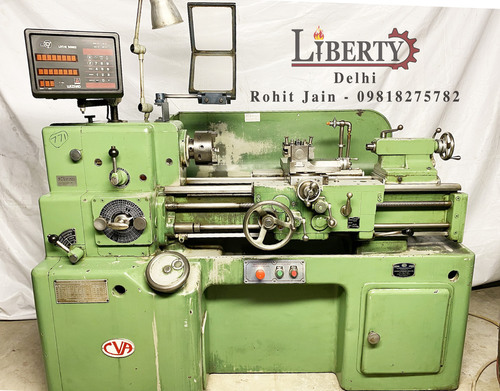

CVA Precision Tool Room Lathe

Price 2800 USD ($)/ Piece

CVA Precision Tool Room Lathe Specification

- Product Type

- Tool Room Precision Lathe

- Material

- Cast Iron, Hardened and Ground Bed

- Cutting Thickness

- Up to 10 mm (depending on material)

- Cutting Speed

- Variable, up to 2000 RPM

- CNC Or Not

- Not CNC, Manual Operation

- Automatic Grade

- Manual

- Control System

- Manual

- Max. Swing Diameter

- 250 mm

- Voltage

- 415 V, 3 Phase

- Weight (kg)

- Approx 1200 kg

- Dimension (L*W*H)

- 1500 x 800 x 1200 mm (approx)

- Capacity

- Suitable for precision tool room operations

- Feature

- High Precision, Hardened Bed, Accurate Feed Mechanism

- Color

- Green

- Distance Between Centers

- 900 mm

- Coolant System

- Yes, Fitted with Pump

- Spindle Speeds

- Variable, 12 Steps

- Thread Cutting Range

- Whitworth 4-56 TPI, Metric 0.45-7 mm

- Longitudinal Feed Range

- 0.02-0.45 mm/rev

- Chuck Size

- 160 mm (3 Jaw)

- Power Consumption

- 2 HP Main Motor

- Tailstock Quill Travel

- 120 mm

- Spindle Bore

- 35 mm

- Bed Width

- 180 mm

- Cross Slide Travel

- 155 mm

About CVA Precision Tool Room Lathe

CVA Precision Tool Room Lathe

- Make - CVA (England)

- Model - 1A

- Center Height - 160 mm

- Max. Length of Job - 750 mm

- Max. Diameter over Bed - 320 mm

- Max. Diameter over Cross-Slide - 160 mm

- Bed Width - 265 mm

- Spindle Speeds - 29 rpm to 2220 rpm

- Spindle Bore - 35 mm

- Chuck Diameter - 155 mm

- - Machine is equipped with a 2-Axis DRO.

- - Complete with Faceplate, Collets, Change Gears etc.

- - Machine is in excellent working condition.

High Precision for Demanding Tasks

This CVA lathe is engineered for tool room accuracy, boasting a hardened, ground bed and meticulous feed mechanisms. Its 12-step variable spindle speed system optimizes machining for a broad spectrum of materials and tasks, ensuring reliable results with every use.

Flexible Thread Cutting Capabilities

Easily switch between Whitworth (4-56 TPI) and metric (0.45-7 mm) threads, providing versatile threading solutions to meet diverse industrial standards. This adaptability makes it suitable for manufacturers requiring frequent thread configuration changes.

Built for Durability and Longevity

Manufactured from high-quality cast iron and equipped with a hardened bed, the lathe ensures superior stability and resistance to wear. The integrated coolant system enhances tool life while supporting extended operation in precision environments.

FAQs of CVA Precision Tool Room Lathe:

Q: How is the distance between centers of 900 mm beneficial in tool room operations?

A: A 900 mm distance between centers allows for machining longer workpieces, providing versatility for precision tool room projects that demand extended material handling and support.Q: What types of threads can the CVA Precision Lathe cut?

A: It can cut both Whitworth threads ranging from 4-56 TPI and metric threads from 0.45 to 7 mm, ensuring compatibility with a variety of industrial and engineering requirements.Q: When is manual operation preferred over CNC for this lathe?

A: Manual operation is ideal for applications where hands-on precision, flexibility, and intricate adjustments are required, making it highly suitable for custom work and smaller batches in a tool room setting.Q: Where can this lathe be installed for optimal usage?

A: Best suited for precision tool rooms, workshops, and manufacturing facilities requiring high accuracy and reliable performance in the United Kingdom and beyond.Q: What is the process for changing spindle speeds on the lathe?

A: Spindle speeds are adjusted manually through a 12-step variable system, providing seamless adaptation to different materials and cutting requirements for improved machining efficiency.Q: How does the coolant system contribute to the lathes performance?

A: Equipped with a fitted pump, the coolant system reduces heat buildup, protects tooling, and promotes consistent cutting quality, crucial for maintaining precision during extended machining operations.Q: What are the benefits of the hardened and ground bed featured in this model?

A: The hardened and ground bed offers enhanced durability and precision, ensuring the machine maintains alignment and accuracy over time, even under rigorous use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Lathe Machine Category

Ateliers Titan 3000 mm Lathe Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Cast Iron Body, Hardened Steel Bed

CNC Or Not : Other, Conventional / Manual

Weight (kg) : Approx. 3500 kg

Cutting Thickness : Up to 45 mm

XYZ England Tool Room Lathe Machine

Price 35000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : HighGrade Cast Iron

CNC Or Not : Other, No, Manual Operation

Weight (kg) : 1250 kg

Cutting Thickness : Up to 20 mm

PPL Italy 3000 mm Lathe Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Cast Iron structure, Hardened steel components

CNC Or Not : Other, Conventional (Not CNC)

Weight (kg) : 4800 kg

Cutting Thickness : Up to 35 mm

H. Ernault Somua Cholet 550 Gap-Bed Lathe Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : High Grade Cast Iron

CNC Or Not : Other, No (Manual Lathe)

Weight (kg) : Approx. 3300 kg

Cutting Thickness : Up to 12 mm

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry