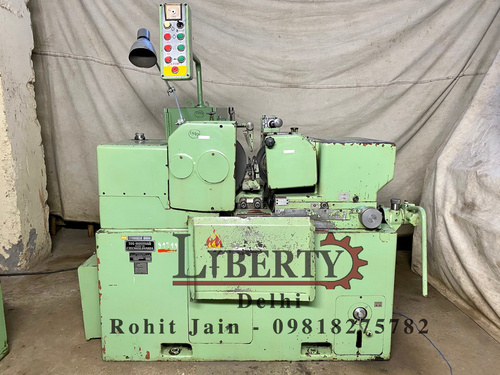

Lidkoping Centreless Grinder

Lidkoping Centreless Grinder Specification

- Model

- Lidkoping 3B

- Rotation

- Clockwise

- Product Type

- Centreless Grinder

- General Use

- Precision Grinding, Centreless Grinding Operations

- Material

- Cast Iron Body

- Type

- Heavy Duty Precision Grinder

- Capacity

- Up to 50 mm Dia x 150 mm L

- Weight (kg)

- Approx. 3500 kg

- Computerized

- No

- Automatic

- No

- CNC Or Not

- No

- Control System

- Manual

- Table Size

- Not Applicable (Centreless arrangement)

- Table Slide Way

- Hydrodynamic

- Grinding Wheel Size

- 508 mm x 304.8 mm x 203.2 mm

- Grinding Wheel Speed

- 1800 RPM

- Grinding Length

- 150 mm

- Floor Space

- 2200 mm x 1400 mm

- Spindle Speed

- Variable, up to 1800 RPM

- Power

- 7.5 HP

- Voltage

- 415 V

- Dimension (L*W*H)

- 2200 mm x 1400 mm x 1700 mm

- Feature

- High Precision, Rigid Construction, Manual Adjustment

- Color

- Lidkoping Green

- Regulating Wheel Speed

- Up to 300 RPM

- Max Job Diameter

- 50 mm

- Grinding Accuracy

- Within 5 Microns

- Main Drive Motor

- 7.5 HP, 3 Phase

- Lubrication

- Centralized Automatic Lubrication

- Regulating Wheel Size

- 305 mm x 150 mm x 127 mm

- Work Rest Blade Material

- Carbide Tipped

- Min Job Diameter

- 3 mm

- Working Speed

- Adjustable

- Hydraulic System

- Yes, for Table Slide Movement

- Coolant System

- Integrated with Machine Base

- Noise Level

- < 75 dB

About Lidkoping Centreless Grinder

- Make - Lidkoping (Sweden)

- Model - No. 2

- Grinding Wheel Size - 50 mm x 305 mm

- Grinding Wheel Turning Speeds - 1900 to 2700 rpm

- Machine is in good working condition.

Precision and Performance Combined

The Lidkoping 3B Centreless Grinder delivers exceptional accuracy and surface finishing for cylindrical components. Its heavy-duty design, featuring a robust cast iron body and carbide-tipped rest blade, ensures minimal vibration and increased longevity. The machine integrates an automatic centralized lubrication system and noise levels remain below 75 dB, offering an efficient and safer work environment. Manual adjustments allow for tailored operation, making it well-suited for diverse industrial requirements requiring repeatable, microns-level precision.

Efficient Grinding Operations

This grinder supports workpieces between 3 mm and 50 mm diameter, with an adjustable working speed and hydrodynamic table slide way for smooth movement. The integrated coolant system maintains optimal temperatures during extended operations, and the regulating wheel provides controlled feed rates up to 300 RPM. The robust hydraulic table slide movement system further optimizes processing efficiency, ensuring reliable operations even during demanding production cycles.

FAQs of Lidkoping Centreless Grinder:

Q: How does the integrated coolant system benefit the grinding process?

A: The integrated coolant system helps dissipate heat generated during grinding, reducing thermal distortion and ensuring consistent workpiece accuracy and extending tool life. This is particularly important for maintaining high-precision results in continuous production environments.Q: What are the key steps in operating the Lidkoping Centreless Grinder?

A: Operation involves setting up the work rest blade, adjusting the grinding and regulating wheels according to the job size, manually positioning the workpiece, and selecting appropriate spindle and regulating wheel speeds. Coolant and lubrication systems should be checked prior to operation for seamless grinding.Q: Where is the Lidkoping 3B Centreless Grinder most commonly used?

A: It is widely used in manufacturing facilities, tool rooms, and precision engineering workshops. It is especially suitable for exporters, importers, suppliers, and manufacturers needing high-quality cylindrical grinding for medium to large batch production.Q: When should the centralized lubrication and hydraulic systems be checked?

A: Routine checks of the centralized automatic lubrication and hydraulic table movement system should be performed daily before starting operations to ensure uninterrupted machine performance and prevent premature wear of critical components.Q: What types of jobs can this grinder handle effectively?

A: This machine is designed for centreless grinding of cylindrical parts with diameters ranging from 3 mm to 50 mm and lengths up to 150 mm. It is ideal for applications requiring high precision, such as shafts, sleeves, and pins.Q: How does manual adjustment enhance usage flexibility?

A: Manual adjustment allows operators to fine-tune the grinding parameters, accommodating different sizes and material types. This maximizes the machines adaptability, making it suitable for small-batch production or custom job requirements where automated systems are unnecessary.Q: What are the main benefits of the Lidkoping 3B compared to computerized grinders?

A: The Lidkoping 3B offers robust mechanical reliability, ease of maintenance, and hands-on control over grinding parameters. Without computerized dependencies, downtime is minimized and manual intervention allows for immediate corrections and adjustments, providing flexibility and cost-effectiveness for traditional precision grinding tasks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Centreless Grinding Machine Category

Ghiringhelli M2120 Centerless Grinder Machine

Price 21000 INR / Piece

Minimum Order Quantity : 1 Piece

CNC Or Not : CNC

Feature : Other, Automatic size compensation, auto loading/unloading system

Product Type : Centerless Grinding Machine

Computerized : Yes

Magnaghi Italy Centerless Grinding Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

CNC Or Not : Other, Not CNC

Feature : Other, Robust construction, High precision, Low maintenance

Product Type : Centerless Grinding Machine

Computerized : No

TOS BBJ6 Centerless Grinder

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

CNC Or Not : Other, Not CNC, conventional type

Feature : Other, High precision, rigid structure

Product Type : Centerless Grinder

Computerized : No

Rossi Monza Centerless Grinder

Price 7300 USD ($)

Minimum Order Quantity : 1 Piece

CNC Or Not : Other, Not CNC

Feature : Other, High precision, heavyduty construction, low vibration

Product Type : Centerless Grinder

Computerized : No

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry