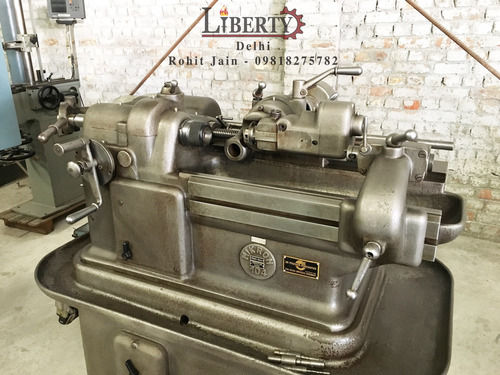

WMW Heckert FZWD 160 x 2200 mm Facing and Centering Machine

Price 100000 INR/ Piece

WMW Heckert FZWD 160 x 2200 mm Facing and Centering Machine Specification

- Rotation

- Spindle rotation

- Model

- FZWD 160 x 2200

- Product Type

- Facing and Centering Machine

- General Use

- Facing and Centering operations, shaft machining

- Material

- Heavy-duty cast iron & steel

- Type

- Horizontal

- Capacity

- Workpiece length up to 2200 mm, diameter up to 160 mm

- Weight (kg)

- Approx. 4500 kg

- Computerized

- No

- Automatic

- No

- CNC Or Not

- Not CNC, conventional machine

- Control System

- Manual, conventional controls

- Table Size

- Approx. 160 x 2200 mm

- Table Slide Way

- Precision guideways

- Magnetic Chuck Size

- Magnetic chuck not applicable

- Grinding Wheel Size

- Not applicable; machine uses facing/centering tools

- Floor Space

- Approx. 4100 x 2200 mm

- Spindle Speed

- 30 1500 rpm variable

- Power

- 7.5 kW

- Voltage

- 380 V / 50 Hz, 3-phase

- Dimension (L*W*H)

- Approx. 4100 x 2200 x 1800 mm

- Feature

- Heavy-duty, precision centering, facing

- Color

- Standard machine grey/blue

- Coolant System

- Integrated

- Main Spindle Bore

- 52 mm

- Chuck Type

- 3-jaw or 4-jaw

- Bed Width

- Approx. 420 mm

- Working Speed

- Manual adjustment

- Lubrication

- Centralized lubrication system

- Max Workpiece Length

- 2200 mm

- Max Center Height

- 160 mm

- Feed Mechanism

- Auto & manual feed

- Machine Condition

- Used/Good Condition

- Max Workpiece Diameter

- 160 mm

- Tailstock Travel

- Approx. 2200 mm

- Spindle Motor Power

- 7.5 kW

- Electrical Connection

- 380 V, 3-phase

WMW Heckert FZWD 160 x 2200 mm Facing and Centering Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Main Domestic Market

- All India

About WMW Heckert FZWD 160 x 2200 mm Facing and Centering Machine

Make - WMW - Heckert (Germany)

Model - FZWD 160

Max. Diameter of Job - 160 mm

Max. Length of Job - 2200 mm

Min. Diameter of Job - 20 mm

Min. Length of Job - 140 mm

Max. Diameter of Milling Cutter - 205 mm

Speeds of Facing Cutter - 56 rpm to 280 rpm

Speeds of Centering Cutter - 560 rpm to 1400 rpm

Serial Number of Machine - 44,162

- It is a 4-Head type Facing & Centering Machine.

- Machine is complete with a chip conveyor, coolant tank & pump.

- The machine can work in complete Auto-Cycle Mode as well as in Manual Mode.

- Machine is in excellent working condition.

Video of The Machine -

Precision & Versatility for Shaft Machining

Built to handle workpieces up to 2200 mm in length and 160 mm in diameter, the Heckert FZWD provides reliable performance for facing and centering tasks. Featuring manual controls and a robust, heavy-duty frame, it is suitable for manufacturers and machine shops requiring accuracy and consistency in non-CNC operations. Its precision guideways and adjustable spindle speeds make it ideal for a range of machining environments.

User-Friendly Design & Convenient Operation

This machine integrates convenient features such as an automatic feed mechanism, centralized lubrication, and an easy-to-operate manual control system. With both 3-jaw and 4-jaw chuck options, operators can securely handle different shaft types. The spacious machine bed, integrated coolant system, and wide table dimensions facilitate efficient setup and processing, supporting improved workflow in busy industrial settings.

FAQ's of WMW Heckert FZWD 160 x 2200 mm Facing and Centering Machine:

Q: How does the Heckert FZWD 160 x 2200 facilitate precision centering and facing operations?

A: The machine utilizes precision guideways and variable spindle speeds (30 - 1500 rpm), combined with either automatic or manual feeds, to ensure high accuracy and surface finish during both centering and facing of shafts and workpieces up to 2200 mm in length.Q: What types of workpieces can be processed on this machine?

A: It is suitable for handling shafts, cylindrical parts, and workpieces with diameters up to 160 mm and lengths up to 2200 mm, making it ideal for general facing, centering, and shaft machining tasks in manufacturing and repair industries.Q: When is manual adjustment typically used on this machine?

A: Manual adjustment is used to set spindle speeds, feeds, and positioning for tasks requiring operator control, enabling versatile machining for a variety of workpiece sizes and shapes without complex programming.Q: Where is the Heckert FZWD 160 x 2200 commonly utilized?

A: This facing and centering machine is commonly found in manufacturing facilities, machine shops, and repair workshops, especially where non-CNC conventional machining of long shafts and precision centering is required.Q: What is the process for switching between automatic and manual feed mechanisms?

A: Operators can switch between auto and manual feed by selecting the desired mode from the machine's control system, allowing flexibility for precise manual operations or efficient automated feeding during repetitive tasks.Q: How does the centralized lubrication and integrated coolant system benefit the user?

A: Centralized lubrication ensures all critical moving parts are properly maintained, reducing wear and extending machine life, while the integrated coolant system improves cutting performance and helps prevent overheating during sustained operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Thread Milling Machine Category

WMW Heckert ZFWVG 250 x 2000 mm Thread Milling Machine

Price 100000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 3 Phase, 415V, 50 Hz

Material : Other, Heavy Duty Cast Iron Body

Color : Other, Standard WMW Paint Finish (typically Green/Grey)

CNC Or Not : Other, No, Conventional

Lees Bradner Thread Milling Machine

Price 15000 INR

Minimum Order Quantity : 1 Piece

Voltage : 415 V

Material : Other, Cast Iron, Alloy Steel

Color : Green

CNC Or Not : Other, Not CNC

Lees Bradner USA LT 8 x 36 Thread Milling Machine

Price 100000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 220/440 V, 3 Phase

Material : Other, Heavy Duty Cast Iron

Color : Other, Industrial Green / Grey

CNC Or Not : Other, No

Mikron 104 Thread Milling Machine

Price 1100 INR

Minimum Order Quantity : 1 Piece

Voltage : Not available

Material : Other, Metal body

Color : Other, Metallic Grey

CNC Or Not : No, Other

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry