Bevel Gear Testing And Lapping Machine

Bevel Gear Testing And Lapping Machine Specification

- Weight

- 950 kg

- Output

- Finished & tested bevel gears

- Manufacturing Year

- 2023

- Color

- Light Blue & White

- Voltage

- 415 V, 3 Phase

- Dimension (L*W*H)

- 1600 x 1200 x 1450 mm

- Used For

- Testing and lapping of bevel gears

- Capacity

- Gears up to 350 mm diameter

- Power

- 3 HP

- Condition

- New

- Machine Type

- Bevel Gear Testing And Lapping Machine

- Feature

- High precision testing, Smooth gear lapping, Durable construction

- Drive Type

- Belt driven

- Display Type

- Dial gauge & analog indicators

- Environment

- Suitable for workshop and industrial floors

- Safety Features

- Emergency stop switch, Gear guard cover

- Testing Accuracy

- Up to 0.01 mm

- Spindle Type

- Hardened & ground, high rigidity

- Main Spindle Bore

- 52 mm

- Lapping Speed Range

- 20 250 RPM

- Material Compatibility

- Steel, Alloy Steel, Cast Iron

- Gear Setup

- Adjustable mounting for various bevel gear sizes

- Max Gear Face Width

- 60 mm

- Control System

- Manual & semi-automatic operation

- Noise Level

- <75 dB(A)

- Coolant System

- Integrated lubricant and coolant flow

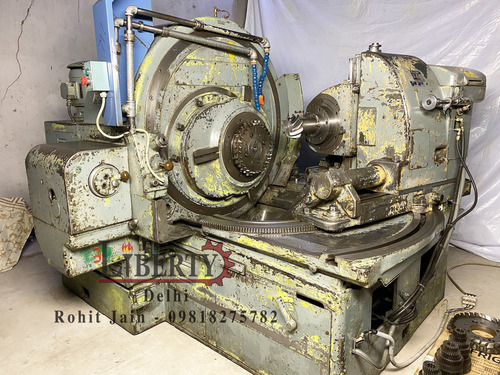

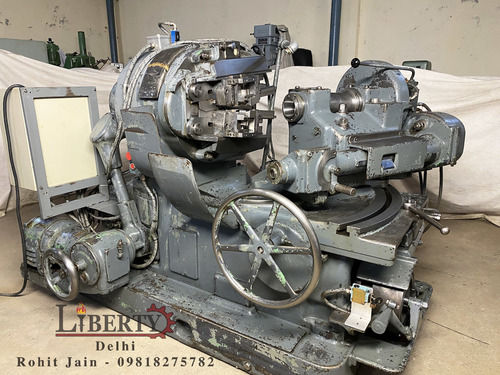

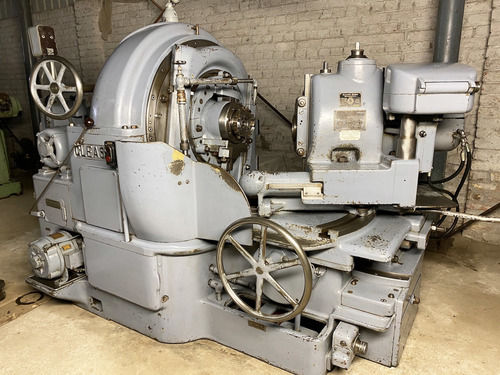

About Bevel Gear Testing And Lapping Machine

- Make - Gleason (USA)

- Model - Number 17

- Max. Diameter of Gear - 432 mm (17")

- Max. Distance from Center of Gear Spindle to nose of Pinion Spindle - 267 mm (10.5")

- Max. Distance from Center of Pinion Spindle to nose of Gear Spindle - 273 mm (10.75")

- Max. Offset of Gear Spindle above, or below, center of Pinion Spindle - 76 mm (3")

- Max. Drive Spindle Speeds - 1200 rpm

- Machine can work in Testing Mode as well as in Lapping Mode.

- Driven Head is Vertically Adjustable for Hypoid Gears.

- Operating Manual of the machine is available.

- Machine is in excellent working condition.

Efficient Gear Testing and Lapping

This machine streamlines the gear testing and lapping processes with its advanced manual and semi-automatic controls. The adjustable mounting accommodates various gear sizes, ensuring reliable adaptability for different applications. Its high-precision design aids in achieving accurate measurements, essential for quality assurance in gear manufacturing operations.

Robust Construction and Safety First

Engineered with a hardened and ground spindle for enhanced rigidity, the machine guarantees durability and stability during high-load operations. Safety is prioritized through features such as an emergency stop switch and a gear guard cover, protecting operators while maintaining optimal performance on workshop floors.

Integrated Cooling and Versatility in Operation

The built-in lubricant and coolant flow system minimizes heat generation and ensures smooth gear lapping. Coupled with adjustable mounting and compatibility with steel, alloy steel, and cast iron materials, the machine is versatile enough to handle various manufacturing and testing scenarios with ease.

FAQs of Bevel Gear Testing And Lapping Machine:

Q: How does the bevel gear testing and lapping machine ensure high precision in operations?

A: The machine offers testing accuracy up to 0.01 mm, supported by hardened and ground spindle construction and dial gauge/analog indicators for fine measurement and consistent quality.Q: What types of gears and materials can this machine accommodate?

A: It is designed for bevel gears up to 350 mm in diameter and 60 mm face width, compatible with steel, alloy steel, and cast iron, making it suitable for diverse industrial requirements.Q: When should I use the manual versus the semi-automatic operation modes?

A: Manual mode is ideal for custom, low-volume testing, while the semi-automatic mode is recommended for repetitive processes where speed and consistency are priorities.Q: Where can this machine be installed for optimal use?

A: It is well-suited for workshops and industrial floors, offering stable operation and low noise levels below 75 dB(A) for comfortable, continuous use in manufacturing environments.Q: What is the process for testing and lapping gears with this machine?

A: The gear is mounted and secured using the adjustable setup. The machine is then set to the desired operating mode and speed, with the lubricant/coolant system activated for smooth lapping. Measurement indicators assist in achieving precise results.Q: How does the integrated cooling system benefit gear processing?

A: The coolant and lubricant flow system reduces friction and excess heat, preventing gear damage and ensuring smoother lapping and extended component life.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bevel Gear Machines Category

Gleason No. 14 Straight Bevel Gear Generator

Price 14000 INR / Piece

Minimum Order Quantity : 1 Piece

Output : Bevel Gears

Weight : Undefined

Used For : Generating straight bevel gears

Color : Grey

Gleason No 26 Bevel Gear Generator

Price 2200 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Output : Bevel gears for automotive and industrial applications

Weight : Placeholder Weight Value

Used For : Gear manufacturing

Color : Grey

Gleason 12 Straight Bevel Gear Generator

Price 24000 INR / Piece

Minimum Order Quantity : 1 Piece

Output : Finished straight bevel gears

Weight : Approx. 2500 kg

Used For : Generating straight bevel gears

Color : Industrial Grey

Gleason No 16 Spiral Bevel Gear Generator

Price 6000 USD ($)

Minimum Order Quantity : 1 Piece

Output : Highprecision spiral bevel gears

Weight : Approx. 4,500 kg

Used For : Cutting and generating spiral bevel gears

Color : Grey

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry