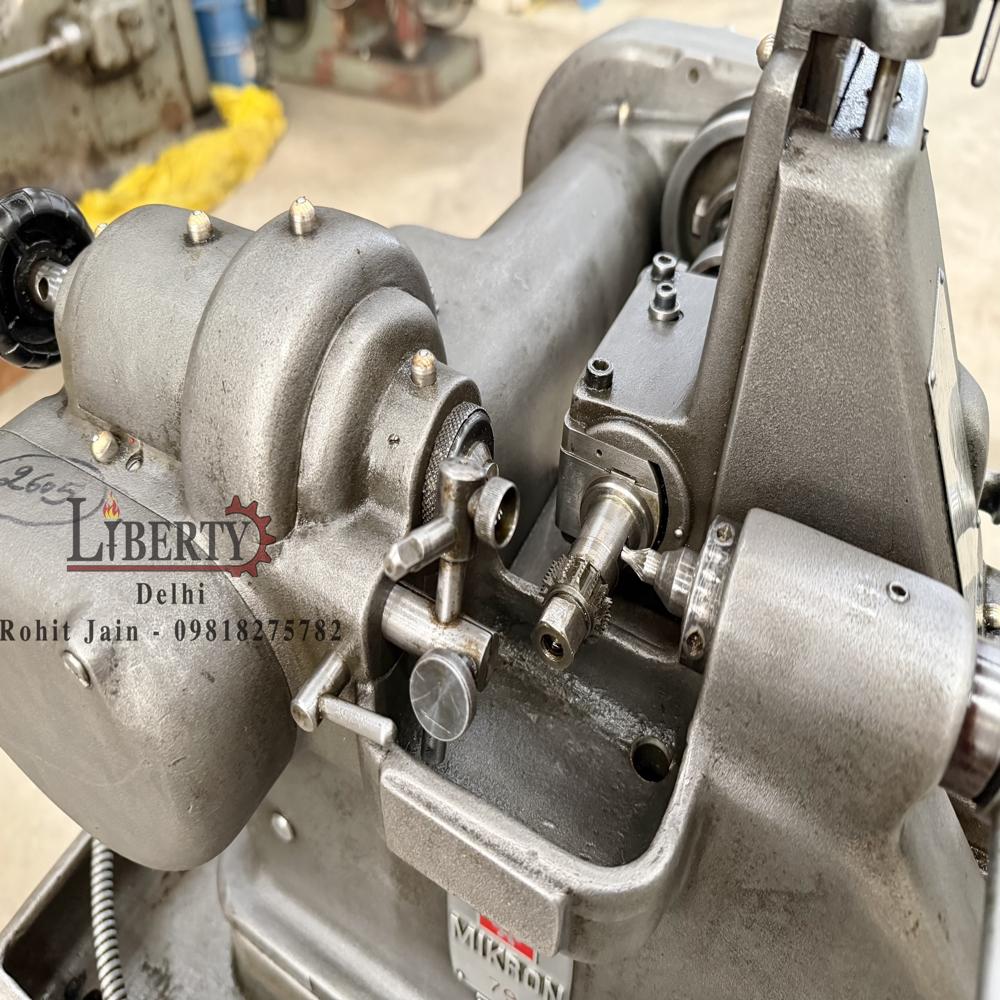

Mikron Switzerland Type 79 Precision Horizontal Gear Hobbing Machine

Price 100000.0 INR/ Piece

Mikron Switzerland Type 79 Precision Horizontal Gear Hobbing Machine Specification

- Used For

- Precision horizontal gear hobbing and cutting operations

- Output

- Precision cut gears

- Machine Type

- Mikron (Switzerland) make High-Precision Horizontal Gear Hobbing Machine in excellent condition. The model of the machine is Type 79 and it is a mechanically controlled Auto-Cycle machine. Upon starting the machine, the cutter is raised to the tooth depth, does the hobbing on the work-piece, and then falls back to its starting position. The technical details are as follows -

- Condition

- Excellent

- Feature

- Automatic cycle movement; cutter raises, engages in hobbing operation, and then returns to starting position

- Cutter Movement

- Cutter is raised to the tooth depth, performs hobbing, then returns to its starting position

- Operation Type

- Semi-automatic mechanical cycle

- Application

- Precision gear hobbing of gear blanks and work-pieces

- Model

- Type 79

- Control System

- Mechanical

About Mikron Switzerland Type 79 Precision Horizontal Gear Hobbing Machine

Superior Precision for Gear Manufacturing

The Mikron Type 79 delivers exceptional precision through its semi-automatic mechanical cycle, making it ideal for fabricating gears with tight tolerances. Its cutter movement mechanism ensures each workpiece is consistently machined to exact specifications, boosting productivity and reducing the need for manual intervention during key process stages.

Efficient and User-Friendly Operation

Operators benefit from the Mikron Type 79's straightforward mechanical controls, which enable efficient and repeatable gear hobbing cycles. The automatic raising and retracting of the cutter simplifies the gear cutting process, making the machine accessible even for users with basic mechanical knowledge while unlocking superior output quality.

FAQ's of Mikron Switzerland Type 79 Precision Horizontal Gear Hobbing Machine:

Q: How does the Mikron Type 79 gear hobbing machine operate?

A: The Mikron Type 79 features a semi-automatic mechanical cycle. On initiating the operation, the cutter is raised precisely to the desired tooth depth, performs the hobbing of the gear, and then retracts to its original starting position, ensuring uniform processing of gear workpieces.Q: What applications is the Mikron Type 79 suitable for?

A: This machine is designed for the precision hobbing of gear blanks and workpieces, making it ideal for industries involved in manufacturing, exporting, importing, and supplying high-precision gears.Q: When should I consider using a mechanically controlled gear hobbing machine like the Type 79?

A: The Mikron Type 79 is best used when high repeatability, consistent output, and precision in gear cutting operations are required, particularly in production environments where reliability is crucial.Q: Where can the Mikron Type 79 be utilized most effectively?

A: It finds optimal use in workshops, manufacturing plants, and gear-making facilities in India and abroad where precise and efficient horizontal gear hobbing is a necessity.Q: What is the process of gear hobbing on the Type 79?

A: Once the machine is started, the cutter autonomously rises to the set tooth depth, executes the hobbing operation on the gear blank or workpiece, and then returns to its initial position, simplifying the workflow.Q: How does the automatic cycle movement benefit users?

A: The automatic cycle movement ensures precise, repeatable gear cutting with minimal operator intervention, increasing productivity and reducing the likelihood of human error.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gear Hobbing Machine Category

TOS OF 71 710mm Gear Hobbing Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Used For : Precision gear cutting operations

Color : Green

Condition : Used

Machine Type : Gear Hobbing Machine

WMW Modul ZFWZ-315 Hydraulic Gear Hobbing Machine

Price 100000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Used For : Gear Cutting & Hobbing

Color : Blue

Condition : Used

Machine Type : Hydraulic Gear Hobbing Machine

Pfauter RS9K Horizontal Gear Hobbing Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Used For : Cutting gears, splines and sprockets

Color : Industrial Green

Condition : Used

Machine Type : Horizontal Gear Hobbing Machine

TOS OF 71 Gear Hobbing Machine

Price 8900 INR / Piece

Minimum Order Quantity : 1 Piece

Used For : Gear cutting and hobbing operations

Color : Green

Condition : Used

Machine Type : Gear Hobbing Machine

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry