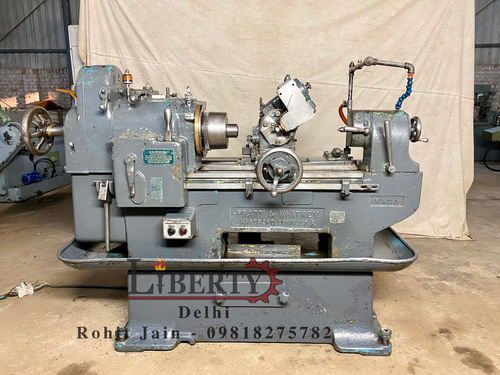

Pratt and Whitney 500 mm Thread Milling Machine

Price 50000 INR/ Piece

Pratt and Whitney 500 mm Thread Milling Machine Specification

- Rotation

- Left and Right hand threading capability

- Model

- Pratt & Whitney 500 mm

- Product Type

- Thread Milling Machine

- General Use

- Thread milling of shafts, spindles, pipes, and cylindrical components

- Material

- Cast Iron Base, Hardened Steel Components

- Type

- Horizontal Thread Milling

- Capacity

- 500 mm maximum thread length

- Weight (kg)

- Approx. 2200 kg

- Computerized

- No

- Automatic

- Semi-Automatic operation

- CNC Or Not

- Not CNC

- Control System

- Manual Gear/Lever Control

- Table Size

- Approximately 700 mm x 250 mm

- Table Slide Way

- Hardened and ground

- Floor Space

- Approx. 1800 mm x 1400 mm

- Spindle Speed

- 30-200 RPM (variable via gears)

- Power

- 3 HP to 5 HP (main motor)

- Voltage

- 415V / 3 Phase / 50 Hz

- Dimension (L*W*H)

- Approx. 2000 mm x 1600 mm x 1600 mm

- Feature

- Robust build, precise feed controls, multi-lead thread cutting

- Color

- Industrial Grey with Blue Accents (as shown)

- Thread Types

- Metric, Whitworth, Acme, NPT, and other standard thread forms

- Coolant System

- Integrated recirculating coolant pump

- Machine Condition

- Available as used/refurbished

- Feed

- Automatic and manual longitudinal table feed

- Distance Between Centers

- 500 mm

- Chuck Type

- Three-jaw or four-jaw (as per configuration)

- Accessories Included

- Change gears, thread milling heads, tool holders, coolant system

- Maximum Swing Over Bed

- Approx. 320 mm

- Leadscrew Type

- Precision ground

- Thread Pitch Range

- Up to 8 mm pitch (depending on lead gear setting)

Pratt and Whitney 500 mm Thread Milling Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Main Domestic Market

- All India

About Pratt and Whitney 500 mm Thread Milling Machine

Make - Pratt & Whitney (USA)

Model - 6 x 20

Max. Job Diameter - 150 mm (6")

Max. Job Length - 500 mm (20")

Max. Cutter Diameter - 115 mm (4.5")

Spindle Bore - 101 mm (4")

Swing Diameter Over Bed - 400 mm (16")

No. of Indexes - 2, 3, 4, 6, 8, 12, 24

Cutter Swivel Angle - 90 degree to -42 degree

- Machine is in excellent working condition.

Video of The Machine -

Versatile Thread Milling Capabilities

The machine is engineered to cut a wide range of thread typesfrom metric and Whitworth to Acme and NPTmaking it suitable for diverse industrial threading requirements. Change gears and thread milling heads facilitate multi-lead thread cutting, enhancing productivity in shaft, spindle, or pipe machining applications.

Robust Construction for Reliable Performance

The base is manufactured from cast iron for stability and vibration damping, while critical components are made of hardened steel for durability. The precision-ground leadscrew and hardened slide ways ensure accurate feed control, contributing to consistently high-quality threads and minimal maintenance over time.

Integrated Coolant and Accessory Support

The built-in recirculating coolant pump provides effective heat dissipation and chip evacuation during milling, supporting extended machine life. Included accessories like adjustable chucks, tool holders, and multiple change gears offer flexibility for various thread forms and job setups, making this machine a valuable asset for any workshop.

FAQs of Pratt and Whitney 500 mm Thread Milling Machine:

Q: How do you set the thread pitch on the Pratt & Whitney 500 mm Thread Milling Machine?

A: Thread pitch is adjusted by configuring the lead gearing system. Simply select and install the appropriate change gears, then verify the gear setting matches the desired pitchup to 8 mm depending on the specific lead gear combination used.Q: What types of threads can this machine produce?

A: The machine is capable of milling metric, Whitworth, Acme, NPT, and other standard thread forms. It comes with necessary change gears and thread milling heads to accommodate various thread geometries for both left and right hand threading.Q: When should the coolant system be used during operation?

A: Use the integrated recirculating coolant pump whenever thread milling is performed, especially on tougher materials, long threads, or during extended runs. It helps manage heat, improves finish quality, and prolongs tool life.Q: Where can the Pratt & Whitney thread milling machine be installed considering its dimensions?

A: The machine requires a floor space approximately 1800 mm x 1400 mm and has overall dimensions near 2000 mm x 1600 mm x 1600 mm. Select an accessible, stable location with sufficient power supply (415V, 3 Phase, 50 Hz) for safe and effective installation.Q: What is the process for changing between three-jaw and four-jaw chucks?

A: To change the chuck type, power down the machine and remove the existing chuck using the spindle lock mechanism. Install the preferred chuck as per your component requirementsboth three-jaw and four-jaw options are supported with this model for flexible component holding.Q: How does semi-automatic operation benefit the user?

A: Semi-automatic operation combines manual gear/lever controls with automatic longitudinal feed, streamlining thread cutting while allowing operator oversight. This results in improved consistency, easier operation, and reduced physical strain compared to fully manual milling processes.Q: What are the advantages of using precision ground components in this machine?

A: Precision-ground leadscrews and slide ways minimize wear and enable accurate feed control, ensuring that threads are produced to exact specifications and tolerances. This enhances the overall reliability and quality of thread milling operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Thread Milling Machine Category

Pratt and Whitney Thread Milling Machine

Price 12000 INR

Minimum Order Quantity : 1 Piece

Computerized : No

CNC Or Not : Other, Not CNC

Power : 3 HP motor

Spindle Speed : 60 350 RPM

Huller Hille Thread Milling Machine

Price 15000 INR / Piece

Minimum Order Quantity : 1 Piece

Computerized : No

CNC Or Not : Other, No

Power : 5 HP

Spindle Speed : 35150 RPM (Variable)

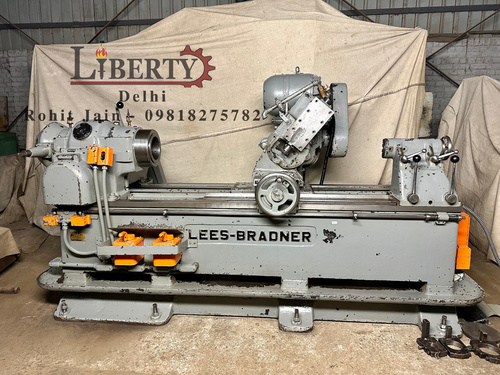

Lees Bradner HT 12 x 54 Thread Milling Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Computerized : No

CNC Or Not : Other, No

Power : 4 HP

Spindle Speed : Variable, 14 500 RPM

Graziano Italy 3000 mm Thread Milling Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Computerized : No

CNC Or Not : Other, No

Power : 7.5 kW

Spindle Speed : Approx. 20 400 RPM (Variable)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry