Takumi V11A VMC Machine

Takumi V11A VMC Machine Specification

- Product Type

- Vertical Machining Center (VMC)

- General Use

- Metal Cutting / Precision Engineering

- Material

- Cast Iron / Steel Components

- Type

- CNC Vertical Machining Center

- Capacity

- Max Workpiece Weight: 1000 kg

- Weight (kg)

- 8000 kg

- Computerized

- Yes

- Automatic

- Yes

- PLC Control

- Available (Fanuc/Siemens/Mitsubishi options)

- Bar Feeder

- No

- Power Source

- Electric

- Power Consumption

- 29 kVA

- Rigidity

- High rigidity, heavy cast-iron base

- Voltage

- 380V / 50Hz

- Motor

- Spindle Motor: 18.5/22 kW (Fanuc)

- Table Size

- 1200 x 600 mm

- Spindle Speed

- 12,000 rpm

- Axial Choice

- 3 Axis (X/Y/Z)

- Dimension (L*W*H)

- 3460 x 2630 x 2880 mm

- Feature

- High speed, precision machining, rigid structure

- Color

- Standard Grey/White

- Repeatability

- ±0.003 mm

- Machine Floor Area Required

- Around 9 m²

- Lubrication System

- Automatic Lubrication

- Tool Magazine Capacity

- 24 Tools (ATC)

- Max Cutting Feed Rate

- 12000 mm/min

- Air Pressure Requirement

- 6-8 kgf/cm²

- Input Power

- 25 kVA

- Coolant System

- Standard Integrated

- Control System

- FANUC / Siemens / Mitsubishi (optional)

- Max Rapid Traverse (X/Y/Z)

- 30/30/24 m/min

- Positioning Accuracy

- ±0.005 mm

- Spindle Taper

- BT40

- Tool Shank Type

- BT40

- Travel (X/Y/Z axis)

- 1100/600/600 mm

About Takumi V11A VMC Machine

Make - Takumi-Seiki (Taiwan)

- Model - V11A

- Table Size - 1350 mm x 510 mm

- Longitudinal Travel (X-Axis) - 1100 mm

- Cross Travel (Y-Axis) - 550 mm

- Vertical Travel (Z-Axis) - 650 mm

- CNC Controller - Fanuc OM-C (Alpha Series)

- Spindle Speeds - 60 rpm to 6000 rpm

- Spindle Taper - BT-40

- No. of Tools in Automatic Tool Changer (ATC) - 24 tools

- Table Rapid Travel Rate - 12 m/min

- Spindle Motor - 11 KW

- Year of Make - 1995

- Weight of the Machine - 7 Tons

- Equipped with 4th Axis Drive, cable etc.

- All Drives are Fanuc Alpha Series Drives.

- Complete with Spindle Oil Chiller, Step Down Transformer, etc.

- Machine is in excellent working condition.

Video Link - https://youtu.be/w3jt7VJ5hQY

Precision Engineering for Demanding Applications

With its high rigidity, heavy-duty cast-iron construction, and state-of-the-art control options, the Takumi V11A delivers remarkable accuracy, reliability, and efficiency for metal cutting and precision engineering purposes. The machines advanced technical design ensures stable operation, minimizing vibration and maximizing output quality even during intensive, high-speed processes.

Versatile and Powerful Machining Capabilities

The V11A offers a large working envelope (1100x600x600 mm travel, 1200x600 mm table) and rapid traverse rates (up to 30 m/min on X and Y axes), allowing for a broad range of workpieces and tasks. The integrated ATC with 24-tool capacity and BT40 spindle shank supports seamless, uninterrupted machining for various production needs.

FAQs of Takumi V11A VMC Machine:

Q: How is the Takumi V11A VMC machine used in precision metal cutting applications?

A: The Takumi V11A is utilized for high-precision machining tasks such as milling, drilling, and finishing metal components. Its advanced CNC controls and rigid construction allow for consistent, repeatable results, making it suitable for industries like aerospace, automotive, and precision engineering.Q: What features enhance the accuracy and repeatability of the Takumi V11A?

A: The machines robust cast-iron base, precision linear guideways, and automatic lubrication system contribute to its stable operation. Its positioning accuracy of 0.005 mm and repeatability of 0.003 mm ensure precise and consistent machining of complex workpieces.Q: When might I need to select between FANUC, Siemens, or Mitsubishi control systems?

A: Control system selection often depends on existing shop floor compatibility, operator familiarity, or customer requirements. The V11A offers flexibility to choose between FANUC, Siemens, or Mitsubishi controls, catering to various industry standards and user expertise.Q: Where should the Takumi V11A be installed for optimal performance?

A: For best results, the machine should be installed in a vibration-free, temperature-controlled environment with adequate space, as the required floor area is about 9 m. Access to a 380V/50Hz power supply and air pressure of 68 kgf/cm is also essential.Q: What is the process of changing tools with this machine?

A: The Takumi V11A features an automatic tool changer (ATC) that holds 24 tools with BT40 shank. Programming tool changes within the CNC software allows for automatic, fast swaps during machining cycles, reducing downtime and improving efficiency.Q: How does the integrated lubrication and coolant system benefit users?

A: Automatic lubrication and standard coolant systems ensure optimal component lifespan, reduce maintenance needs, and prevent overheating during prolonged or high-speed operations. This preserves machining precision and extends machine longevity.Q: What are the main advantages of choosing the Takumi V11A for manufacturing?

A: Key advantages include outstanding precision, high-speed capabilities, large work envelope, robust construction, and user-friendly CNC controls. These features combine to improve productivity, reduce cycle times, and enable machining of complex and heavy workpieces reliably.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in HMC & VMC - CNC Machining Centres Category

Bergonzi Double Column VMC Machine

Price 1100 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Automatic : Other, Fully Automatic

PLC Control : Yes

Computerized : Yes

Voltage : 380V/415V, 50/60 Hz

Caser Double Column VMC Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic : Other, Fully Automatic

PLC Control : Yes

Computerized : Other, CNC

Voltage : 380V

Mecof CNC Bed Milling Machine

Price 33000 USD ($)

Minimum Order Quantity : 1 Piece

Automatic : Yes

PLC Control : Yes

Computerized : Yes

Voltage : 380 V / 415 V

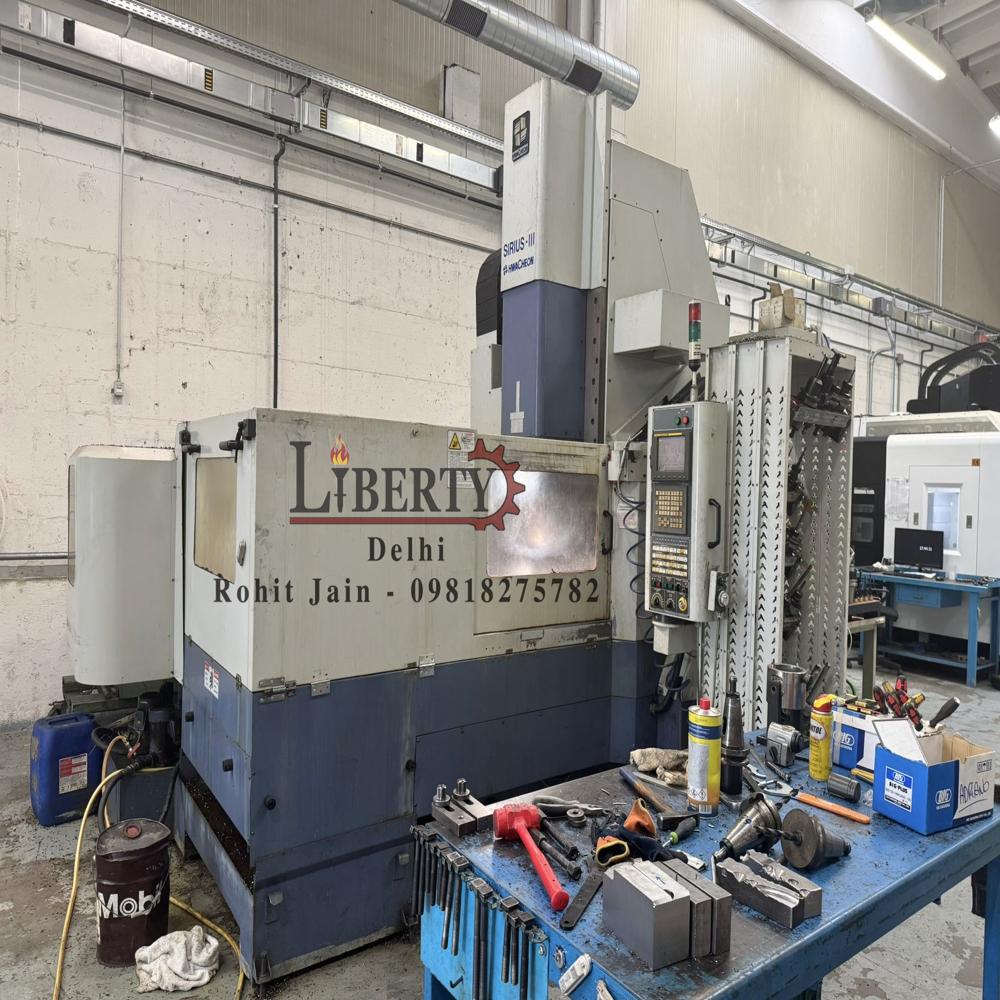

Hwacheon Korea Sirius-III Double Column Vertical Machining Center

Price 100000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : No

PLC Control : No

Computerized : No

Voltage : 110215 Volt (v)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry