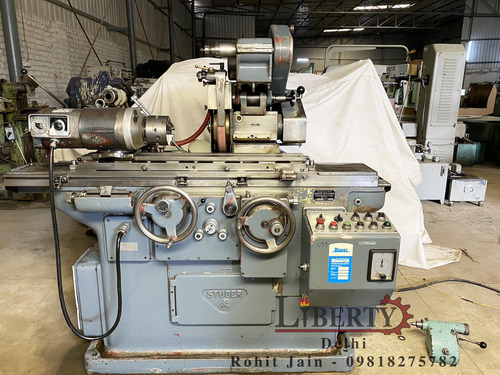

Fortuna Germany 1500 mm Cylindrical Grinder Machine

Price 100000 INR/ Piece

Fortuna Germany 1500 mm Cylindrical Grinder Machine Specification

- Product Type

- Cylindrical Grinder Machine

- General Use

- Industrial Grinding Operations

- Material

- Cast Iron with Hardened Steel Components

- Type

- Universal Cylindrical Grinder

- Capacity

- 1500 mm

- Weight (kg)

- Approx. 3500 kg

- Computerized

- No

- Automatic

- No

- Control System

- Manual

- Drive Type

- Electric Motor Driven

- Grinding Diameter

- Max. 350 mm

- Grinding Length

- Max. 1500 mm

- Spindle Speed

- Variable, up to 1200 RPM

- Grinding Wheel Size

- 400 mm (Diameter)

- Voltage

- 415 V

- Dimension (L*W*H)

- 3450 mm x 1450 mm x 1550 mm

- Feature

- Precision Grinding, Robust Construction, High Accuracy

- Color

- Standard Machine Grey

- Max. Center Height

- 175 mm

- Wheelhead Feed

- Automatic & Manual

- Model

- Fortuna 1500 mm

- Lubrication System

- Automatic Lubrication

- Min. Center Height

- 135 mm

- Workpiece Length Supported

- Up to 1500 mm

- Tailstock

- Manual, Adjustable

- Coolant System

- Integrated

- Workhead Swivel

- Available

- Table Traverse

- Manual

Fortuna Germany 1500 mm Cylindrical Grinder Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Main Domestic Market

- All India

About Fortuna Germany 1500 mm Cylindrical Grinder Machine

Make - Fortuna (Germany)

Center Height - 225 mm

Max. Diameter of Job - 450 mm

Max. Length of Job - 1500 mm

Grinding Wheel Size - Diameter 500 mm x 75 mm Width

Work-Head Speed - 23 rpm to 265 rpm

Least Count - 2.5 Microns (0.0025 mm)

- Features like Delay, Auto-Cut, Plunge Grinding, etc.

- Features like Hydraulic Tail-Stock, Auto-Compensation etc.

- Complete with 2 x Job Steady, Wheel Dresser, etc.

- Complete with Coolant Filtration Unit, Coolant Tank and Pump.

- Machine is in excellent working condition.

Video of The Machine -

Precision Performance for Industrial Grinding

Engineered for versatility and high-accuracy, the Fortuna Germany 1500 mm Cylindrical Grinder meets the rigorous demands of modern industry. The combination of a sturdy cast iron structure and hardened steel elements guarantees lasting durability while maintaining tight tolerances. Automatic lubrication and integrated coolant systems support seamless operation, making it suitable for lengthy production cycles or single-batch jobs alike.

User-Friendly Manual Controls with Automatic Features

This universal grinder offers flexible operation with manual control enhanced by automatic features, including wheelhead feed and lubrication. The workhead swivel and adjustable tailstock accommodate complex grinding tasks, ensuring adaptability for a variety of workpieces and requirements. Its user-centric design makes it accessible for operators seeking both control and convenience.

FAQ's of Fortuna Germany 1500 mm Cylindrical Grinder Machine:

Q: How does the Fortuna 1500 mm Cylindrical Grinder enhance grinding accuracy?

A: The machine features a robust cast iron base, hardened steel components, and a precision spindle, all of which minimize vibration and ensure consistent, high-accuracy grinding results across a broad range of workpieces.Q: What is the process for adjusting the tailstock and workhead swivel?

A: The tailstock and workhead on this grinder are manually adjustable, allowing operators to set up the machine for various workpiece lengths and angles. Simply unlock their respective levers, position as required, and secure them before operation for optimal alignment.Q: When should the integrated coolant and automatic lubrication systems be used?

A: Both the coolant and lubrication systems function during each grinding session to maintain tool life, reduce heat, and ensure smooth machine operation, enhancing performance and extending the lifespan of both the grinder and workpieces.Q: Where can this cylindrical grinder be installed and operated?

A: Designed for industrial environments, the Fortuna 1500 mm Grinder can be used in manufacturing plants, workshops, or production units with an available 415 V electric power supply and adequate space (L3450 x W1450 x H1550 mm).Q: What materials and workpiece sizes can this machine support?

A: The grinder supports a maximum workpiece length of 1500 mm, center height between 135 mm and 175 mm, and can handle grinding up to 350 mm in diameter. Robust enough for various metals, its cast iron and steel construction ensures reliable operation with diverse work materials.Q: How does the manual and automatic feed system benefit users?

A: Operators can choose between manual and automatic wheelhead feed, allowing for precise adjustment during delicate tasks or efficient, repeatable movement during production jobs. This flexibility makes it suitable for both skilled machinists and high-throughput operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cylindrical Grinder Category

TOS BHU 32A/1000 Cylindrical Grinder

Price 11000 INR / Piece

Minimum Order Quantity : 1 Piece

Grinding Diameter : 320mm

Material : Metal, Other

Type : Other, Industrial

Drive Type : Electric

Studer RHU 500 Cylindrical Grinder

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Grinding Diameter : Max 200 mm

Material : Other, Cast Iron (Machine Base and Major Components)

Type : Other, Universal

Drive Type : Other, Belt Driven

TOS BU 16 Precision Universal Cylindrical Grinder

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Grinding Diameter : 2 mm to 160 mm

Material : Other, Cast Iron, Steel

Type : Other, Precision Grinding Machine

Drive Type : Electric

Studer Universal Cylindrical Grinder

Price 13500 INR / Piece

Minimum Order Quantity : 1 Piece

Grinding Diameter : 1 320 mm

Material : Other, Cast Iron, Steel

Type : Other, CNC or Conventional

Drive Type : Other, Electric Motor Driven

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry