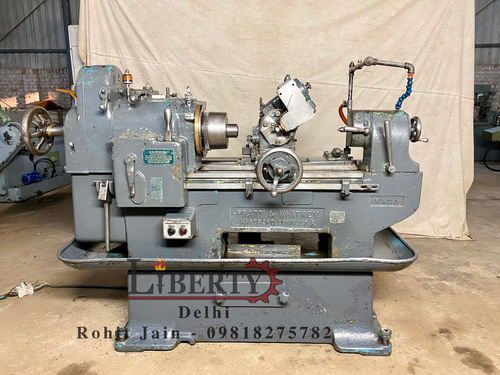

Huller Hille Thread Milling Machine

Price 15000 INR/ Piece

Huller Hille Thread Milling Machine Specification

- Rotation

- Left/Right Direction Selectable

- Model

- Huller Hille

- Product Type

- Thread Milling Machine

- General Use

- Thread Milling Operations on Metal Workpieces

- Material

- Cast Iron & Steel Components

- Type

- Horizontal Milling Type

- Capacity

- Heavy Duty, Up to 100 mm Thread Diameter

- Weight (kg)

- Approx. 2800 kg

- Computerized

- No

- Automatic

- No

- CNC Or Not

- No

- Control System

- Conventional Mechanical Control

- Table Size

- 400 mm x 1000 mm

- Table Slide Way

- Vee and Flat Type

- Magnetic Chuck Size

- 250 mm x 1000 mm

- Grinding Length

- Up to 1000 mm

- Floor Space

- Approx. 2100 mm x 2000 mm

- Spindle Speed

- 35150 RPM (Variable)

- Power

- 5 HP

- Voltage

- 415 V, 3 Phase, 50 Hz

- Dimension (L*W*H)

- Approx. 2200 mm x 2000 mm x 1600 mm

- Feature

- Robust, Accurate, Easy Operation

- Color

- Industrial Grey

- Coolant System Included

- Yes

- Main Motor Power

- 5 HP/1440 RPM

- Maximum Thread Diameter

- 100 mm

- Number of Feeds

- 8

- Min/Max Pitch Size

- 0.5 mm 12 mm

- Chuck Type

- Self-Centering 3-Jaw Chuck

- Lubrication System

- Centralized Lubrication

- Main Gearbox

- Heavy Duty Precision Gearbox

- Protection

- Overload and Earth Fault Protection

- Noise Level

- Below 85 dB (A)

- Application

- Thread Cutting, Thread Milling in Machine Shops/Workshops

- Maximum Thread Length

- 800 mm

- Lead Screw Diameter

- 40 mm

- WorkingSpeed

- Manual Feed, Adjustable

- Spindle Bore

- 80 mm

About Huller Hille Thread Milling Machine

Make - Huller Hille (Germany)

Center Height - 340 mm

Max. Length of Job - 1000 mm

Max. Diameter of Job - 400 mm

Max. Diameter over Bed - 680 mm

Max. Cutter Diameter - 200 mm

Cutter Head Rotation - 45 Degree to -30 Degree

- With Rapid Travels of the Cross-Slide & Carriage.

- Automatic Indexing.

- Automatic Cycle Working.

- Electrical Drawings, Calculation tables etc available.

- Complete with Change Gears.

- Machine is in excellent working condition

Video Link - https://youtu.be/YWjfsMrq5Bk

High-Performance Thread Milling

Engineered for durability and precision, the Huller Hille Thread Milling Machine excels in demanding thread cutting applications. Its heavy-duty construction and precision gearbox deliver smooth operation and accurate results, making it a top choice in industrial settings for threading on various metal workpieces.

Superior Versatility and Safety

The machines adjustable manual feed, variable spindle speed, and left/right rotation selection provide excellent adaptability for different thread milling jobs. Integrated overload and earth fault protection ensure both user safety and equipment reliability during prolonged operation.

Easy Operation and Maintenance

With its user-friendly conventional mechanical controls and centralized lubrication system, the Huller Hille Thread Milling Machine is designed for straightforward handling and reduced maintenance time. Its robust structure facilitates stable performance under heavy workloads.

FAQs of Huller Hille Thread Milling Machine:

Q: How does the Huller Hille Thread Milling Machine operate for thread cutting?

A: The machine uses a horizontal milling approach, combined with manual feed and variable spindle speed, to cut precise threads on metal workpieces. The operator controls the process using conventional mechanical controls, adjusting feed and speed as needed.Q: What are the benefits of the centralized lubrication system included in the machine?

A: The centralized lubrication system ensures that all critical moving components receive consistent lubrication, reducing wear and maintenance needs while increasing the lifespan of the machine and enhancing operational efficiency.Q: When should this machine be used for thread milling operations?

A: This machine is best suited for heavy-duty thread cutting and milling tasks in machine shops, workshops, or industrial environments, especially when accuracy and robustness are prioritized for metal components up to 100 mm in thread diameter.Q: Where can the Huller Hille Thread Milling Machine be installed?

A: It is ideal for installation in machine shops, manufacturing facilities, and workshops that require precision thread milling capabilities. The required floor space is approximately 2100 x 2000 mm for safe and efficient operation.Q: What process is followed for adjusting the working speed and feed?

A: Working speed is manually adjusted between 35150 RPM via mechanical controls, while the operator can select from eight feed options to suit specific thread milling requirements. This enables precise customization for each job.Q: How does the self-centering 3-jaw chuck enhance usage?

A: The self-centering 3-jaw chuck simplifies setup and secures the workpiece tightly, minimizing movement during milling. This feature helps maintain alignment and ensures consistent, accurate thread production.Q: What are the primary advantages of using this machine in metalworking shops?

A: Key advantages include its heavy-duty capability, high precision, ease of operation, and durability. Integrated safety features and ergonomic design make it a reliable solution for efficient and accurate thread milling on a wide range of metal workpieces.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Thread Milling Machine Category

WMW Germany GFL-400 x 3000 mm Thread Milling Machine

Price 100000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : Manual

Capacity : Max. Job Length 3000 mm

Table Slide Way : Other, Box Type

Voltage : 415 V

Pratt and Whitney 500 mm Thread Milling Machine

Price 50000 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : Other, Manual Gear/Lever Control

Capacity : 500 mm maximum thread length

Table Slide Way : Other, Hardened and ground

Voltage : 415V / 3 Phase / 50 Hz

Graziano Italy 3000 mm Thread Milling Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : Manual

Capacity : Up to 3000 mm Thread Length

Table Slide Way : Other, V & Flat

Voltage : 415 V / 50 Hz / 3 Phase

WMW Heckert ZFWVG 250 x 2000 mm Thread Milling Machine

Price 100000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : Manual

Capacity : Max workpiece length 2000 mm; Thread diameter up to 250 mm

Table Slide Way : Other, Hardened and ground

Voltage : 3 Phase, 415V, 50 Hz

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry