Universal Tool & Cutter Grinder

Universal Tool & Cutter Grinder Specification

- Machine Type

- Tool & Cutter Grinder

- Usage

- Industrial

- Tool Type

- Grinding Tool

- Features

- Universal Tool & Cutter Grinder

- Product Type

- Universal Tool & Cutter Grinder

- Color

- Any

About Universal Tool & Cutter Grinder

Universal Tool & Cutter Grinder PONAR

Make - Ponar (Poland)

Model - NUA25

Table Size - 915 mm x 135 mm

Centre Height - 140 mm

Distance between Centres (one side Chuck & other side Tailstock) - 465 mm

Distance between Centres (both side plain centres) - 685 mm

Turning Angle of Table - +/- 45°

Table Movement - Mechanical (Rack-Pinion)

- Machine is complete with steady, and all other accessories.

Versatility in Industrial Tool Sharpening

This grinder is designed to handle a wide array of industrial tools, making it ideal for reconditioning and sharpening tasks in workshops and manufacturing units. Its universal nature allows you to work with multiple tool types, enhancing operational flexibility.

Trusted by Professionals Across India

Manufacturers, exporters, importers, suppliers, and traders throughout India trust this tool for its reliability and consistent performance. The wide network ensures timely service, parts availability, and technical support for varied industrial needs.

FAQs of Universal Tool & Cutter Grinder:

Q: How can the Universal Tool & Cutter Grinder be used in an industrial setting?

A: The grinder is used to precisely sharpen and recondition industrial cutting tools such as drills, end mills, and various lathe tools, thereby extending their lifespan and improving machining accuracy.Q: What tools can be sharpened with this Universal Tool & Cutter Grinder?

A: This machine can sharpen a variety of industrial tools including milling cutters, drill bits, reamers, taps, and other precision cutting instruments used in manufacturing and maintenance operations.Q: When should I use a Universal Tool & Cutter Grinder?

A: You should use this grinder whenever your cutting tools become dull or require restoration to their original geometry, ensuring sustained efficiency and finishing quality in your machining processes.Q: Where can I purchase the Universal Tool & Cutter Grinder in India?

A: It is available through a broad network of exporters, importers, manufacturers, suppliers, and traders throughout India, ensuring easy access for industrial customers nationwide.Q: What is the process involved in grinding tools with this machine?

A: The process includes securing the tool in the grinders fixture, adjusting the angles and settings as needed, and operating the abrasive wheel to restore or sharpen the cutting edge of the tool.Q: What are the main benefits of using a Universal Tool & Cutter Grinder?

A: Using this grinder increases tool longevity, reduces operational costs by minimizing tool replacement, and enhances machining precision, which collectively improve overall productivity in industrial applications.Q: How does this machine contribute to efficiency in industrial operations?

A: By providing accurate and repeatable tool sharpening, it minimizes downtime, ensures consistent tool performance, and supports high-quality output in demanding production environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Tool & Cutter Grinder Category

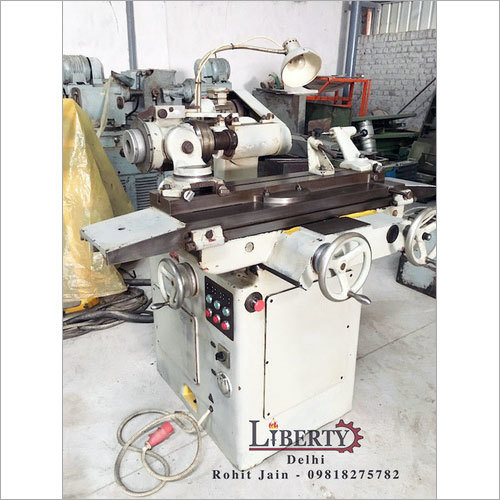

TOS Tool Cutter Grinder with Cylindrical Grinding Attachment

Price 50000 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Swiveling work head, adjustable table, tailstock, cylindrical grinding attachment

Operation Type : Other, Manual, semiautomatic

Operate Method : Manual and mechanically adjustable

Processing Type : Tool and Cutter Grinding, Cylindrical Grinding

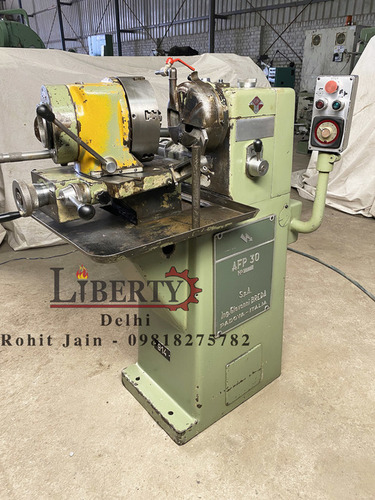

Breda AFP 30 Drill Grinding Machine

Price 10000 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Angle adjustable, Integrated coolant tray, Quick clamping system

Operation Type : Other, Electrical, Motordriven

Operate Method : Manual / Semiautomatic

Processing Type : Drill Bit Resharpening

TOS BN 102A Universal Tool and Cutter Grinder

Price 50000 INR / Piece

Minimum Order Quantity : 1 Piece

Features : High Precision, Swiveling Work Table, Versatile Tool Holders, Internal and External Grinding, Adjustable Grinding Head

Operation Type : Other, Manual

Operate Method : Manual Operation with Precision Hand Wheels

Processing Type : Universal Tool and Cutter Grinding

Cuoghi Italy APE-60 Tool Sharpening Machine

Price 100000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Features : High rigidity construction, micrometric settings, quick setup, multitool compatibility, Italian build quality

Operation Type : Other, Manual with semiautomatic functions

Operate Method : Manual/automatic via control panel

Processing Type : Tool sharpening, grinding, and reconditioning

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry