Breda Italy Automatic Drill Sharpening Machine

Price 100000.00 INR/ Piece

Breda Italy Automatic Drill Sharpening Machine Specification

- Voltage

- 220 Volt (v)

- Frequency

- 50 Hertz (HZ)

- Power Source

- Electricity

- Operating Type

- Semi Automatic

- Color

- gray

- Warranty

- 1 year

- Usage & Applications

- Industrial

Breda Italy Automatic Drill Sharpening Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Main Domestic Market

- All India

About Breda Italy Automatic Drill Sharpening Machine

Make - Breda (Italy)

Model - AFP 30

Drill Sharpening Capacity - Diameter 2 mm to 30 mm

Minimum & Maximum Vertex Angle - 80 degree to 180 degree

Stroke of Spindle Support - 70 mm

Grinding Wheel Diameter - 152 mm

Speed of Grinding Wheel - 3,750 rpm

- Machine can sharpen 2-point, 3-point and 4-point drills.

- With Automatic Feed Travel "Automatic Depth Adjustment".

- Complete with 2 sets of spare jaws, Coolant Tank and Pump.

- Operating Manual of the machine is available.

- Machine is in excellent working condition.

Video of The Machine -

Efficient Drill Sharpening for Industrial Needs

The Breda Italy Automatic Drill Sharpening Machine is tailored for robust industrial environments, delivering consistent results with minimal manual intervention. Its semi-automatic operation strikes a balance between user control and automation, ensuring that drills are sharpened efficiently and accurately each time.

Reliable Construction and International Standards

Engineered in Italy and finished in a sleek gray, this sharpening machine is built to last. It operates on a standard 220-volt electrical supply and conforms to established industrial frequency norms of 50 Hz, making it compatible in various settings worldwide.

FAQ's of Breda Italy Automatic Drill Sharpening Machine:

Q: How does the Breda Italy Automatic Drill Sharpening Machine operate?

A: This semi-automatic machine utilizes electricity to sharpen drills with precision. Users simply position the drill, choose the correct settings, and the machine takes over the sharpening process, streamlining it for consistent results.Q: What benefits does the semi-automatic design provide for users?

A: The semi-automatic design offers a blend of control and convenience, allowing users to manage sharpening parameters while benefiting from reduced manual labor and higher throughput in industrial operations.Q: When should drills be sharpened using this machine?

A: Drills should be sharpened whenever they become dull, show signs of chipping, or produce rough holes. Regular sharpening with this machine prolongs drill life and maintains drilling precision.Q: Where can the Breda Automatic Drill Sharpening Machine be used?

A: This machine is suitable for industrial environments such as manufacturing plants, maintenance workshops, and tool rooms, owing to its durable build and electrical compatibility.Q: What process does the machine follow to sharpen a drill bit?

A: The sharpening process involves securely mounting the drill, selecting the appropriate settings, and powering the machine. The automatic mechanism then grinds the drill to the correct angle and sharpness.Q: What warranty coverage comes with the machine?

A: The Breda Italy Automatic Drill Sharpening Machine includes a 1-year warranty, covering manufacturing defects and ensuring reliable support from the exporter, importer, manufacturer, supplier, or trader.Q: How does using this machine enhance efficiency in industrial settings?

A: Automating the sharpening process reduces downtime, minimizes errors, and ensures drills are consistently sharp. This leads to increased productivity and improved quality of drilled products.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Miscellaneous Machines Category

Gloria Super Italy Automatic Pitch Controlled Tapping Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Accuracy : 0.05 mm

Cooling System : Integrated coolant pump

Lubricating System : Centralized

Power : 0.75 kW

Kasto Germany 280 mm Capacity Semi-Automatic Bandsaw Machine

Price 100000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Accuracy : High cutting accuracy up to 0.1 mm

Cooling System : Integrated Coolant Pump

Lubricating System : Centralized lubrication system

Power : 2.2 kW

TOS HO-63 Heavy Duty Horizontal Shaper Machine

Price 100000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Accuracy : High, 0.01 mm

Cooling System : Inbuilt Coolant Pump

Lubricating System : Centralized Lubrication

Power : 7.5 HP

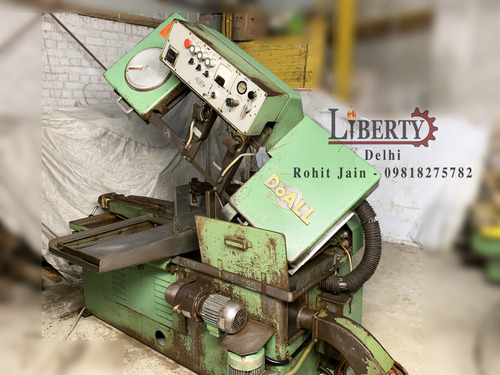

DoAll 325 mm Bandsaw Machine

Price 4000 USD ($)

Minimum Order Quantity : 1 Piece

Accuracy : High

Cooling System : Integrated Coolant System

Lubricating System : Manual lubrication

Power : Electric

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry