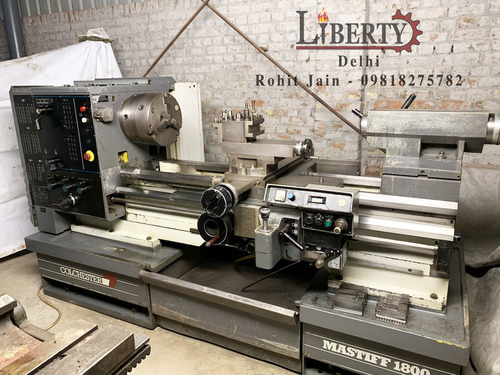

Medium Duty Colchester Mastiff Lathe Machine

Medium Duty Colchester Mastiff Lathe Machine Specification

- Product Type

- Medium Duty Lathe Machine

- Material

- Cast Iron Body and Hardened Steel Components

- Cutting Thickness

- Up to 15 mm (Material Dependent)

- Cutting Speed

- 402000 RPM

- CNC Or Not

- Conventional (Not CNC)

- Automatic Grade

- Manual

- Control System

- Manual

- Max. Swing Diameter

- 400 mm

- Voltage

- 415V, 50Hz, 3 Phase

- Weight (kg)

- Approx. 1800 kg

- Dimension (L*W*H)

- Approx. 3100 mm x 1100 mm x 1400 mm

- Capacity

- Bed Length 20003000 mm

- Feature

- All-geared Headstock, Induction Hardened Bed, High Precision

- Color

- Standard Industrial Grey

- Spindle Nose

- Camlock

- Surface Finish Accuracy

- Up to 0.015 mm

- Distance Between Centers

- 1500 mm 2000 mm

- Number of Spindle Speeds

- 8 to 16 Steps

- Lubrication

- Centralized Lubrication System

- Cross Slide Travel

- 285 mm

- Longitudinal Feed Range

- 0.05 to 2 mm/rev

- Power Required

- 35 HP Electric Motor

- Chuck Size

- 250 mm (3 or 4 Jaw)

- Spindle Bore

- 52 mm

- Bed Width

- 325 mm

- Lead Screw Diameter

- 32 mm

- Thread Cutting Range

- Metric and Imperial (Variety of Pitches)

- Headstock Type

- All-geared

- Application

- Turning, Facing, Threading, Parting, Drilling

- Tailstock Quill Travel

- 200 mm

About Medium Duty Colchester Mastiff Lathe Machine

Make - Colchester (England)

Model - Mastiff VS 1800

Center Height - 275 mm

Max. Length of Job - 1100 mm

Max. Diameter of Job over Bed - 550 mm

Max. Diameter of Job over Cross-Slide - 370 mm

Bed Width - 400 mm

Spindle Speeds - 18 rpm to 1800 rpm

Spindle Bore - 90 mm

Chuck Diameter - 310 mm

Max. Diameter of Job in Gap - 830 mm

Year of Make - 1996

- Motorized Rapid Travel of Carriage & Cross-Slide.

- Equipped with Drive for Spindle Motor for continuously variable spindle speeds.

- Latest series of conventional Lathes manufactured by Colchester company.

- Machine is in excellent working condition.

Video Link -https://youtu.be/UcPEZOjme84

High-Precision Machining

Achieve superior accuracy with the Mastiff lathes induction-hardened bed and all-geared headstock. The machine supports a surface finish up to 0.015 mm, catering to demanding precision requirements in engineering and fabrication industries. Its robust feed ranges and variable spindle speeds allow for meticulous adjustments, ensuring consistent results.

Versatile Operational Capability

Designed for a wide range of applications, this lathe handles multiple machining processes such as turning, facing, threading (metric and imperial), parting, and drilling. The variable spindle speeds (402000 RPM) and adaptable chuck (250 mm, 3 or 4 jaw) provide flexibility when working with different materials and dimensions.

Reliable Construction & Efficient Use

With a cast iron body and hardened steel components, the Colchester Mastiff ensures strength and longevity. The centralized lubrication system aids maintenance and performance, while its manual control system enables skilled operators to manage complex tasks with ease. The standard industrial grey finish adds a layer of durability and professional aesthetics.

FAQs of Medium Duty Colchester Mastiff Lathe Machine:

Q: How does the all-geared headstock benefit the Colchester Mastiff Lathe Machine?

A: The all-geared headstock enables stable power transmission, smoother speed changes, and higher reliability during machining operations, resulting in enhanced performance and extended component life.Q: What types of machining processes can this lathe perform?

A: This lathe is suitable for turning, facing, threading (both metric and imperial), parting, and drilling, making it ideal for varied tasks in manufacturing, metalworking, and repair workshops.Q: When should I use the different spindle speeds available on the machine?

A: Spindle speeds range between 40 and 2000 RPM across 8 to 16 steps. Select lower speeds for heavy or thick materials and higher speeds for finer cuts and smaller diameters, optimizing both tool life and surface finish.Q: Where is this lathe machine typically used?

A: The Colchester Mastiff Lathe is commonly used in engineering facilities, manufacturing units, repair shops, and training centers in the United Kingdom and internationally due to its robust construction and operational flexibility.Q: What is the process for adjusting the longitudinal feed and thread cutting range?

A: Longitudinal feed rate is adjustable from 0.05 to 2 mm/rev using manual controls. For thread cutting, the machine supports a variety of metric and imperial pitches, allowing precise selection for different threading tasks.Q: How does the centralized lubrication system enhance machine usage?

A: This system ensures efficient and uniform lubrication of critical components, reducing wear, simplifying maintenance, and extending service intervals, thereby improving overall machine reliability and lifespan.Q: What are the key advantages of the machines construction and control system?

A: The lathe features a cast iron body and hardened steel parts for durability, manual controls for hands-on operation, and an induction-hardened bed for precision. These aspects combine to provide high accuracy and reliability in conventional machining tasks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Lathe Machine Category

Ateliers Titan 3000 mm Lathe Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 415 V / 3 Phase / 50 Hz

Control System : Other, Manual with Mechanical Controls

Automatic Grade : Other, SemiAutomatic

CNC Or Not : Other, Conventional / Manual

TOS SU63A 1250 mm Heavy Duty Lathe Machine

Price 55000 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 415 V

Control System : Other, Manual

Automatic Grade : Other, Manual

CNC Or Not : Other, Conventional / Manual

Colchester England 2000 mm Length Gap-Bed Lathe Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 415 V, 3 phase

Control System : Other, Geared manual controls

Automatic Grade : Other, Manual

CNC Or Not : Other, No, Manual lathe

TOS Czech Republic SUI-50 Lathe Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 415 V / 3 Phase / 50 Hz

Control System : Other, Manual

Automatic Grade : Other, SemiAutomatic

CNC Or Not : Other, No (Conventional)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry