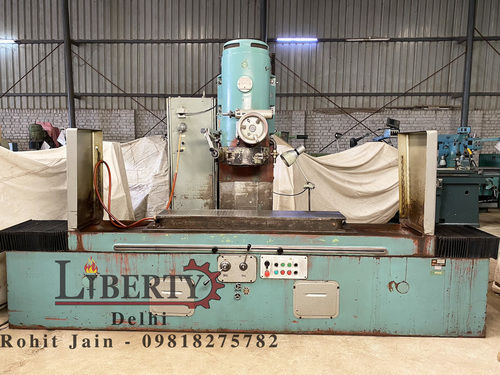

F. Cozzi 400 mm x 900 mm Vertical Cup Grinder

F. Cozzi 400 mm x 900 mm Vertical Cup Grinder Specification

- Rotation

- Clockwise

- Model

- F. Cozzi 400 mm x 900 mm Vertical Cup Grinder

- Product Type

- Vertical Cup Grinder

- General Use

- Vertical surface grinding operations for industrial and workshop applications

- Material

- Cast Iron, Steel

- Type

- Vertical Surface Grinder

- Capacity

- Suitable for medium to heavy duty grinding

- Weight (kg)

- Approx. 3500 kg

- Computerized

- No

- Automatic

- No

- CNC Or Not

- No

- Control System

- Manual

- Table Size

- 400 mm x 900 mm

- Table Slide Way

- V and flat type

- Magnetic Chuck Size

- 400 mm x 900 mm

- Grinding Wheel Size

- 400 mm diameter

- Grinding Wheel Speed

- 1450 RPM

- Grinding Length

- 900 mm

- Floor Space

- Approx. 2200 mm x 1700 mm

- Fuel Tank Capacity

- N/A (electric powered)

- Spindle Speed

- 1450 RPM

- Power

- 7.5 HP

- Voltage

- 415 V, 3 Phase

- Dimension (L*W*H)

- Approx. 2200 mm x 1700 mm x 2300 mm

- Feature

- Heavy-duty construction, precise surface finish, magnetic chuck

- Color

- Standard industrial grey

- Lubrication

- Centralized lubrication system

- Coolant System

- Built-in coolant tank with pump

- Working Speed

- Variable, up to 1450 RPM

- Max. Grinding Height

- 400 mm

- Chuck Type

- Electromagnetic

- Surface Finish Accuracy

- Up to 0.002 mm

- Table Movement

- Precision hand-wheel operated for longitudinal and cross feed

- Safety Features

- Overload protection, emergency stop

- Noise Level

- Less than 75 dB

- Bearings

- Precision anti-friction bearings on spindle

- Wheel Head Traverse

- Hydraulically operated vertical movement

- Operator Panel

- Integrated, ergonomic design

- Motor Power

- 7.5 kW main motor

- Machine Bed

- Heavy cast structure for vibration dampening

About F. Cozzi 400 mm x 900 mm Vertical Cup Grinder

Make - F. Cozzi (Italy)

Max. Job Grinding Size - 400 mm x 900 mm

Magnet Size - 250 mm x 800 mm

Segmented Wheel Cup Diameter - 300 mm

No. of Segmented Wheels - 8 pcs.

Cross Travel (Y Axis) of Table - 110 mm

Longitudinal Travel - 950 mm

Type - Motorized ; Mechanical.

- Lot's of Spare Grinding Wheels with the Machine.

- Coolant Tank & Pump is inside the machine.

- Machine is in excellent working condition.

Video link - https://youtu.be/wTBb18iqhzE

Precision Surface Grinding Redefined

Achieve unmatched accuracy with the F. Cozzi Vertical Cup Grinder, designed to deliver a superior surface finish up to 0.002 mm. The magnetic chuck holds materials firmly, while the heavy cast structure maintains stability and minimizes vibration, ensuring each project is completed to the highest standard.

Robust Build and Enhanced Safety

Built from durable cast iron and steel, this grinder weighs approx. 3500 kg, providing sturdiness for demanding industrial operations. Integrated features such as overload protection, emergency stop, and centralized lubrication not only safeguard the operator but also increase machine lifespan, making it a reliable choice for workshops.

FAQs of F. Cozzi 400 mm x 900 mm Vertical Cup Grinder:

Q: How does the hydraulically operated wheel head movement improve grinding performance?

A: The hydraulically operated vertical movement of the wheel head ensures smooth and consistent adjustment, enabling precise control over grinding depth and enhancing the overall accuracy and quality of the finished surface.Q: What materials can be processed on the F. Cozzi Vertical Cup Grinder?

A: This vertical surface grinder is suitable for medium to heavy-duty grinding of various workpieces, including cast iron and steel, making it versatile for industrial and workshop use.Q: When should I use the electromagnetic chuck feature during operation?

A: The electromagnetic chuck should be engaged when you need secure, stable holding of the workpiece during grinding, especially for operations requiring high precision and safety.Q: Where is the built-in coolant system located and how does it benefit the process?

A: The built-in coolant tank and pump are integrated into the machines body, delivering efficient cooling directly to the grinding area. This helps to prevent thermal damage, maintain accuracy, and extend the grinding wheels service life.Q: What safety features are incorporated to protect operators?

A: Key safety features include overload protection and an emergency stop function, both designed to safeguard operators from accidental incidents and prevent machine damage during heavy-duty operations.Q: How do I achieve high surface finish accuracy with this grinder?

A: Utilize the precision hand-wheel for fine table adjustments, operate with the correct grinding wheel speed, and ensure the coolant system is active. These combined features help deliver surface finish accuracies up to 0.002 mm.Q: What are the benefits of the centralized lubrication system?

A: The centralized lubrication system distributes oil efficiently to critical moving components, reducing wear and maintenance requirements and ensuring smoother operation for prolonged machine reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Surface Grinder Category

Jotes 300 mm x 1000 mm Surface Grinder Machine

Price 80000 INR / Piece

Minimum Order Quantity : 1 Piece

Grinding Length : 1000 mm

Capacity : Large batch grinding

Automatic : No

Power : 7.5 kW

Alpa 200 mm x 450 mm Surface Grinding Machine

Price 45000 INR / Piece

Minimum Order Quantity : 1 Piece

Grinding Length : 450 mm

Capacity : Heavy Duty

Automatic : Other, SemiAutomatic

Power : 1.5 HP

Jones & Shipman 540AP High Precision Surface Grinding Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Grinding Length : 18 (457 mm)

Capacity : Heavy Duty / Medium Batch Surface Grinding

Automatic : Other, SemiAutomatic

Power : 2 HP

MAS BPV 300 x 1500 Vertical Surface Grinder

Price 33000 INR / Piece

Minimum Order Quantity : 1 Piece

Grinding Length : 1500 mm

Capacity : 300 x 1500 mm

Automatic : No

Power : 7.5 HP

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry