WMW UPW 12.5.1 Automatic Thread Rolling Machine

Price 25000 INR/ Piece

WMW UPW 12.5.1 Automatic Thread Rolling Machine Specification

- Features

- Heavy-duty frame, automatic feeding, overload protection

- Lubricating System

- Centralized Lubrication

- Frequency

- 50 Hz

- Motor Power

- 7.5 kW

- Model No

- UPW 12.5.1

- Frame Type

- Rigid Cast Iron Frame

- Operating Temperature

- 5C to 45C

- Machine Type

- Thread Rolling

- Production Capacity

- Upto 600 pieces/hour

- Drive

- Gear Driven

- Control System

- PLC-Based Control

- Noise Level

- < 78 dB

- Cooling System

- Integrated Coolant System

- Power Rating

- 7.5 kW

- Voltage

- 415 V

- Accuracy

- High Precision Thread Forming

- Product Type

- Automatic Thread Rolling Machine

- Technology

- Cold Forming / Thread Rolling

- Power Source

- Electricity

- Operating Type

- Manual

- Power

- 7.5 kW

- Pressure

- Upto 12.5 tons

- Surface Treatment

- Paint Coated

- Dimension (L*W*H)

- Approx. 2500 x 1600 x 1600 mm

- Weight (kg)

- Approx. 4650 kg

- Color

- Green

- Warranty

- yes

- Usage & Applications

- Thread rolling of bolts, screws, studs, and other fasteners

- Base

- Vibration absorbing base

- Max Thread Length

- 90 mm

- Operator Panel

- Touch-type Interface

- Min Thread Length

- 10 mm

- Maximum Pitch

- 3.0 mm

- Electric Panel

- Dust & Vibration Protected

- Safety Systems

- Emergency Stop, Guard Interlocks

- Minimum Pitch

- 0.7 mm

- Roll Die Diameter

- 120 mm

- Max Blank Diameter

- 30 mm

- Max Blank Length

- 120 mm

- Input supply

- 3 Phase AC

- Roll Die Width

- 50 mm

- Maintenance

- Low maintenance design

WMW UPW 12.5.1 Automatic Thread Rolling Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About WMW UPW 12.5.1 Automatic Thread Rolling Machine

Make - WMW (Germany)

Model - UPW 12.5.1

Max. Rolling Force - 12.5 Tons

Job Diameter Range - 3 mm to 70 mm

Max. Thread Length - 8000 mm

Max. Thread Length (in Plunge Method) - 125 mm

Maximum Pitch - 4 mm

Thread Roll Size - Width 125 mm x 195 mm Diameter

Spindle Speeds - 20 rpm to 90 rpm

Type - Hydraulic

- It can work in auto-cycle mode and manual mode.

- Machine is in excellent working condition.

Video of The Machine -

Robust Construction and Advanced Technology

Designed with a rigid cast iron frame and vibration absorbing base, the WMW UPW 12.5.1 guarantees stability and precision under demanding conditions. Its cold forming/thread rolling technology promotes superior thread integrity and surface finish, making it suitable for manufacturing high-quality fasteners.

Efficient and Safe Operation

The machine is equipped with an integrated coolant system, centralized lubrication, overload protection, and advanced safety systems including emergency stop and guard interlocks. The touch-type operator panel and intuitive PLC control ensure straightforward operation and minimize downtime.

Versatile Applications

Capable of handling blanks up to 120 mm in length and diameters up to 30 mm, the UPW 12.5.1 accommodates a range of fastener sizes and types. Automatic feeding and high throughput (up to 600 pieces per hour) make it ideal for export, import, manufacturing, and supply operations.

FAQs of WMW UPW 12.5.1 Automatic Thread Rolling Machine:

Q: How does the WMW UPW 12.5.1 thread rolling machine operate?

A: The WMW UPW 12.5.1 utilizes a cold forming/thread rolling process, where roll dies of 120 mm diameter and 50 mm width precisely form threads onto fastener blanks. Operation is controlled via a manual interface complemented by automatic feeding and a PLC-based control system for consistent results.Q: What types of fasteners can be processed with this machine?

A: The UPW 12.5.1 is designed for thread rolling of bolts, screws, studs, and other cylindrical fasteners with blank diameters up to 30 mm and lengths up to 120 mm, delivering high-quality threads over a minimum length of 10 mm and up to 90 mm.Q: When should the machine be serviced or maintained?

A: Thanks to its low-maintenance design and centralized lubrication system, routine maintenance is minimal and can be scheduled based on usage intensity. Regular checks of lubrication, coolant levels, and surface cleaning will help sustain optimal performance and machine longevity.Q: Where can the WMW UPW 12.5.1 be installed?

A: This machine is suitable for industrial manufacturing environments such as fastener production facilities, exporting houses, and supply centers requiring high-volume thread rolling. Its vibration-absorbing base and dust-protected panels make it adaptable to various workshop conditions.Q: What process does the machine use for thread formation?

A: Utilizing cold forming thread rolling, the machine compresses the blank between precisely engineered roll dies to create uniform threads. The gear-driven system ensures synchronization and accuracy throughout the rolling cycle.Q: How does the safety system benefit operators?

A: With features like emergency stop, guard interlocks, and overload protection, the WMW UPW 12.5.1 prioritizes operator safety. The integrated safety systems prevent unintended operation and protect against mechanical hazards during thread rolling.Q: What are the primary benefits of using this machine?

A: Users benefit from high precision thread forming, efficient automatic feeding, rapid throughput (up to 600 pieces/hour), and robust safety features. Its durable cast iron construction, low noise (< 78 dB), and low maintenance design contribute to reliable, cost-effective production.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Miscellaneous Machines Category

Rusch Germany 250 mm Fully Automatic Bandsaw Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Operating Type : Other, Fully Automatic

Power Source : Other, Electric

Color : Grey & Yellow

Surface Treatment : Other, Powder Coated

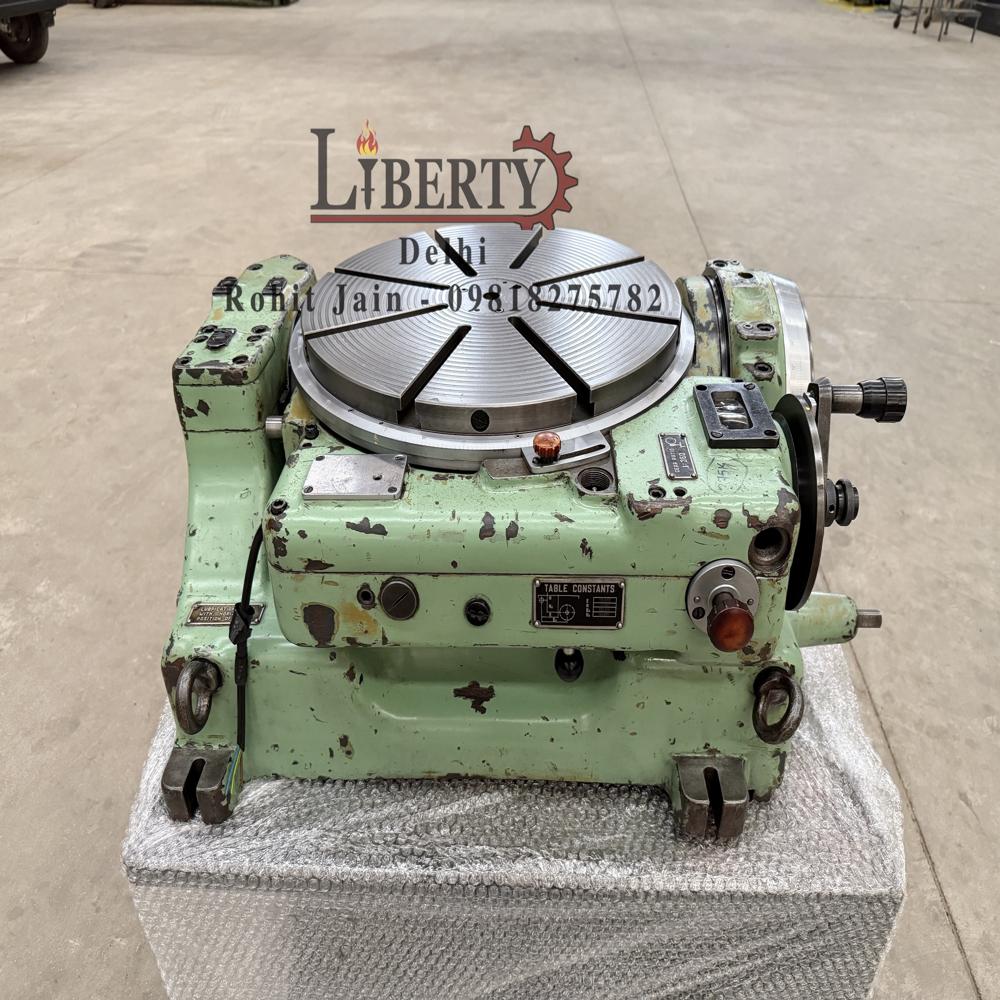

Skoda E20 Heavy Duty Rotary Table

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Operating Type : Other, Manual / Powered

Power Source : Other, Electric

Color : Industrial Grey

Surface Treatment : Other, Precision Ground Surface

Tool Presetter

Minimum Order Quantity : 1 Piece

Operating Type : Other, Manual Operation

Power Source : Electric, Other

Color : Gray

Surface Treatment : Painted Body, Other

Made in Italy 440 mm Diameter Tilting type Rotary Table

Price 100000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Operating Type : Semi Automatic

Power Source : Electricity

Surface Treatment : Coated

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry