Mecof CNC Bed Milling Machine

MOQ : 1 Piece

Mecof CNC Bed Milling Machine Specification

- Product Type

- CNC Bed Milling Machine

- General Use

- Milling, Drilling, Heavy Duty Industrial Manufacturing

- Material

- Cast Iron, Steel

- Type

- Automatic & CNC Controlled

- Capacity

- Large Part Handling

- Weight (kg)

- 13000

- Computerized

- Yes

- Automatic

- Yes

- PLC Control

- Yes

- Bar Feeder

- No

- Power Source

- Electric

- Power Consumption

- High Precision, Industrial Grade

- Rigidity

- Heavy Duty Construction

- Voltage

- 380 V / 415 V

- Motor

- Powerful AC Spindle Motor

- Table Size

- 3000 mm x 1000 mm

- Spindle Speed

- Up to 4000 RPM

- Axial Choice

- X, Y, Z axes

- Dimension (L*W*H)

- Approx. 5200 mm x 3200 mm x 2800 mm

- Feature

- High Accuracy, Robust Structure, Large Working Table

- Color

- White & Blue

- Machine Structure

- Box-shaped Bed, High Stability

- Tool Changer

- Automatic, 20 Positions

- Table Load Capacity

- 6000 kg

- Axis Guideways

- Hardened & Ground

- Positioning Accuracy

- ± 0.01 mm

- Control System

- Siemens/Fanuc CNC System

- Travel (X/Y/Z)

- 2500 mm / 1200 mm / 1000 mm

- Spindle Taper

- ISO 50

- Repeatability

- ± 0.005 mm

- Rapid Feed

- Up to 15 m/min

- Lubrication

- Automatic Lubrication System

- Coolant System

- Integrated

About Mecof CNC Bed Milling Machine

Seize remarkable savings with the famed Mecof CNC Bed Milling Machineending soon! Order today to secure this magnificent, commanding industrial marvel suitable for heavy-duty milling, drilling, and manufacturing. Featuring travel dimensions (X/Y/Z): 2500 mm / 1200 mm / 1000 mm, a massive 6000 kg table load, and robust structure for absolute stability. With automatic 20-position tool changer, exceptional accuracy ( 0.01 mm), integrated coolant, powerful Siemens/Fanuc controls, and rapid feeds up to 15 m/min, this elite, computerized solution ensures efficiency and precision for demanding applications. High-capacity, heavy-duty, and engineered in Italy.

Versatile Application & Exceptional Control

The Mecof CNC Bed Milling Machine excels in industrial environments where precision and reliability are paramount. Its large working table and advanced CNC control system suit both general usage such as routine milling and specific heavy-duty industrial manufacturing needs. With automated and computerized operation, the machine is engineered for consistent performance, handling cast iron and steel parts over extensive dimensions for demanding projects across manufacturing sites worldwide.

Sample Policy, Export Markets & Delivery Features

Mecof offers a sample policy at the lowest price with favorable freight options. Each order is shipped from the main FOB port in Italy, ensuring secure and timely deliveries. The machine caters to both international and domestic markets, making it an ideal choice for exporters, importers, manufacturers, suppliers, and traders. Focused on robust domestic and global supply chains, Mecof ensures competitive pricing and reliable delivery to the main export markets around the world.

Versatile Application & Exceptional Control

The Mecof CNC Bed Milling Machine excels in industrial environments where precision and reliability are paramount. Its large working table and advanced CNC control system suit both general usage such as routine milling and specific heavy-duty industrial manufacturing needs. With automated and computerized operation, the machine is engineered for consistent performance, handling cast iron and steel parts over extensive dimensions for demanding projects across manufacturing sites worldwide.

Sample Policy, Export Markets & Delivery Features

Mecof offers a sample policy at the lowest price with favorable freight options. Each order is shipped from the main FOB port in Italy, ensuring secure and timely deliveries. The machine caters to both international and domestic markets, making it an ideal choice for exporters, importers, manufacturers, suppliers, and traders. Focused on robust domestic and global supply chains, Mecof ensures competitive pricing and reliable delivery to the main export markets around the world.

FAQs of Mecof CNC Bed Milling Machine:

Q: How does the Mecof CNC Bed Milling Machine enhance industrial machining tasks?

A: The Mecof CNC Bed Milling Machine offers high positioning accuracy, repeatability, and automated tool changes, making it exceptionally efficient for milling and drilling large, heavy parts in industrial manufacturing environments.Q: What specific materials can be processed using this machine?

A: This machine is designed to handle cast iron and steel, providing robust performance and precision for heavy-duty components common in industrial production.Q: Where is the Mecof CNC Bed Milling Machine manufactured and exported from?

A: The machine is manufactured in Italy and shipped to various international and domestic markets via a reliable FOB port, ensuring efficient and secure delivery worldwide.Q: When should clients place orders to avail savings and fast delivery?

A: Clients are encouraged to order today, as the special savings are ending soon. Early ordering secures the best pricing and faster access to high-demand models.Q: What are the benefits of the advanced control system options?

A: The Siemens/Fanuc CNC control systems enable superior automation, high precision, and user-friendly operation, streamlining complex milling and drilling processes for optimal results.Q: How does the automatic lubrication and coolant system contribute to machine maintenance and longevity?

A: The integrated lubrication and coolant systems reduce wear, ensure stable operation, enhance accuracy, and prolong component lifespan, limiting downtime and optimizing productivity.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in HMC & VMC - CNC Machining Centres Category

Mori Seiki MV-65 Vertical Machining Center

Price 40000 INR / Piece

Minimum Order Quantity : 1 Piece

Computerized : Yes

PLC Control : Other, Fanuc CNC Control

Automatic : Yes

Color : Other, Machine Grey

Kia 500 x 500 Horizontal Machining Center

Price 50000 INR / Piece

Minimum Order Quantity : 1 Piece

Computerized : Yes

PLC Control : Other, Available

Automatic : Other, Fully Automatic

Color : Other, White & Blue

Caser Double Column VMC Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Computerized : Other, CNC

PLC Control : Yes

Automatic : Other, Fully Automatic

Color : Other, White & Blue

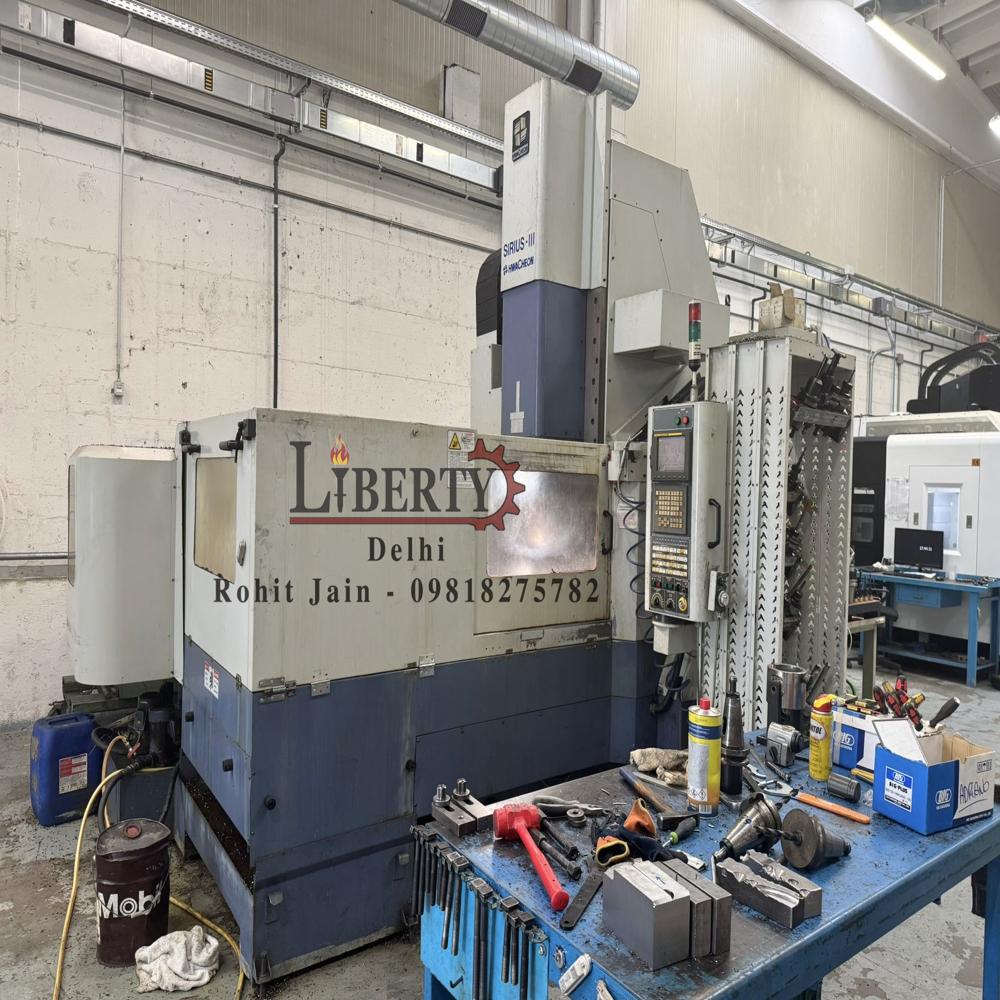

Hwacheon Korea Sirius-III Double Column Vertical Machining Center

Price 100000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : No

PLC Control : No

Automatic : No

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry