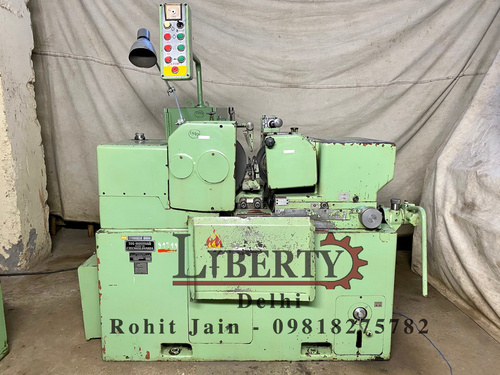

Magnaghi Automatic Centerless Grinder

Price 40000 INR/ Piece

Magnaghi Automatic Centerless Grinder Specification

- Rotation

- Clockwise/Counterclockwise

- Model

- Magnaghi

- Product Type

- Automatic Centerless Grinder

- General Use

- Precision Centerless Grinding

- Material

- Cast Iron & Alloy Steel

- Type

- Industrial Grinder

- Capacity

- 25 mm diameter

- Weight (kg)

- 1500

- Computerized

- No

- Automatic

- Yes

- CNC Or Not

- Not CNC

- Control System

- Automatic Control Panel

- Table Size

- 650 mm x 180 mm

- Table Slide Way

- V & Flat type

- Grinding Wheel Size

- 300 mm x 150 mm x 100 mm

- Grinding Wheel Speed

- 1750 rpm

- Grinding Length

- Up to 150 mm

- Floor Space

- 1800 mm x 1000 mm

- Fuel Tank Capacity

- 40 Liters

- Spindle Speed

- 2800 rpm

- Power

- 4 HP

- Voltage

- 415 V

- Dimension (L*W*H)

- 1800 mm x 1000 mm x 1400 mm

- Feature

- High Precision, Heavy Duty, Reliable Performance

- Color

- Machine Grey/Blue

Magnaghi Automatic Centerless Grinder Trade Information

- Minimum Order Quantity

- 1 Piece

- Main Domestic Market

- All India

About Magnaghi Automatic Centerless Grinder

Make - Magnaghi (Italy)

Job Grinding Diameter - 2 mm to 85 mm

Max. Grinding Wheel Size - 350 mm Diameter x 120 mm Width

Max. Control Wheel Size - 250 mm Diameter x 120 mm Width

Control Wheel Feed Angle - +5 degree to -5 degree

Width of Currently Installed Wheels - 100 mm

Control Wheel Speeds - 18 rpm to 250 rpm

- Equipped with Hydraulic Wheel Dressers.

- Automatic Rapid & Feed Travels of the Control Wheel.

- It can work in Manual, Semi-Automatic & in Fully Automatic Mode.

- Machine is in excellent working condition.

Video of The Machine -

Precision Engineering for Superior Finish

The Magnaghi Automatic Centerless Grinder is engineered to achieve exceptional accuracy and a mirror surface finish of 0.2 m Ra. Its robust construction and advanced control system ensure consistent, high-quality results even in demanding industrial environments.

Integrated Coolant and Lubrication Systems

With an automatic forced lubrication system and a highly efficient coolant system featuring a recirculation pump, this grinder maintains optimal operating temperatures and lubrication. This extends both tool life and machine durability, ensuring reliable performance over time.

Safety and User-Centric Design

Operator safety is prioritized with built-in overload protection and an emergency stop feature. The ergonomic control panel and manual micro-adjustment of the wheelhead make the machine user-friendly, while maintaining high levels of process control and efficiency.

FAQs of Magnaghi Automatic Centerless Grinder:

Q: How does the Magnaghi Automatic Centerless Grinder maintain workpiece quality?

A: The grinder achieves precise results through its manual micro-adjustment wheelhead, carbide-tipped work rest blade, and robust construction. Its integrated automatic forced lubrication and coolant recirculation minimize heat and wear, enabling mirror finishes as fine as 0.2 m Ra.Q: What safety features are included in this machine?

A: Safety is ensured with overload protection and a dedicated emergency stop button, safeguarding both the operator and the machine during operation.Q: When should manual tool changes be performed?

A: Manual tool changes are necessary when replacing the grinding wheel or adjusting the work rest blade for different job requirements. It is advised to perform these changes during scheduled maintenance or when there is a noticeable decline in grinding performance.Q: Where is this machine suitable for use?

A: The Magnaghi grinder is ideal for industrial settings requiring high precision centerless grinding, such as manufacturing plants, workshops, or metal processing facilities.Q: What is the process for adjusting the wheelhead?

A: The wheelhead can be adjusted manually using the micro-adjustment feature, allowing for fine calibration to achieve precise grinding dimensions and superior surface finish.Q: How does the coolant system benefit the grinding process?

A: The integrated coolant system, with recirculation pump, helps control temperature and remove debris during operation, which enhances both surface quality and tool longevity.Q: What are the primary benefits of using this grinder?

A: Key benefits include exceptional precision, consistent mirror finishes, efficient cooling and lubrication, low noise operation, and user-friendly safety features, making it highly reliable for continuous industrial use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Centreless Grinding Machine Category

Cimat Italy Centerless Grinding Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

General Use : Precision centerless grinding of cylindrical components

Computerized : Yes

CNC Or Not : CNC

Automatic : Other, Fully Automatic

TOS BBJ6 Centerless Grinder

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

General Use : Centerless grinding of cylindrical parts

Computerized : No

CNC Or Not : Other, Not CNC, conventional type

Automatic : Other, SemiAutomatic

Estarta Centerless Grinder

Price 5400 EUR ()

Minimum Order Quantity : 1 Piece

General Use : Precision external grinding of cylindrical parts, automotive, and bearing industries

Computerized : No

CNC Or Not : Other, Not CNC (Conventional)

Automatic : Other, SemiAutomatic

Cincinnati 2 OM Centerless Grinding Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

General Use : External and internal grinding operations for round or cylindrical parts

Computerized : No

CNC Or Not : Other, No (Conventional/Manual)

Automatic : Other, No (Manual)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry