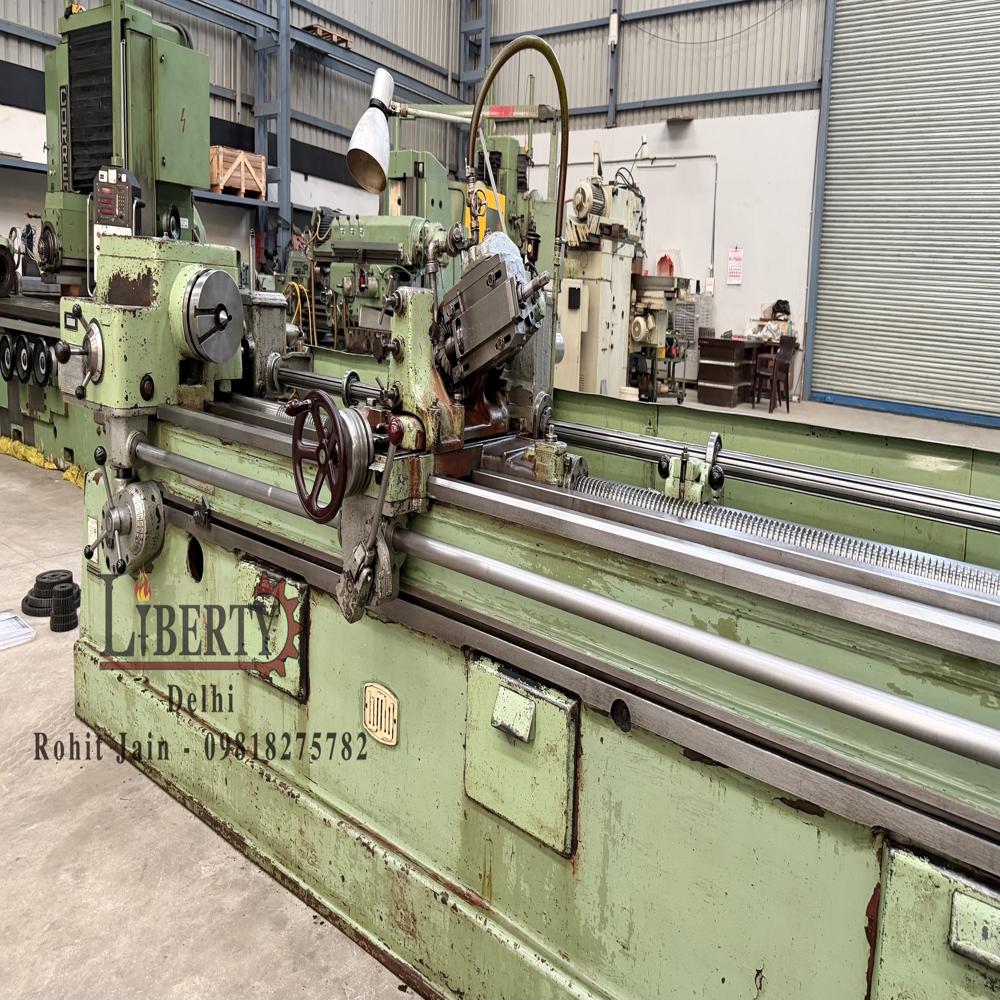

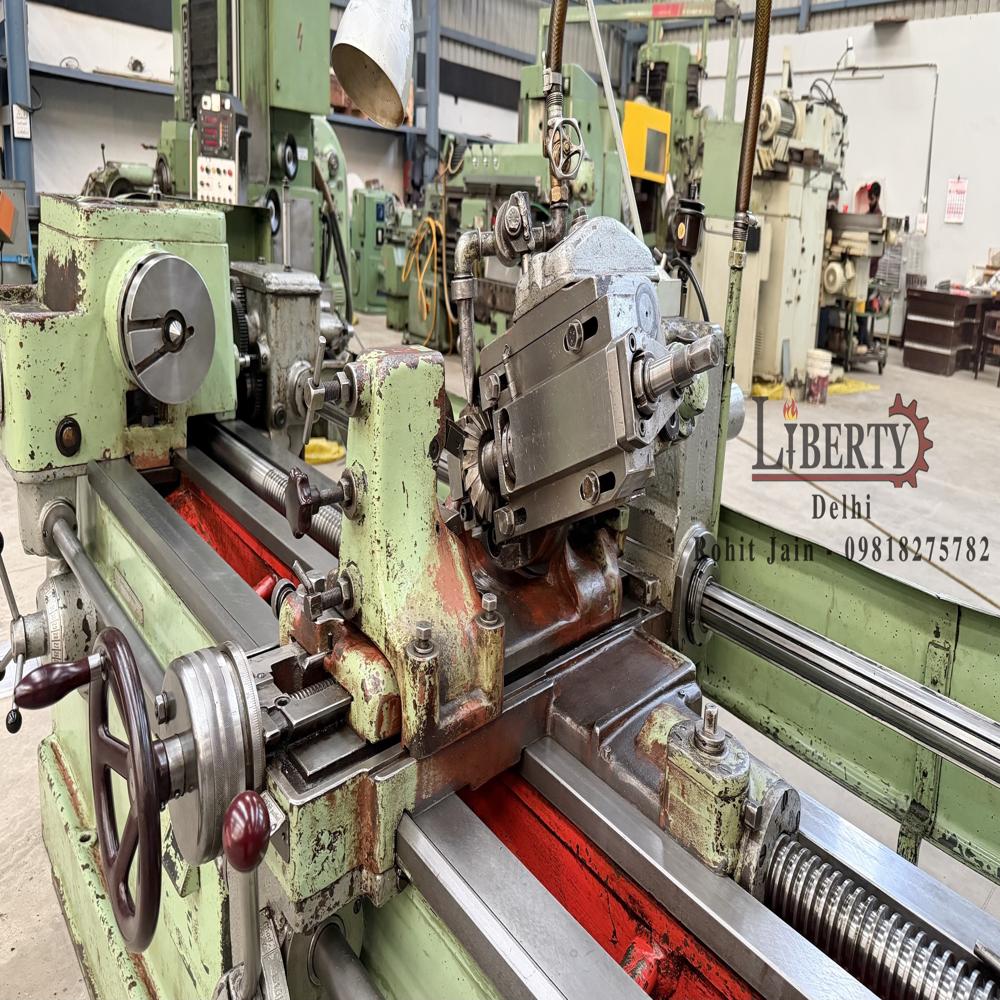

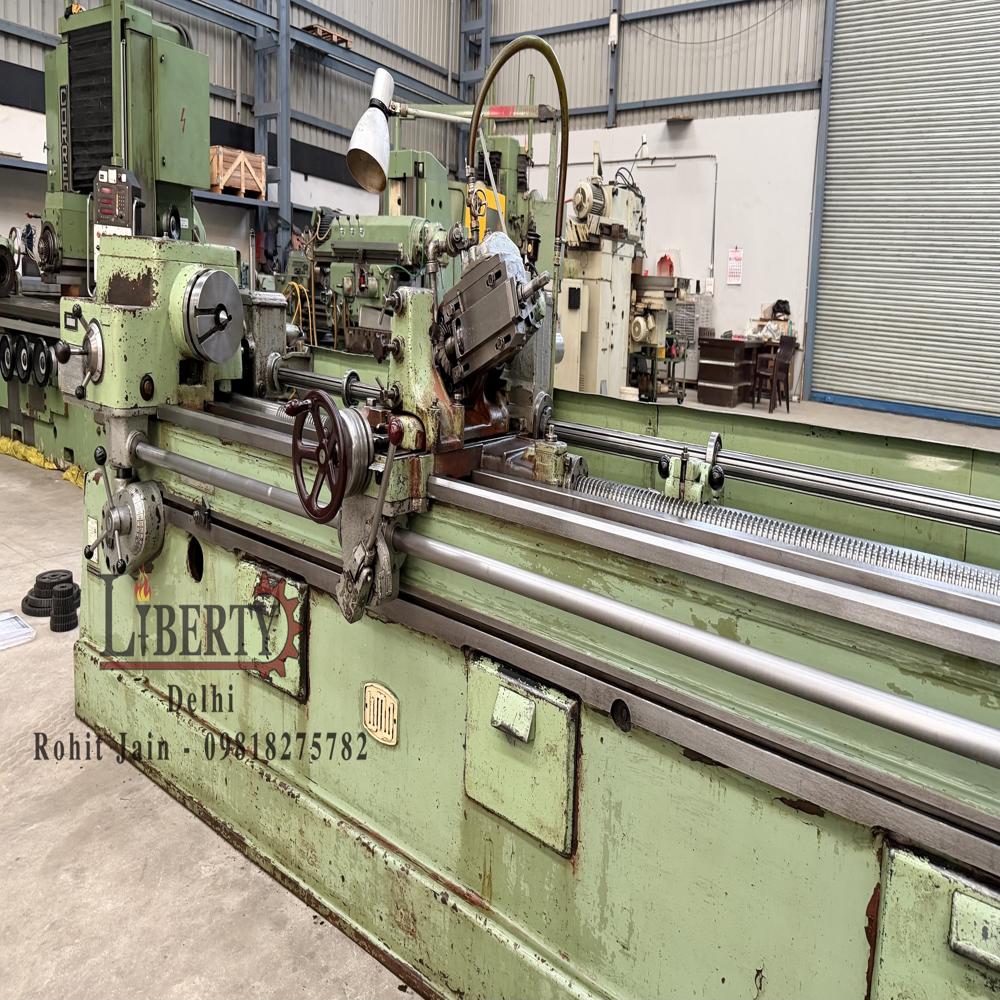

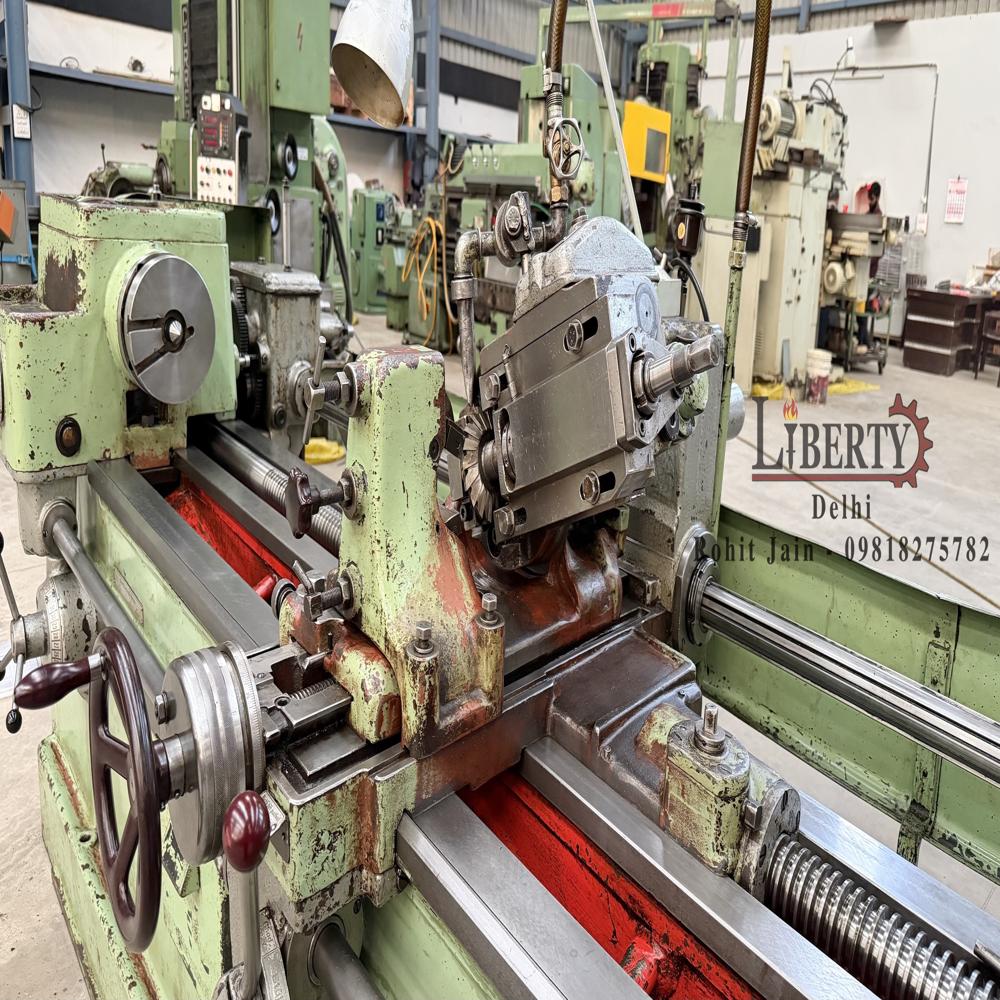

WMW Germany GFL-400 x 3000 mm Thread Milling Machine

Price 100000.0 INR/ Piece

WMW Germany GFL-400 x 3000 mm Thread Milling Machine Specification

- Model

- GFL-400 x 3000 mm

- Rotation

- Left & Right Rotation

- Product Type

- Thread Milling Machine

- General Use

- WMW (Germany) make Worm & Thread Milling Machine in excellent working condition. The model of the machine is GFL-400 and the Max. Length of Job is 3000 mm. The machine is capable of Gear Hobbing, Spline Hobbing, Spline Milling, Thread Milling & Worm Milling Operations. This machine also has a Differential Gearbox and hence can do Helical Gear Teeth Cutting as well. The technical details are as follows -

- Material

- High-grade Cast Iron & Steel

- Type

- Worm & Thread Milling Machine

- Capacity

- Max. Job Length 3000 mm

- Weight (kg)

- Approx. 6500 kg

- Computerized

- No

- Automatic

- Semi-Automatic

- CNC Or Not

- No (Conventional)

- Control System

- Manual

- Table Size

- Approx. 400 mm x 3000 mm

- Table Slide Way

- Box Type

- Magnetic Chuck Size

- 400 mm

- Grinding Length

- 3000 mm

- Floor Space

- Approx. 5500 mm x 2100 mm

- Spindle Speed

- 40 - 315 RPM (Variable)

- Power

- 7.5 kW

- Voltage

- 415 V

- Dimension (L*W*H)

- Approx. 5500 mm x 2100 mm x 2200 mm

- Feature

- Gear Hobbing, Spline Hobbing, Spline Milling, Thread Milling, Worm Milling, Differential Gearbox for Helical Gear Teeth Cutting

- Color

- Industrial Green

- Table Movement

- Automatic and Manual

- Coolant System

- Integrated

- Max. Thread Pitch

- Up to 70 mm

- Gearbox Transmission

- Hardened and ground gears

- Differential Gearbox

- Yes, for helical gears

- Bed Type

- Heavy-duty one-piece casting for vibration absorption

- Max. Job Diameter

- Up to 400 mm

- Attachment

- Multiple attachments available for different operations

- Lead Screw

- Precision hardened and ground lead screw

- Chuck Type

- 3-jaw, 4-jaw, and faceplate adaptability

- Condition

- Used, excellent working condition

- Lubrication

- Centralized automatic lubrication

About WMW Germany GFL-400 x 3000 mm Thread Milling Machine

High Precision & Versatility

With a maximum thread pitch of 70 mm and support for both left and right spindle rotations, the GFL-400 offers flexibility for various thread and gear cutting processes. Its adaptable chuck system and differential gearbox enable efficient production of helical gears, splines, and worm threads, accommodating unique job requirements with high accuracy.

Rugged Build & Reliable Operation

Engineered with a heavy-duty, one-piece cast iron bed and precision-hardened lead screw, the machine ensures long-term durability and vibration absorption. The centralized automatic lubrication and integrated coolant system safeguard consistent performance while lowering maintenance intervals.

Optimized for Industrial Use

This model is ideal for manufacturers and traders looking for a reliable thread milling solution with semi-automatic table movement, manual controls, and a large table size for accommodating lengthy workpieces. With a hardened gearbox and versatile attachments, it supports complex operations like gear hobbing and worm milling with assured productivity.

FAQ's of WMW Germany GFL-400 x 3000 mm Thread Milling Machine:

Q: How does the GFL-400 x 3000 mm Thread Milling Machine perform gear hobbing and helical gear cutting?

A: The GFL-400 is equipped with a differential gearbox, allowing precise synchronization for helical gear teeth cutting and efficient gear hobbing. Multiple attachments enable gear hobbing, spline milling, and worm thread operations on various materials.Q: What types of jobs can this thread milling machine accommodate?

A: This machine supports jobs with diameters up to 400 mm and lengths up to 3000 mm, making it suitable for gear, thread, spline, and worm milling applications. The adaptable chuck system also accommodates workpieces requiring 3-jaw, 4-jaw, and faceplate setups.Q: When is the integrated coolant and lubrication system activated?

A: The centralized automatic lubrication operates during machine use to ensure key components are consistently lubricated, minimizing wear. The integrated coolant system works simultaneously during cutting operations, helping maintain optimal temperatures and prolonging tool life.Q: Where can the GFL-400 x 3000 mm milling machine be installed?

A: With a required floor space of approximately 5500 mm x 2100 mm, the GFL-400 is suited for industrial workshops, manufacturing units, or gear production plants. Its heavy-duty build and precision guarantee stable operation in demanding settings.Q: What is the process for switching between automatic and manual table movement?

A: Operators can choose between automatic and manual table movement via the machine's controls. The semi-automatic system allows precise feeds for thread, worm, and gear milling, while manual mode facilitates setup adjustments and fine-tuning.Q: How does using this machine benefit production efficiency and machining quality?

A: High-grade cast iron and steel construction, hardened gears and lead screw, and vibration-absorbing bed enhance stability, precision, and longevity. The machine's multiple attachments and semi-automatic features support faster setup and operation, leading to improved throughput and consistent product quality.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Thread Milling Machine Category

Huller Hille Thread Milling Machine

Price 15000 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Other, Industrial Grey

Product Type : Thread Milling Machine

Floor Space : Approx. 2100 mm x 2000 mm

Table Size : 400 mm x 1000 mm

WMW Germany GFL-400 x 2000 mm Thread Milling Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Other, Light Green

Product Type : Thread Milling Machine

Floor Space : Approximately 4200 mm x 1800 mm

Table Size : 400 mm x 2000 mm

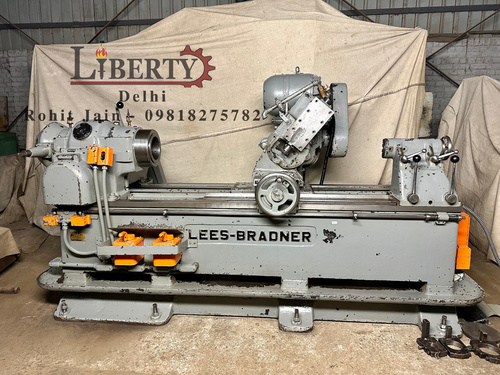

Lees Bradner HT 12 x 54 Thread Milling Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Other, Machine Grey

Product Type : Thread Milling Machine

Floor Space : Approx. 110 x 60

Table Size : 12 x 54 inch

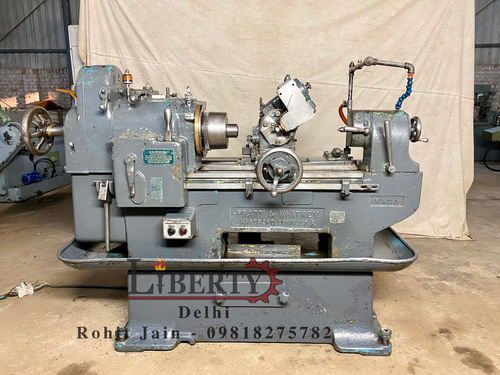

Pratt and Whitney 500 mm Thread Milling Machine

Price 50000 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Other, Industrial Grey with Blue Accents (as shown)

Product Type : Thread Milling Machine

Floor Space : Approx. 1800 mm x 1400 mm

Table Size : Approximately 700 mm x 250 mm

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry