power supply and a level floor area. It requires a minimum floor space of 3000 x 3200 mm and suitability for handling its approximate 7000 kg weight.Q: What is the process for using the integrated coolant and lubrication systems?

A: The machine features an integrated coolant system to maintain optimal grinding temperatures and extend tool life. Centralized automatic lubrication ensures all critical moving components are consistently lubricated, reducing maintenance needs and enhancing operational longevity.Q: What are the main benefits of choosing this manual rotary surface grinder over computerized alternatives?

A: Opting for the manual SAB-100W provides operators with direct control over grinding operations, making it suitable for custom, specialized, or low-volume tasks. Its solid construction, large capacity, and proven reliability make it ideal for heavy-duty, precision applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Surface Grinder Category

SIT France 130 mm x 300 mm Surface Grinder

Price 20000 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic : No

Computerized : No

Feature : Other, Precision Ground, Easy Operation, Robust Construction

CNC Or Not : Other, Not CNC

Jones and Shipman 540P Surface Grinder Machine

Price 37500 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic : Yes

Computerized : No

Feature : Other, High Precision; Robust Structure

CNC Or Not : Other, Not CNC

TOS BPV 300/1 Vertical Surface Grinder

Price 3300 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Automatic : No

Computerized : No

Feature : Other, Vertical Surface Grinding

CNC Or Not : Other, No

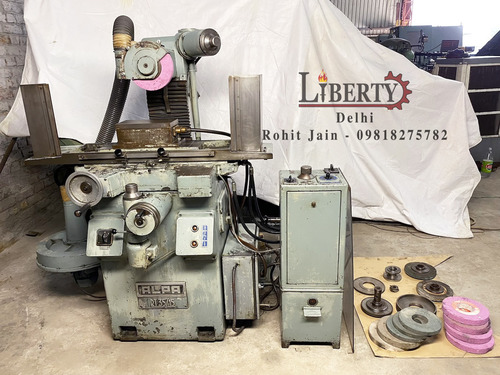

Alpa Precision Surface Grinder

Price 2500 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Automatic : No

Computerized : No

Feature : Precision Surface Grinding, Other

CNC Or Not : Other, Not CNC

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry