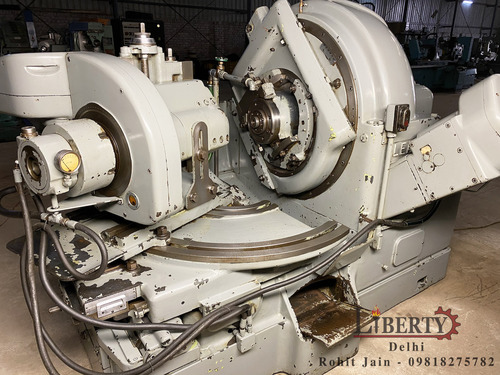

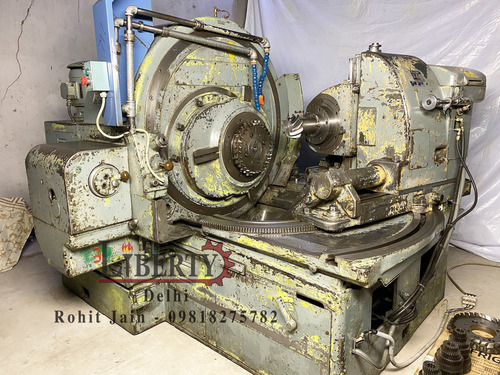

Gleason No 26 Bevel Gear Generator

Price 2200 USD ($)/ Piece

Gleason No 26 Bevel Gear Generator Specification

- Used For

- Gear manufacturing

- Capacity

- Placeholder Capacity Value

- Condition

- Used

- Color

- Grey

- Warranty

- No warranty (used condition)

- Power

- Placeholder Power Value

- Weight

- Placeholder Weight Value

- Dimension (L*W*H)

- Placeholder Dimensions (LxWxH)

- Voltage

- Placeholder Voltage Value

- Output

- Bevel gears for automotive and industrial applications

- Manufacturing Year

- Placeholder Year

- Machine Type

- Gear Generator

- Origin

- USA

- Feature

- Bevel Gear Generation

About Gleason No 26 Bevel Gear Generator

Technical Details

- Make - Gleason (USA)

- Model - No 26

- Type - Double-Cam

- Max. Gear Diameter - 838 mm

- Max. Cone Distance (30 degree and 18" cutter) - 419 mm

- Max./Min. Pitch Angle - 84Digree18' / 5Digree42'

- Extreme Ratio - 10 : 1

- Max. Face Width - 102 mm

- Max. Module - 16.9 module

- Weight of the Machine - 12 tons (approximately)

- Can work in Generation Mode as well as Format Mode.

- With Hydraulic Clamping of the Job.

- Complete with 3 x Cutter Bodies (12").

- Complete with a total of 79 pcs. of change gears.

- Operating Manual of the machine is available.

- Machine in excellent working condition.

- Video Link - https://youtu.be/Ki5YT05Ti8A

Efficient Bevel Gear Manufacturing

Specialized for bevel gear generation, the Gleason No 26 delivers accuracy and consistency in gear production. Its advanced mechanism enables it to produce gears tailored for both automotive and industrial sectors. Reliable performance and adaptability make it a popular choice among gear manufacturers globally.

Proven American Engineering

Originating from the United States, the Gleason No 26 Gear Generator showcases durable American engineering. Companies depend on its sturdy build and sophisticated technology to manufacture gears that meet high industry standards. Its reputation ensures continued demand in the used machinery market.

FAQs of Gleason No 26 Bevel Gear Generator:

Q: How is the Gleason No 26 Bevel Gear Generator utilized in gear production?

A: The machine is designed specifically for bevel gear generation, transforming raw gear blanks into precision-engineered bevel gears through a controlled and automated process.Q: What maintenance procedures are recommended for this used gear generator?

A: Routine maintenance includes regular inspection of moving parts, lubrication, cleaning, and timely replacement of worn components to maintain optimal performance and longevity.Q: When should a business consider adding the Gleason No 26 to their production line?

A: This gear generator is suitable for businesses expanding their bevel gear output, seeking cost efficiencies, or requiring equipment capable of manufacturing diverse gear specifications for automotive or industrial needs.Q: Where can this machine be integrated within a manufacturing facility?

A: It is best positioned alongside other machining equipment in gear manufacturing sections, allowing seamless workflow from raw material input to final gear output.Q: What is the main process facilitated by the Gleason No 26 Gear Generator?

A: The machine supports the complete generation of bevel gears, including cutting, shaping, and finishing, ensuring precise geometry and compatibility with various mechanical systems.Q: How does using a pre-owned Gleason No 26 benefit exporters and importers?

A: Choosing a used model provides significant cost savings while still delivering dependable performance, making it an attractive option for exporters, importers, and traders seeking efficiency in gear production.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bevel Gear Machines Category

Gleason No 16 Finisher Bevel Gear Generator

Price 6800 INR / Piece

Minimum Order Quantity : 1 Piece

Used For : Industrial gear production

Condition : Used

Color : Gray

Machine Type : Bevel Gear Generator

Gleason No. 14 Straight Bevel Coniflex Generator

Price 18000 INR / Piece

Minimum Order Quantity : 1 Piece

Used For : Precision gear cutting and generation of straight bevel gears

Condition : Used

Color : Industrial Grey

Machine Type : Straight Bevel Coniflex Gear Generator

Gleason 12-B Straight Bevel Gear Generator

Price 7000 INR / Piece

Minimum Order Quantity : 1 Piece

Used For : Manufacturing straight bevel gears

Condition : Used

Color : Green

Machine Type : Straight Bevel Gear Generator

Bevel Gear Testing And Lapping Machine

Price 6000 INR

Minimum Order Quantity : 1 Piece

Used For : Testing and lapping of bevel gears

Condition : New

Color : Light Blue & White

Machine Type : Bevel Gear Testing And Lapping Machine

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry