Magnaghi 15 Tons Thread Rolling Machine

Price 100000 INR/ Piece

Magnaghi 15 Tons Thread Rolling Machine Specification

- Frequency

- 50 Hz

- Motor Power

- 7.5 HP

- Model No

- Magnaghi 15T

- Noise Level

- 70 dB

- Operating Temperature

- 5C to 40C

- Features

- Robust Construction, High Precision, Easy Operation

- Drive

- Electric Motor

- Lubricating System

- Automatic Oil Lubrication

- Accuracy

- 0.05 mm

- Power Rating

- 5.6 kW

- Machine Type

- Thread Rolling

- Production Capacity

- 2200 pieces/hour

- Cooling System

- Water Cooled

- Frame Type

- Heavy Duty Steel

- Voltage

- 415 V AC

- Control System

- PLC Controlled

- Product Type

- Thread Rolling Machine

- Technology

- Cold Forming

- Power Source

- Electric

- Operating Type

- Semi Automatic

- Power

- 7.5 HP

- Pressure

- 15 Tons

- Surface Treatment

- Paint Coated

- Dimension (L*W*H)

- 1800 x 1200 x 1350 mm

- Weight (kg)

- 1600 kg

- Color

- Industrial Blue

- Usage & Applications

- Thread Rolling for Metal Rods and Bars

- Maximum Blank Diameter

- 40 mm

- Safety Protection

- Emergency Stop, Overload Protection

- Phase

- 3 Phase

- Main Shaft Material

- Hardened Steel

- Standard Accessories

- Set of Thread Rolls, Tool Kit

- Roll Diameter

- 120 mm

- Maximum Thread Length

- 100 mm

- Oil Reservoir Capacity

- 20 Liters

- Machine Finish

- Anti-Corrosive Paint

- Spindle Rotation Speed

- variable, up to 1450 rpm

Magnaghi 15 Tons Thread Rolling Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Main Domestic Market

- All India

About Magnaghi 15 Tons Thread Rolling Machine

Make - Magnaghi (Italy)

Max. Pressure - 15.0 Tons

Minimum Job Diameter - 3 mm

Maximum Job Diameter - 75 mm

Max. Threading Length - 120 mm

Minimum & Maximum Thread Pitch - 0.5 mm to 5.0 mm

No. of Speeds - 4 Different Speeds

- Can work in manual as well as continuous automatic cycle feed.

- Machine has 3 sets of spare rolls with it.

- Machine is in excellent working condition.

Video of The Machine -

Precision and Efficiency

The Magnaghi 15T Thread Rolling Machine offers exceptional accuracy (0.05 mm) and high throughput, producing up to 2200 pieces per hour. Its advanced PLC control system and automatic lubrication guarantee consistent results and efficient operation, while minimizing downtime and operator intervention.

Robust Design and Safety

Constructed with a heavy-duty steel frame and a durable, anti-corrosive paint finish, this machine delivers long-lasting performance in demanding conditions. It prioritizes operator safety through integrated emergency stop functions, overload protection, and noise levels under 70 dB, ensuring a safe and comfortable work environment.

FAQs of Magnaghi 15 Tons Thread Rolling Machine:

Q: How does the Magnaghi 15T Thread Rolling Machine achieve high-precision thread rolling?

A: The Magnaghi 15T utilizes a hardened steel main shaft, PLC control system, and advanced cold forming technology to maintain a high level of dimensional accuracy (0.05 mm). Automatic lubrication and a robust frame ensure consistency and minimize vibration during high-speed operations, resulting in precise thread profiles on metal rods and bars.Q: What materials and sizes can be processed with this thread rolling machine?

A: This machine is suitable for thread rolling on metal rods and bars with blanks up to 40 mm in diameter, a thread length up to 100 mm, and compatible roll diameters up to 120 mm. Its 15-ton pressure capacity and robust construction make it ideal for a wide range of industrial metals.Q: When should I use water cooling and oil lubrication in the operation process?

A: The integrated water cooling system should be used during extended periods of operation or when processing at higher speeds to prevent overheating. The automatic oil lubrication system ensures smooth operation and longevity and should be regularly checked to confirm adequate oil levels in the 20-liter reservoir.Q: Where can this machine be deployed for maximum efficiency?

A: Magnaghi 15T is well-suited for industrial manufacturing facilities, metalworking units, and factories requiring high-volume, precise thread rolling on metal components. Its semi-automatic operation, heavy-duty design, and compact dimensions (1800 x 1200 x 1350 mm) allow efficient installation in various production environments.Q: What safety features does the Magnaghi 15T machine offer?

A: Safety is prioritized with an emergency stop function, overload protection, and a low noise level (70 dB) to protect operators. These measures, alongside robust machine construction, help to minimize workplace accidents and ensure compliance with industrial safety standards.Q: How does the semi-automatic operation benefit users?

A: Semi-automatic operation streamlines the thread rolling process by reducing manual effort, enabling rapid set-up via PLC controls, and achieving consistent results with less operator intervention. This maximizes productivity and ensures repeatable high-quality output, especially during intensive production runs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Miscellaneous Machines Category

Rusch Germany 250 mm Fully Automatic Bandsaw Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Machine Type : Automatic Bandsaw

Product Type : Other, Fully Automatic Bandsaw Machine

Usage & Applications : Metal Cutting, Industrial Manufacturing

Dimension (L*W*H) : 1900 x 800 x 1350 mm

Stanko Russia 690 mm Diameter Rotary Table

Price 50000 INR / Piece

Minimum Order Quantity : 1 Piece

Machine Type : Rotary Table

Product Type : Other, Rotary Table

Usage & Applications : For precision rotary positioning and machining in metalworking and manufacturing

Dimension (L*W*H) : Approx. 850 x 700 x 200 mm

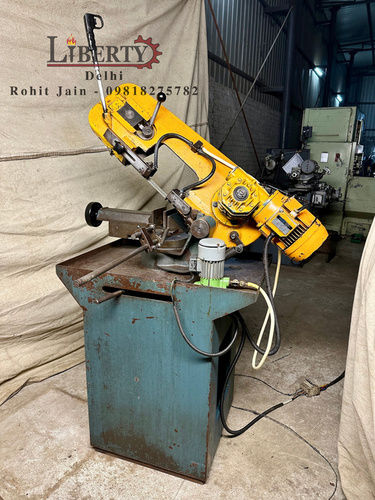

Anbas Italy Manual Bandsaw Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Machine Type : Manual Bandsaw Cutting

Product Type : Other, Bandsaw Machine

Usage & Applications : Cutting various metal and steel bars

Dimension (L*W*H) : Approximately 1100 x 650 x 1400 mm

Mitutoya Coordinate Measuring Machine (CMM)

Minimum Order Quantity : 1 Piece

Machine Type : Coordinate Measuring Machine (CMM)

Product Type : Other, Measurement machine

Usage & Applications : Inspection of components in manufacturing setups

Dimension (L*W*H) : Approximately 1500mm x 1200mm x 2200mm

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry