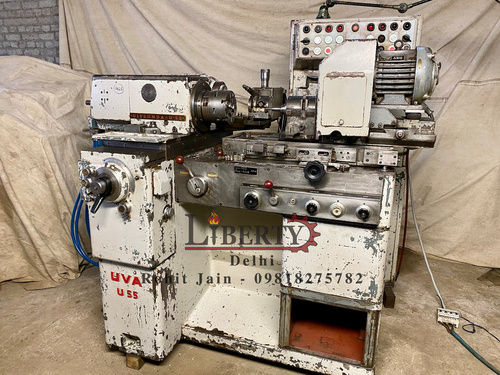

UVA U-55 Internal Grinding Machine

Price 100000.00 INR/ Piece

UVA U-55 Internal Grinding Machine Specification

- Computerized

- Yes

- Automatic

- Yes

- CNC Or Not

- Normal

- Control System

- PLC Control

- Voltage

- 220 Volt (v)

- Color

- White

- Warranty

- yes

UVA U-55 Internal Grinding Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Main Domestic Market

- All India

About UVA U-55 Internal Grinding Machine

Make - UVA (Sweden)

Model - U-55

Max. Job Swing Diameter - 240 mm

Max. Table Travel - 160 mm

Work-Head Speeds - 240 rpm to 1400 rpm

Spindle Diameter - 80 mm

Work-Head Rotation - 0 degree to 60 degree

Chuck Diameter - 160 mm

Max. Distance between Chuck to Spindle Support - 370 mm

- Rapid Cross Travel of the Work-Head.

- Rapid Approach & Retraction of the Table.

- Equipped with Hydraulic Wheel Dresser.

- Features like Auto-Cut, Auto-Compensation, Spark-Out etc.

- Machine can work in Auto-Cycle Mode.

- Operating Manual & Electrical Drawings are available.

- Complete with Accessories as shown.

- Machine is in excellent working condition.

Video of The Machine -

Advanced PLC-Controlled Grinding

The UVA U-55 Internal Grinding Machine incorporates a modern PLC control system, allowing seamless automation and precise adjustment. This optimizes the internal grinding process, delivering consistent results without extensive manual intervention. The computerized system further aids in minimizing operator errors and streamlining workflow.

Reliable and Versatile Operation

Designed for easy integration in manufacturing setups, the U-55 runs on a standard 220 Volt supply. Its automatic functions support a variety of internal grinding tasks, making it suitable for exporters, importers, manufacturers, and suppliers. The robust build and warranty coverage add an extra layer of reliability.

FAQ's of UVA U-55 Internal Grinding Machine:

Q: How does the PLC control system enhance the performance of the UVA U-55 Internal Grinding Machine?

A: The PLC control in the UVA U-55 facilitates automated and consistent operation by regulating grinding parameters with accuracy. This reduces manual oversight and ensures repeatable high-quality results for internal grinding tasks.Q: What types of industries can benefit from using the UVA U-55 Internal Grinding Machine?

A: This machine is ideal for industries requiring precision internal grinding, such as automotive, aerospace, and general manufacturing. Its versatility supports exporters, importers, manufacturers, suppliers, and traders dealing with high-quality grinding operations.Q: When should I consider using a non-CNC but computerized automatic grinding machine like the UVA U-55?

A: If your production requires automated internal grinding without the complexity of CNC programming, the UVA U-55 offers computerized controls and automation that streamline processes while remaining straightforward to operate.Q: Where is the UVA U-55 Internal Grinding Machine manufactured and supplied from?

A: The UVA U-55 is manufactured and exported from Sweden, a country renowned for its engineering excellence. It is available to global customers through a network of suppliers and traders.Q: What is the process for setting up and operating the UVA U-55 Internal Grinding Machine?

A: Installation involves connecting to a 220 Volt power supply and configuring the PLC system for your specific grinding requirements. The automatic and computerized features allow for user-friendly programming and operation.Q: How does the automatic functionality improve usage efficiency?

A: Automatic operation reduces manual input, allowing operators to focus on quality control and batch processing. This leads to increased throughput and less downtime during production cycles.Q: What are the key benefits of choosing this machine with a warranty?

A: Purchasing the UVA U-55 with a warranty provides reassurance of quality and support, ensuring prompt assistance for any operational issues and minimizing unexpected repair costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Internal Grinding Machine Category

Voumard Type 5s Long Table Internal Grinding Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Other, Industrial Grey

General Use : Internal grinding of cylindrical components

Computerized : No

Feature : Other, Long Table, Precision Grinding, Highspeed Spindle

Fortuna Germany SIP Internal and Face Grinding Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Other, Standard Industrial Grey

General Use : Internal and Face Grinding Applications

Computerized : No

Feature : Other, Precision Grinding, High Surface Finish

TOS BDE-5-350 Heavy Duty Internal Grinding Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Other, Blue & Grey

General Use : Heavy Duty Internal Grinding

Computerized : No

Feature : Other, Rugged Construction, Precision Grinding, Easy Operation

Jung Berlin Internal Grinder

Price 6000 USD ($)

Minimum Order Quantity : 1 Piece

Color : Other, Grey

General Use : Internal Grinding Operations

Computerized : No

Feature : Other, High Precision, Robust Construction, Smooth Operation

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry