Caser Double Column VMC Machine

Price 100000 INR/ Piece

Caser Double Column VMC Machine Specification

- Product Type

- Double Column VMC Machine

- General Use

- Metal/Component Machining

- Material

- Cast Iron & Steel

- Type

- Vertical Machining Center

- Capacity

- Heavy Duty, 5 Ton Table Load

- Weight (kg)

- 11000 kg

- Computerized

- CNC

- Automatic

- Fully Automatic

- PLC Control

- Yes

- Power Source

- Electric

- Power Consumption

- 15 kW

- Rigidity

- High

- Voltage

- 380V

- Motor

- Servo Motor

- Table Size

- 2200 x 1200 mm

- Spindle Speed

- 8000 rpm

- Axial Choice

- X/Y/Z Axis

- Dimension (L*W*H)

- 3200 x 4200 x 3200 mm

- Feature

- Precision Machining, High Stability

- Color

- White & Blue

- Controller Brand

- Siemens/Fanuc

- Chip Conveyor

- Included

- Max Workpiece Height

- 850 mm

- Traverse (X/Y/Z)

- 2000 / 1200 / 900 mm

- Tool Magazine Capacity

- 24 Tools

- Coolant System

- Integrated

- Guideways

- Linear Motion Guideways

- Repeatability

- ±0.003 mm

- Ambient Temperature Range

- 0°C to 40°C

- Positioning Accuracy

- ±0.005 mm

- Spindle Motor Power

- 15 kW

- Power Phase

- Three Phase

- Lubrication

- Automatic Centralized

- Rapid Feed Rate

- 20 m/min

- Operator Interface

- Touchscreen Panel

Caser Double Column VMC Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Main Domestic Market

- All India

About Caser Double Column VMC Machine

Make - Caser (Italy)

Model - FF 60 CN

Table Size - 2150 mm x 1000 mm

Distance between Columns - 1700 mm

Vertical Cross-Rail Travel - 1000 mm

CNC Controller - ECS 4801

- Motors & Drives are all in excellent condition.

- Machine is is in excellent condition.

High Precision and Heavy-duty Performance

Casers Double Column VMC Machine stands out with its exceptional positioning accuracy (0.005 mm) and repeatability (0.003 mm), making it ideal for demanding metalworking applications. Supported by sturdy cast iron and steel construction and high rigidity, the machine delivers steadfast performance and smooth motion, even under heavy workloads of up to 5 tons. Its large work envelope accommodates sizable components, while linear motion guideways facilitate consistent precision across all axes.

Advanced Automation for Enhanced Productivity

Equipped with a 24-tool automatic magazine, automatic centralized lubrication, and a high-speed chip conveyor, the Caser VMC maximizes efficiency while reducing manual intervention. The integrated coolant system ensures optimal temperature management during machining, and a user-friendly touchscreen operator interface streamlines setup and operation. Choose between Siemens or Fanuc controllers for seamless integration into existing production lines.

Versatile Operation and Broad Applications

This vertical machining center excels in heavy-duty, high-precision metal and component machining in environments demanding reliability. Its robust CNC system, rapid feed rates, and flexible X/Y/Z travel accommodate diverse production requirements. Widely favored in manufacturing, exporting, and trading industries, the Caser Double Column VMC adapts easily to various working conditions, from prototyping to mass production, ensuring superior results every time.

FAQs of Caser Double Column VMC Machine:

Q: How does the Caser Double Column VMC Machine ensure precise machining?

A: The machine utilizes high-quality linear motion guideways, a robust 15 kW spindle motor, and servo motors to provide superior motion control. Its CNC system ensures a positioning accuracy of 0.005 mm and repeatability of 0.003 mm, achieving precise results even for intricate or repetitive tasks.Q: What are the main benefits of using an integrated coolant system and chip conveyor?

A: The integrated coolant system helps manage heat during machining, preserving tool life and ensuring dimensional accuracy. The chip conveyor efficiently removes metal shavings from the machining area, minimizing downtime and maintaining a safe and clean workspace.Q: When should I perform maintenance on this VMC machine?

A: Routine maintenance is streamlined with automatic centralized lubrication. However, periodic checkssuch as inspecting the coolant level, assessing guideways, and cleaning the chip conveyorare advised based on usage intensity. Adhering to manufacturer recommendations ensures optimal performance and longevity.Q: Where is this machine typically installed and used?

A: The Caser Double Column VMC is commonly installed in industrial manufacturing facilities, including those specializing in heavy-duty metal or component machining. Its size and capacity make it ideal for workshops requiring high throughput and reliability.Q: What process controls and operator interfaces are available?

A: Operators interact with the machine via an intuitive touchscreen panel. The system supports either Siemens or Fanuc controllers and is equipped with PLC controls for reliable automation, allowing for precise command over machining processes and facilitating easy integration into existing production workflows.Q: How can this machine accommodate heavy and large workpieces?

A: With a table size of 2200 x 1200 mm, a table load capacity of 5 tons, and a maximum workpiece height of 850 mm, the Caser VMC is engineered to securely handle sizable and heavy parts. Its robust construction and advanced servo motors maintain stability during heavy-duty operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in HMC & VMC - CNC Machining Centres Category

Bergonzi Double Column VMC Machine

Price 1100 USD ($) / Piece

Minimum Order Quantity : 1 Piece

PLC Control : Yes

Computerized : Yes

Automatic : Other, Fully Automatic

Power Source : Electric

Mecof CNC Bed Milling Machine

Price 33000 USD ($)

Minimum Order Quantity : 1 Piece

PLC Control : Yes

Computerized : Yes

Automatic : Yes

Power Source : Electric

Takumi V11A VMC Machine

Price 19400 USD ($)

Minimum Order Quantity : 1 Piece

PLC Control : Other, Available (Fanuc/Siemens/Mitsubishi options)

Computerized : Yes

Automatic : Yes

Power Source : Electric

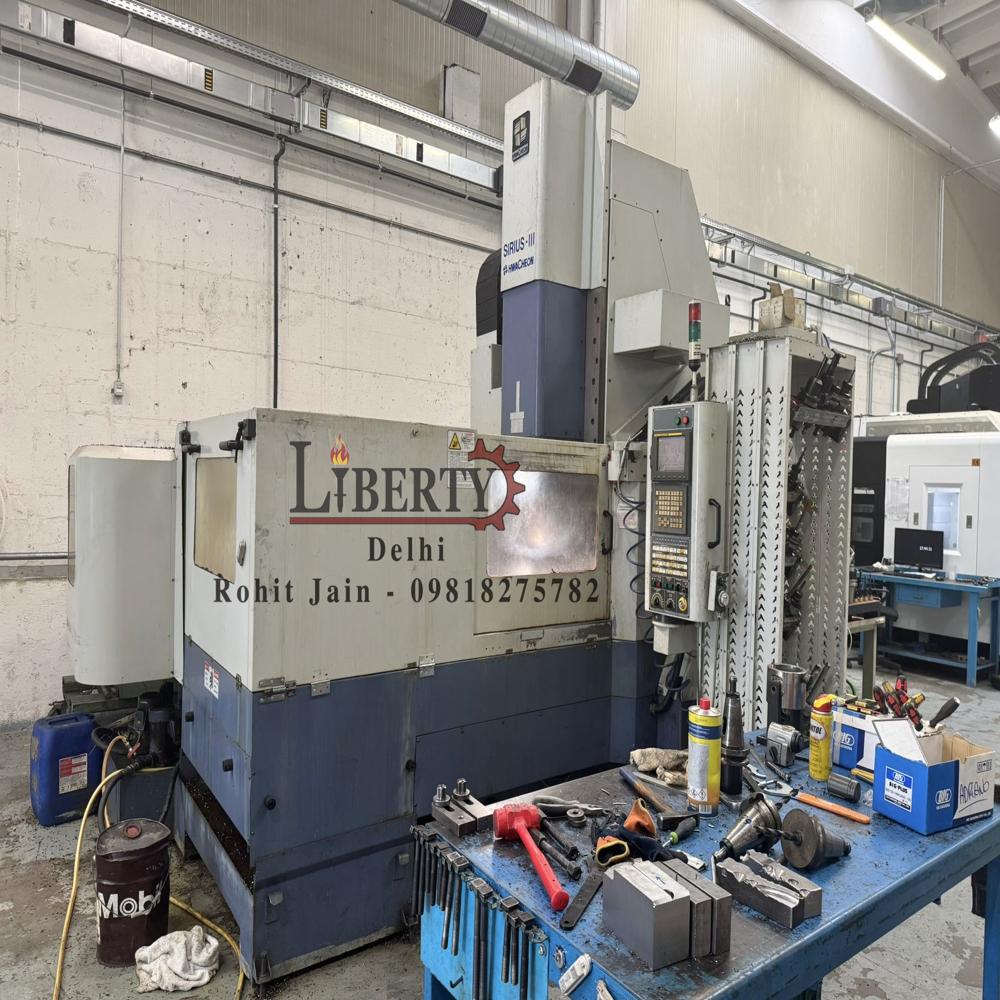

Hwacheon Korea Sirius-III Double Column Vertical Machining Center

Price 100000.0 INR / Unit

Minimum Order Quantity : 1 Unit

PLC Control : No

Computerized : No

Automatic : No

Power Source : Electric

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry