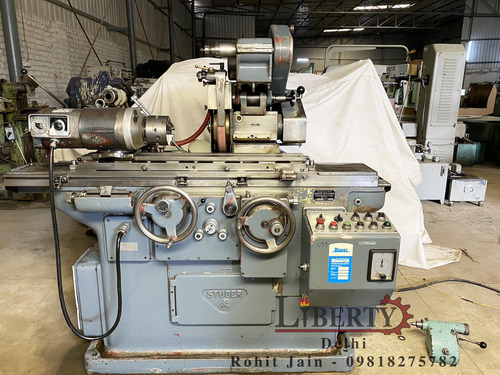

Studer Universal Cylindrical Grinder

Price 13500 INR/ Piece

Studer Universal Cylindrical Grinder Specification

- Product Type

- Universal Cylindrical Grinder

- General Use

- Precision External and Internal Grinding

- Material

- Cast Iron, Steel

- Type

- CNC or Conventional

- Capacity

- Swing over bed: up to 320 mm

- Weight (kg)

- 2800 kg (Approx.)

- Computerized

- Yes (for CNC models)

- Automatic

- Yes

- Control System

- Siemens/Fanuc CNC or Manual

- Drive Type

- Electric Motor Driven

- Grinding Diameter

- 1 320 mm

- Grinding Length

- up to 1000 mm

- Spindle Speed

- Up to 3,600 rpm

- Grinding Wheel Size

- 500 mm x 80 mm x 203 mm

- Voltage

- 400 V, 50 Hz

- Dimension (L*W*H)

- Approx. 2450 x 1600 x 1450 mm

- Feature

- High Precision, Rigid Design, Programmable

- Color

- Light Grey/Green

- Table Swivel Range

- 30° to -10°

- Internal Grinding Attachment

- Optional

- Coolant System

- Yes, with filtration

- Rapid Approach

- Yes

- Max Workpiece Weight

- 80 kg between centers

- Machine Bed

- Vibration Dampened

- Lubrication

- Centralized Automatic Lubrication System

- Main Motor Power

- 7.5 kW

- Hydraulic System

- Integrated

- Standard Accessories

- Wheel Balancing Stand, Flange, Diamond Dresser

- Application Range

- Toolroom, Production, Aerospace, Automotive

- Chuck Size

- Optional

- Wheel Head

- Swiveling Type

Studer Universal Cylindrical Grinder Trade Information

- Minimum Order Quantity

- 1 Piece

- Main Domestic Market

- All India

About Studer Universal Cylindrical Grinder

Make - Studer (Switzerland)

Model - RHU-450

Center Height - 100 mm

Length of Job - 450 mm

Grinding Wheel Size - Diameter 300 mm x 50 mm Width

Work-Head Speeds - 30 rpm to 650 rpm

Table Rotation - 10 degree to -10 degree

- Equipped with Internal Grinding Attachment.

- Machine is in excellent working condition.

Link-

https://youtu.be/sxZsC1ayOwsHigh Precision Meets Versatility

The Studer Universal Cylindrical Grinder is engineered for exceptional accuracy and flexibility, supporting a wide range of grinding tasks. With CNC or conventional models available, this grinder adapts seamlessly to both complex production runs and custom toolroom jobs. Suitable for cast iron, steel, and more, it provides meticulous surface finishes for components across aerospace, automotive, and precision engineering sectors.

Superior Construction and Efficient Operation

Constructed with a vibration-dampened bed and robust cast iron frame, the machine remains stable during high-precision cycles. Its integrated hydraulic and coolant systems with filtration, along with a centralized automatic lubrication system, protect components from wear and overheatingmaximizing lifespan and performance. The rapid approach, swiveling wheel head, and programmable features empower operators to achieve consistent, reliable grinding results.

FAQs of Studer Universal Cylindrical Grinder:

Q: How does the Studer Universal Cylindrical Grinder ensure high precision in grinding?

A: The grinder achieves exceptional accuracy through its rigid, vibration-dampened machine bed, CNC or manual controls, and high-quality components such as an integrated hydraulic system and centralized automatic lubrication. These features minimize errors and enhance repeatability during both external and internal grinding operations.Q: What types of workpieces and materials can be processed with this grinder?

A: It is capable of handling workpieces up to 80 kg between centers and supports a swing over bed of up to 320 mm, making it suitable for parts used in automotive, aerospace, and toolroom applications. It efficiently grinds materials like cast iron and steel.Q: When would the internal grinding attachment be used, and is it included as standard?

A: The internal grinding attachment is optional and is particularly useful when precision internal diameters or complex bore geometries must be ground. It is not included by default but can be added based on application needs.Q: Where is the Studer Universal Cylindrical Grinder most commonly utilized?

A: This machine is widely deployed in toolrooms, production lines, aerospace and automotive manufacturing facilities, and precision engineering workshops where reliable surface finish and dimensional accuracy are paramount.Q: What is the process for maintaining and servicing the machine?

A: Maintenance is simplified with the centralized automatic lubrication system for smooth operation, an integrated hydraulic system, and a coolant system with filtration. Regular checks ensure longevity, while included accessories like the wheel balancing stand aid efficient maintenance.Q: How does rapid approach functionality benefit operators?

A: Rapid approach enables swift alignment of the grinding wheel with the workpiece, significantly reducing setup and cycle times. This enhances productivity, especially when handling multiple or complex grinding operations.Q: What are the key advantages of choosing a Studer Universal Cylindrical Grinder for production?

A: Key benefits include high precision, programmable CNC capability, rigid design for stability, versatility for processing various workpieces, reduced downtime through automatic lubrication, and efficient coolingensuring superior results and minimum operator intervention.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cylindrical Grinder Category

TOS BUA 31/1000 Cylindrical Grinder

Price 8950 INR / Piece

Minimum Order Quantity : 1 Piece

Capacity : 1000 mm

Grinding Length : Up to 1000 mm

Dimension (L*W*H) : 3100 x 1650 x 1750 mm

Grinding Wheel Size : 300 x 40 x 127 mm

TOS BUAJ 28 1000 Universal Cylindrical Grinder

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Capacity : Between Centers 1000 mm

Grinding Length : 1000 mm

Dimension (L*W*H) : 2900 x 1600 x 1400 mm

Grinding Wheel Size : 400 x 50 x 203 mm

Jones and Shipman 1212E High Precision Cylindrical Grinder

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Capacity : 200 mm (Swing over table)

Grinding Length : 300 mm

Dimension (L*W*H) : 1700 x 1200 x 1500 mm

Grinding Wheel Size : 350 mm x 38 mm x 127 mm

TOS BH 25A 630 mm Heavy Duty Cylindrical Grinder

Price 50000 INR / Piece

Minimum Order Quantity : 1 Piece

Capacity : 630 mm

Grinding Length : 630 mm

Dimension (L*W*H) : 2800 x 1600 x 1450 mm

Grinding Wheel Size : 350 x 40 x 127 mm

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry