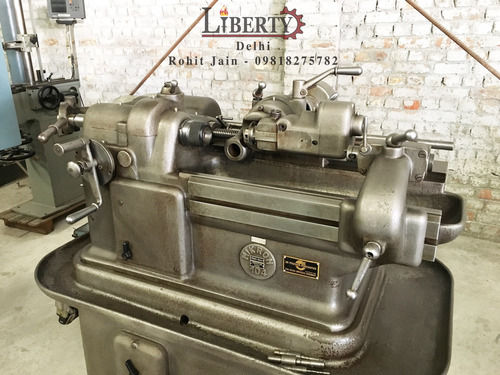

Lees Bradner Thread Milling Machine

Lees Bradner Thread Milling Machine Specification

- Model

- Lees Bradner

- Rotation

- Manual/Programmable lead rotation

- Product Type

- Thread Milling Machine

- General Use

- Industrial Thread Milling

- Material

- Cast Iron, Alloy Steel

- Type

- Horizontal

- Capacity

- Up to 36 length, up to 16 diameter

- Weight (kg)

- Approx. 2500 kg

- Computerized

- No

- Automatic

- No

- CNC Or Not

- Not CNC

- Control System

- Manual

- Table Size

- 675 mm x 255 mm

- Table Slide Way

- Box type

- Floor Space

- 1800 mm x 1100 mm approx.

- Spindle Speed

- Variable, up to 600 RPM

- Power

- 5 HP

- Voltage

- 415 V

- Dimension (L*W*H)

- 1800 mm x 1100 mm x 1500 mm (approx)

- Feature

- High Precision, Heavy Duty

- Color

- Green

- Spindle Bore

- 66 mm

- Max. Workpiece Length

- Up to 914 mm (36")

- Max. Thread Pitch

- Up to 12 TPI

- Main Drive

- Mechanical transmission

- Lead Screw Material

- Hardened Steel

- Maintenance

- Easy access to lubrication points

- Max. Thread Diameter

- 406 mm (16")

- Coolant System

- Built-in

- Gear Change

- Quick change gearbox

- Surface Finish

- Up to 1.5 micron Ra

- Working Speed

- Variable

- Chuck Type

- 3-Jaw manual chuck

- Machine Type

- Universal Thread Milling

- Thread Type Capability

- External & Internal

- Min. Thread Diameter

- 25 mm

- Safety Features

- Emergency stop, electrical interlocking

About Lees Bradner Thread Milling Machine

Make - Lees-Bradner (USA)

Model - HT 12x54

Max. Job Diameter - 305 mm (12")

Max. Length of Job - 1372 mm (54")

Spindle Bore - 152 mm (6")

Range of Cutter Head Rotation - 135 degree to -45 Degree

Max. Cutter Diameter - 165 mm (6.5")

Max. Swing Diameter over Bed-Ways - 580 mm (22")

Max. Module - 11.12 module (2.5 CP)

- With Rapid Longitudinal Travel of the Carriage.

- Complete with lots of Cutters, Change Gears, Index Plates etc.

- With lots of other accessories including mandrels etc.

- Machine is in excellent working condition.

Video link - https://youtu.be/JA_BK-UONwA

Versatile Threading Capabilities

Engineered for both internal and external threading, the Lees Bradner Thread Milling Machine accommodates a wide spectrum of thread diameters and pitches. With a minimum thread diameter of 25 mm and a maximum of 406 mm, users can efficiently machine diverse components. Its maximum thread pitch supports up to 12 TPI, making it suitable for heavy-duty threading operations in various industrial sectors.

Precision and Efficiency Combined

Delivering a superior surface finish of up to 1.5 micron Ra, this machine excels in producing high-quality threads. The quick-change gearbox and variable spindle speeds ensure operational flexibility, while the hardened steel lead screw and durable mechanical transmission provide consistent performance. Its heavy-duty cast iron frame minimizes vibrations, enhancing both accuracy and tool life.

Operability and Safety Assured

With a user-friendly manual control system and easily accessible lubrication points, operators benefit from straightforward usage and convenient maintenance. Safety has been prioritized with features like an emergency stop button and electrical interlocking, ensuring secure operation in demanding industrial environments. The built-in coolant system further supports extended machining by preventing overheating.

FAQs of Lees Bradner Thread Milling Machine:

Q: How is the Lees Bradner Thread Milling Machine operated?

A: The Lees Bradner Thread Milling Machine is manually operated, utilizing mechanical transmission and a 3-jaw manual chuck. Thread pitch and spindle speed adjustments are handled through the quick-change gearbox, while lead rotation can be set manually or using programmable options depending on the model.Q: What types and sizes of threads can this machine produce?

A: This machine is capable of cutting both external and internal threads with diameters ranging from 25 mm to 406 mm (16 inches) and thread pitches up to 12 TPI. Its versatility makes it ideal for producing a broad range of threaded components for industrial uses.Q: When should maintenance be performed and how easy is it?

A: Routine maintenance can be conveniently carried out thanks to the easy access lubrication points. Regular checks and lubrication as guided in the user manual will help ensure smooth operation and extend the machines lifespan.Q: Where is the Lees Bradner Thread Milling Machine typically used?

A: It is primarily used in industrial environments such as manufacturing plants, machine shops, and factories that require high-precision and heavy-duty thread milling on medium to large workpieces.Q: What is the threading process involved with this machine?

A: The threading process starts with securing the workpiece in the 3-jaw manual chuck. The operator selects the desired thread pitch and speed via the quick-change gearbox, then manually controls the milling operation while the built-in coolant system manages heat for optimal results.Q: What are the main benefits of using this thread milling machine?

A: The Lees Bradner machine offers high-precision threading, robust construction for heavy-duty usage, a wide range of capacities, and ease of maintenance. Its safety features and built-in coolant system further contribute to reliable, efficient operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Thread Milling Machine Category

WMW Germany GFL-400 x 2000 mm Thread Milling Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

General Use : Thread milling for external and internal threads on cylindrical workpieces

Voltage : 380V / 50Hz

Computerized : No

Color : Other, Light Green

Huller Hille Thread Milling Machine

Price 15000 INR / Piece

Minimum Order Quantity : 1 Piece

General Use : Thread Milling Operations on Metal Workpieces

Voltage : 415 V, 3 Phase, 50 Hz

Computerized : No

Color : Other, Industrial Grey

WMW Heckert ZFWVG 250 x 2000 mm Thread Milling Machine

Price 100000.0 INR / Piece

Minimum Order Quantity : 1 Piece

General Use : WMW Heckert (Germany) make Thread & Worm Milling Machine in excellent working condition. The model of the machine is ZFWVG 250 x 2000 and it is one of the latest models of the conventional thread milling machines made by WMW Heckert company. The machine is suitable for cutting threads, splines, and gears. The machine is complete with its heavyduty Hobbing Head and also its Milling Head. The technical details are as follows

Voltage : 3 Phase, 415V, 50 Hz

Computerized : No

Color : Other, Standard WMW Paint Finish (typically Green/Grey)

Mikron 104 Thread Milling Machine

Price 1100 INR

Minimum Order Quantity : 1 Piece

General Use : Thread milling for metalworking applications

Voltage : Not available

Computerized : No

Color : Other, Metallic Grey

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry