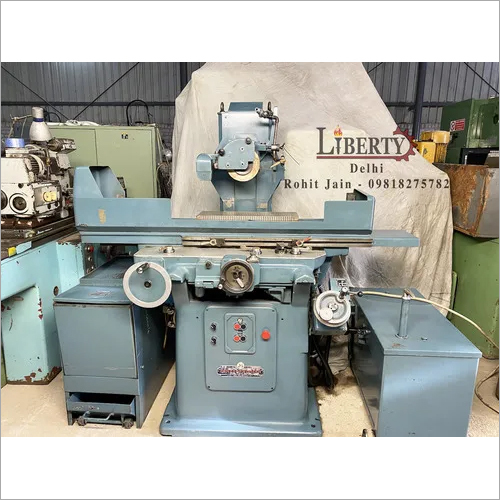

TOS BRH 20A Surface Grinding Machine

Price 3000 INR/ Piece

TOS BRH 20A Surface Grinding Machine Specification

- Model

- BRH 20A

- Rotation

- Clockwise

- Product Type

- Surface Grinding Machine

- General Use

- Precision Surface Grinding

- Material

- Cast Iron Base, Alloy Steel Components

- Type

- Horizontal Surface Grinder

- Capacity

- Heavy Duty

- Weight (kg)

- Approx. 1450 kg

- Computerized

- No

- Automatic

- No

- CNC Or Not

- No (Conventional)

- Control System

- Manual

- Table Size

- 500 x 200 mm

- Table Slide Way

- V and Flat Guideways

- Magnetic Chuck Size

- 500 x 200 mm

- Grinding Wheel Size

- 200 x 20 x 76 mm

- Grinding Wheel Speed

- 2800 RPM

- Grinding Length

- 500 mm

- Floor Space

- 1600 x 1200 mm

- Fuel Tank Capacity

- 50 L

- Spindle Speed

- 2800 RPM

- Power

- 3 kW

- Voltage

- 415 V

- Dimension (L*W*H)

- Approx. 1600 x 1200 x 1500 mm

- Feature

- Rigid Construction, High Precision

- Color

- Standard Green

- Main Motor Power

- 3 HP

- Phase

- Three phase

- Surface Finish Achievable

- Up to 2 microns

- Column Vertical Feed

- 0.02 0.5 mm/rev

- Table Cross Travel

- 230 mm

- Lubrication System

- Centralized

- Hand Wheel Graduation for Vertical Feed

- 0.01 mm

- WorkingSpeed

- Up to 18 m/min (table travel)

- Coolant System

- Provided

- Hydraulic System

- Built-in for Table Movement

- Installation Type

- Floor Mounted

- Maximum Distance from Table Surface to Spindle Center

- 370 mm

- Table Longitudinal Travel

- 550 mm

About TOS BRH 20A Surface Grinding Machine

Make - TOS (Czech Republic)

Model - BRH-20A

Max. Job Size - 200 mm x 630 mm

Current Magnet Size - 200 mm x 600 mm

Grinding Wheel Size - Diameter 250 mm x 40 mm Width

Max. Longitudinal Travel - 710 mm

Max. Distance b/w Wheel-Axis & Magnet Top - 335 mm

- Column Moving type design for Transverse Travel.

- With Coolant Filtration Unit, Coolant Tank, pump etc.

- Motorized Rapid Vertical Travel of the Wheel-Head.

- Machine is in excellent working condition.

Video link - https://youtu.be/W5K-JeN-zEU

High-Precision Grinding Performance

Achieve exceptional surface finishes with the BRH 20A, reaching up to 2 microns thanks to its rigid construction and precision engineering. The built-in hydraulic and centralized lubrication systems contribute to consistent, high-quality results, making it a preferred choice for demanding machining tasks.

Robust and Versatile Design

Constructed with a cast iron base and alloy steel components, the BRH 20A is designed to withstand intensive use. The spacious table and magnetic chuck accommodate a range of workpieces, suitable for various industrial users including exporters, importers, manufacturers, suppliers, and traders.

User-Friendly Manual Controls

Equipped with manually operated controls, the BRH 20A offers fine adjustments with vertical feed graduation of 0.01 mm per hand wheel revolution. Its conventional interface provides reliable, direct manipulation for precise grinding tasks, ideal for operators favoring hands-on machining.

FAQs of TOS BRH 20A Surface Grinding Machine:

Q: How does the TOS BRH 20A achieve high precision surface finishes?

A: The machines rigid cast iron base, precision-ground guideways, and micron-grade hand wheel graduations allow operators to achieve surface finishes up to 2 microns. The centralized lubrication and coolant systems further support consistent and smooth grinding operations.Q: What types of materials can be processed on this grinding machine?

A: The BRH 20A is designed for heavy-duty grinding of a range of ferrous and non-ferrous metals, supported by its robust magnetic chuck and alloy steel components. Its commonly used in tool rooms, maintenance shops, and manufacturing for precision surface finishing.Q: When is the centralized lubrication system used during operation?

A: The centralized lubrication system functions continuously while the machine is in operation, ensuring that all critical moving components are consistently lubricated for minimal wear and optimal performance throughout the grinding cycle.Q: Where is the TOS BRH 20A typically installed?

A: This surface grinder is intended for floor mounting and requires a space of approximately 1600 x 1200 mm. It is commonly used in workshops, manufacturing facilities, and tool rooms where precision surface grinding is essential.Q: What is the process for adjusting the vertical feed on this machine?

A: Operators can finely tune the columns vertical feed by using the hand wheel, which offers graduations in increments of 0.01 mm. This precise adjustment ensures controlled depth during the grinding process, crucial for maintaining accuracy.Q: How does the built-in hydraulic system benefit table movement?

A: The integrated hydraulic system provides smooth, reliable longitudinal table movement up to 18 m/min, reducing manual effort and maintaining consistent feed rates. This results in more uniform grinding, especially on larger workpieces.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Surface Grinder Category

MAS BPV 300 x 1500 Vertical Cup Grinding Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Feature : Other, High Precision, Rigid Construction

Automatic : No

CNC Or Not : Other, No

Control System : Manual

Jakobsen High Precision Surface Grinder

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Feature : Other, High Precision, Smooth Table Movement, Robust Build

Automatic : No

CNC Or Not : Other, Not CNC

Control System : Manual

Freeport Taiwan Manual Surface Grinder

Price 225000 INR / Piece

Minimum Order Quantity : 1 Piece

Feature : Other, Sturdy Construction, Precision Grinding, Low Maintenance

Automatic : No

CNC Or Not : Other, Not CNC (Manual)

Control System : Other, Manual Control

Jones & Shipman Surface Grinder Machine

Price 3750 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Feature : Other, Surface Grinding

Automatic : No

CNC Or Not : Not CNC, Other

Control System : Manual

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry