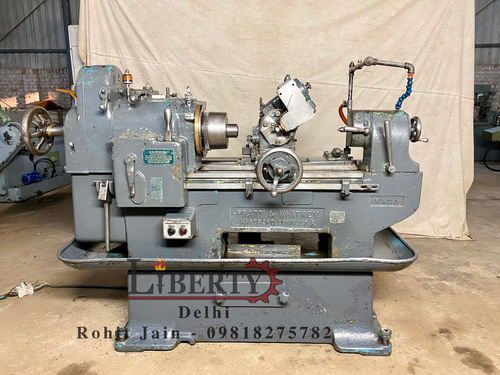

Pratt and Whitney Thread Milling Machine

Pratt and Whitney Thread Milling Machine Specification

- Rotation

- Clockwise & Counter-Clockwise

- Model

- Pratt & Whitney TM-200

- Product Type

- Thread Milling Machine

- General Use

- Industrial Thread Milling

- Material

- Cast Iron Body

- Type

- Vertical

- Capacity

- Up to 150 mm diameter

- Weight (kg)

- 1100 kg

- Computerized

- No

- Automatic

- No

- CNC Or Not

- Not CNC

- Control System

- Manual Lever

- Table Size

- 300 mm x 150 mm

- Table Slide Way

- V type cast iron

- Magnetic Chuck Size

- 200 mm x 60 mm

- Grinding Wheel Size

- 200 mm x 20 mm

- Grinding Wheel Speed

- 1600 RPM

- Grinding Length

- 300 mm

- Floor Space

- 1200 mm x 800 mm

- Fuel Tank Capacity

- 12 Liters

- Spindle Speed

- 60 - 350 RPM

- Power

- 3 HP motor

- Voltage

- 415 V

- Dimension (L*W*H)

- 1300 mm x 920 mm x 1400 mm

- Feature

- Sturdy Construction

- Color

- Industrial Grey

- Coolant System

- Integrated pump

- Max. Tool Diameter

- 18 mm

- Gearbox Type

- Heavy Duty Iron Gearbox

- Drive Type

- Belt Driven

- Surface Finish

- 0.8 to 3.2 Microns

- Installation Requirement

- Levelled floor, 3 phase power supply

- Main Motor

- 3 HP, 3 phase

- Lubrication System

- Automatic lubrication

- Min. Thread Length

- 10 mm

- Thread Pitch Range

- 0.5 mm to 6 mm

- Feed Mechanism

- Rack and Pinion

- Noise Level

- Below 80 dB

- Chuck Type

- 3 Jaw Chuck

- Max. Thread Length

- 300 mm

About Pratt and Whitney Thread Milling Machine

Make - Pratt & Whitney (USA)

Model - 4.5 inch Model C

Max. Job Diameter - 115 mm (4.5")

Max. Job Length - 305 mm (12")

Max. Cutter Diameter - 54 mm (2-1/8")

Spindle Bore - 41 mm (1-5/8")

Swing Diameter Over Bed - 305 mm (12")

- Machine is complete with lots of accessories.

- With lots of cutters, index plates, change gears etc.

- With steady, chuck, jaws, mandrels etc.

- Machine is in excellent working condition.

Video link - https://youtu.be/vxeIvuI5hRg

Precision and Robust Design

With a heavy-duty iron gearbox, sturdy cast iron body, and advanced rack and pinion feed mechanism, the TM-200 ensures high reliability and exceptional durability for continuous industrial thread milling. Its integrated coolant system and automatic lubrication protect machine elements, prolonging lifespan and maintaining precise operation during extended use.

Versatile Industrial Capability

Capable of handling thread pitches from 0.5 mm to 6 mm and threads up to 300 mm in length, this machine is perfect for a variety of industrial applications. Its spacious table and adjustable spindle speeds (60350 RPM) accommodate a diverse range of workpiece sizes and materials, providing operational flexibility for exporters, importers, manufacturers, suppliers, and traders.

User-Centric Manual Operation

Designed for straightforward operation, the manual lever system allows skilled machinists to maintain direct control over the thread milling process, ensuring accuracy without the complexity of CNC systems. The clear and responsive controls, combined with industrial-grade components, deliver dependable results and consistent surface finishes between 0.8 and 3.2 microns.

FAQs of Pratt and Whitney Thread Milling Machine:

Q: How does the Pratt & Whitney TM-200 achieve precise thread milling operations?

A: The TM-200 uses a heavy-duty iron gearbox and a rack and pinion feed mechanism to ensure smooth, accurate movements. An integrated coolant system and automatic lubrication further enhance machining precision, resulting in a consistent surface finish between 0.8 and 3.2 microns.Q: What types of threads and materials can this machine handle?

A: This thread milling machine accommodates thread pitches from 0.5 mm to 6 mm and lengths ranging from 10 mm to 300 mm. It is suited for industrial use with workpieces up to 150 mm in diameter, and its robust cast iron construction is designed to handle various metals and alloys.Q: When is it recommended to use this thread milling machine over CNC alternatives?

A: The TM-200 is ideal when manual control, cost-effective operation, and maintenance simplicity are prioritized over automation. Its design gives skilled operators precise control for custom or small-batch jobs where CNC may be unnecessary.Q: Where should the Pratt & Whitney TM-200 be installed for optimal performance?

A: For best results, install the machine on a properly leveled floor with a three-phase, 415V power supply. Adequate space (minimum 1200 mm x 800 mm) should be provided to accommodate the machines footprint and ensure safe operation.Q: What is the process for using the manual lever system for control?

A: The operator uses the manual lever controls to set the machining parameters, engage the feed mechanism, and position the workpiece using the 3-jaw chuck. Spindle speed and feed rates are adjustable via belt drive settings and gearbox selection, allowing direct hands-on precision during each thread milling cycle.Q: How does the integrated coolant and lubrication system benefit operation?

A: The integrated pump delivers coolant continuously to reduce heat buildup and clear machining debris, while the automatic lubrication system ensures critical components are always protected from wearminimizing downtime and extending machine life.Q: What advantages does this machine offer for exporters, importers, and manufacturers?

A: The TM-200s robust construction, flexibility in handling different thread sizes and materials, and low maintenance requirements make it an attractive choice for businesses involved in heavy industrial applications and international trade. Its manual operation ensures adaptability and reliability across diverse manufacturing scenarios.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Thread Milling Machine Category

WMW Heckert FZWD 160 x 2200 mm Facing and Centering Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 380 V / 50 Hz, 3phase

Computerized : No

General Use : Facing and Centering operations, shaft machining

Automatic : No

Huller Hille Thread Milling Machine

Price 15000 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 415 V, 3 Phase, 50 Hz

Computerized : No

General Use : Thread Milling Operations on Metal Workpieces

Automatic : No

Pratt and Whitney 500 mm Thread Milling Machine

Price 50000 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 415V / 3 Phase / 50 Hz

Computerized : No

General Use : Thread milling of shafts, spindles, pipes, and cylindrical components

Automatic : Other, SemiAutomatic operation

Worm Milling Machine

Voltage : 220240V

Computerized : No

General Use : Milling of worm gears

Automatic : Other, SemiAutomatic

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry