Ribon RUR 500 Cylindrical Grinder

Ribon RUR 500 Cylindrical Grinder Specification

- Product Type

- Cylindrical Grinder

- General Use

- Precision grinding of cylindrical parts

- Material

- Cast Iron Body

- Type

- Universal Cylindrical Grinding Machine

- Capacity

- 500 mm

- Weight (kg)

- Approx. 1200 kg

- Computerized

- No

- Automatic

- Semi-Automatic

- Control System

- Manual

- Drive Type

- Electric

- Grinding Diameter

- 200 mm

- Grinding Length

- 500 mm

- Spindle Speed

- Up to 2800 RPM

- Grinding Wheel Size

- 350 x 50 x 127 mm

- Voltage

- 400 V

- Dimension (L*W*H)

- 1850 x 1200 x 1400 mm

- Feature

- High Precision, Sturdy Construction, Easy Operation

- Color

- Grey / Light Blue

- Chuck Size

- Standard

- Max Distance Center to Bed

- 200 mm

- Distance Between Centers

- 500 mm

- Tailstock Quill Travel

- 40 mm

- Wheelhead Swivel

- ±30°

- Model

- RUR 500

- Lubrication

- Centralized

- Table Swivel

- ±7°

- Optional Attachments

- Internal Grinding Attachment

- Max Workpiece Weight

- 60 kg

- Tailstock Quill Diameter

- 50 mm

- Coolant System

- Integrated

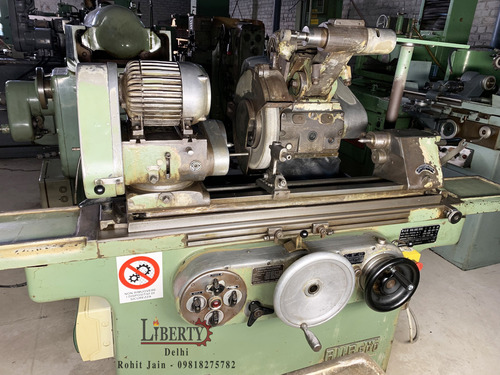

About Ribon RUR 500 Cylindrical Grinder

Ribon RUR Cylindrical Grinder

- Make - Ribon (Italy)

- Model - RUR500

- Center Height - 145 mm

- Max. Diameter of Job - 290 mm

- Length of Job - 500 mm

- Max. Wheel Diameter - 350 mm

- Wheel Thickness - 50 mm

- Type - Motorized, mechanical.

- With Internal Grinding Attachment.

- Automatic Depth Adjustment "Auto-Cut"

- Complete with Coolant tank & pump.

- 2 x Dresser & some accessories available with machine.

- Machine is in excellent working condition.

Sturdy Construction for Precision

Engineered with a robust cast iron body, the Ribon RUR 500 ensures increased stability and vibration resistance during grinding. This sturdy construction supports high-precision work, allowing operators to achieve superior results with fine tolerances, essential for demanding manufacturing environments and precision engineering applications.

Versatile and User-Friendly Operation

The RUR 500 features a universal design with manual and semi-automatic controls, making it accessible for novice and experienced technicians alike. Its integrated coolant and central lubrication systems simplify maintenance, while adjustable table and wheelhead swivels accommodate diverse grinding needs, including internal grinding with optional attachments.

FAQs of Ribon RUR 500 Cylindrical Grinder:

Q: How does the Ribon RUR 500 ensure consistent grinding accuracy?

A: The RUR 500 features high-precision spindle speeds up to 2800 RPM, stable cast iron construction, and centralized lubrication, all of which minimize vibration and wear. The table and wheelhead are independently adjustable via swivels, allowing fine-tuned control for consistent and accurate grinding results.Q: What types of workpieces can be machined on this grinder?

A: This machine is designed for cylindrical parts up to 60 kg, with a maximum grinding length of 500 mm and a diameter of up to 200 mm. Its suitable for both small- and medium-sized shafts, sleeves, bushings, and similar components requiring precise external or internal cylindrical grinding.Q: When is the internal grinding attachment necessary?

A: The optional internal grinding attachment is needed when components require precision grinding of inner surfaces or bores, in addition to external cylindrical surfaces. It adds versatility, enabling the RUR 500 to handle a wider range of part geometries and manufacturing requirements.Q: Where is the Ribon RUR 500 most effectively utilized?

A: This cylindrical grinder finds optimal use in manufacturing units, tool rooms, and maintenance workshops requiring high-precision, repeatable cylindrical grinding. It is well-suited for industries such as automotive, aerospace, and general engineering, especially where accurate tolerances are crucial.Q: What is the process for operating the machine safely and efficiently?

A: Begin by setting the workpiece between centers and adjusting the table and wheelhead swivels for the desired angle. Engage the semi-automatic controls, utilize the centralized lubrication and integrated coolant systems, and monitor spindle speed and tailstock quill travel for optimal grinding. Adhering to these steps ensures safe and precise operation.Q: How does the machines construction benefit users during prolonged operation?

A: The heavy-duty cast iron body and sturdy construction significantly reduce vibrations and mechanical deflection, leading to more consistent results, better part quality, and extended tool life. These features also minimize maintenance, increasing productivity during extended usage.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cylindrical Grinder Category

TOS BUAJ-28/650 Universal Cylindrical Grinder Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Drive Type : Electric

Control System : Manual

Weight (kg) : 2100 kg (Approx.)

Feature : Other, High Precision, Rigid Bed Construction, Tailstock with Micro Adjustment

Landis 1800 mm Heavy Duty Cylindrical Grinder

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Drive Type : Other, Electric Motor

Control System : Other, Manual Feed with Hydraulic Controls

Weight (kg) : Approx. 7000 kg

Feature : Other, Heavy Duty Design, Precision Spindle, Hydraulic Table Movement

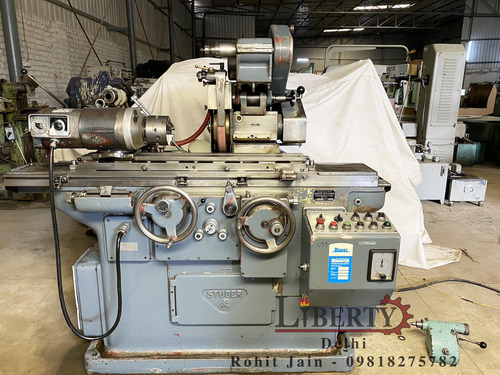

Studer Universal Cylindrical Grinder

Price 13500 INR / Piece

Minimum Order Quantity : 1 Piece

Drive Type : Other, Electric Motor Driven

Control System : Other, Siemens/Fanuc CNC or Manual

Weight (kg) : 2800 kg (Approx.)

Feature : Other, High Precision, Rigid Design, Programmable

Universal Cylindrical Grinder

Price 20000 INR / Piece

Minimum Order Quantity : 1 Piece

Drive Type : Other, Belt Drive

Control System : Other, Manual / PLC Panel (optional)

Weight (kg) : 1900 kg

Feature : Other, High Precision, Rigid Structure, Antifriction Guideways, Dustproof enclosure, Fast Center Adjustment

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry