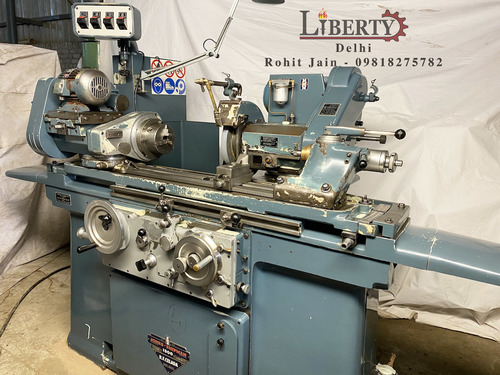

Fortuna Germany AFC-1000 Heavy Duty Cylindrical Grinding Machine

Price 100000.0 INR/ Piece

Fortuna Germany AFC-1000 Heavy Duty Cylindrical Grinding Machine Specification

- Product Type

- Fortuna (Germany) make Heavy Duty Cylindrical Grinding Machine in excellent working condition. The model of the machine is AFC-1000 and the Center Height is 185 mm. The machine is complete with 2 x Job Steady, many Wheel Dressers, spare Wheel & Flange, Coolant Tank, Pump & many other accessories. The machine has features like Delay, Automatic Depth Adjustment, Automatic Plunge Grinding, Automatic Compensation, Hydraulic Tail-Stock etc. The technical details are as follows -

- General Use

- Heavy Duty Cylindrical Grinding operations

- Material

- Cast Iron, Steel Components

- Type

- Cylindrical Grinding Machine

- Capacity

- Typically up to 1000 mm grinding length

- Weight (kg)

- Approx. 3500 kg

- Computerized

- No

- Automatic

- Yes

- Control System

- Hydraulic & PLC based

- Drive Type

- Electric motor driven

- Grinding Diameter

- Max. 320 mm

- Grinding Length

- 1000 mm

- Spindle Speed

- 32 to 3500 rpm (variable)

- Grinding Wheel Size

- 400 mm x 50 mm x 152 mm

- Voltage

- 415 V / 3 Phase / 50 Hz

- Dimension (L*W*H)

- Approx. 3150 mm x 1600 mm x 1500 mm

- Feature

- Delay, Automatic Depth Adjustment, Automatic Plunge Grinding, Automatic Compensation, Hydraulic Tail-Stock, Job Steady, Multiple Wheel Dressers, Spare Wheel & Flange, Coolant Tank & Pump, many accessories

- Color

- Industrial Grey

- Wheel Dressing System

- Multiple wheel dressers supplied

- Application Range

- Cylindrical external grinding operations

- Compensation

- Automatic grinding compensation

- Machine Condition

- Excellent running condition

- Tailstock

- Hydraulic

- Main Motor Power

- 7.5 kW

- Model

- AFC-1000

- Center Height

- 185 mm

- Coolant System

- Included with tank and pump

- Brand/Make

- Fortuna Germany

- Accessories Included

- 2 x Job Steady, Wheel Dressers, Spare Wheel & Flange, Coolant Tank, Pump

- Grinding Method

- Plunge grinding and traverse grinding

About Fortuna Germany AFC-1000 Heavy Duty Cylindrical Grinding Machine

Precision Engineering for Demanding Applications

Built in Italy and bearing the trusted Fortuna brand, the AFC-1000 offers heavy-duty performance and reliability for producers, exporters, and manufacturers. Its automatic functions, such as plunge grinding, compensation, and hydraulic tailstock adjustment, streamline complex operations and maintain high standards of accuracy. The machine's sturdy construction and comprehensive accessories package make it a versatile choice for grinding cast iron and steel components up to 1000 mm in length.

Comprehensive Accessory Suite for Enhanced Productivity

This machine comes equipped with two job steady rests, multiple wheel dressers, a spare wheel with flange, and a complete coolant system. These features ensure continuous, uninterrupted grinding operations and adapt to a wide range of cylindrical external grinding applications. The hydraulic-driven tailstock and PLC-based controls improve operator efficiency while reducing setup and changeover times, making the AFC-1000 ideal for workshops with varied production requirements.

FAQ's of Fortuna Germany AFC-1000 Heavy Duty Cylindrical Grinding Machine:

Q: How does the Fortuna Germany AFC-1000 ensure precise cylindrical grinding operations?

A: The AFC-1000 delivers precision through its PLC-based hydraulic control system, automatic grinding compensation, and multiple wheel dressers. These features maintain consistency during consecutive operations, whether performing plunge or traverse grinding, ensuring each component meets strict quality standards.Q: What types of materials and workpieces can be processed with this machine?

A: Designed for heavy-duty applications, the AFC-1000 can handle cast iron and steel components with a grinding diameter up to 320 mm and a maximum length of 1000 mm. Its robust construction makes it suitable for large, industrial workpieces.Q: When should you use plunge grinding versus traverse grinding on this machine?

A: Plunge grinding is ideal for components with complex, fixed-width surfaces, allowing for rapid material removal in one position. Traverse grinding is better suited for longer cylindrical surfaces, as the grinding wheel moves along the length of the workpiece to achieve uniformity.Q: What accessories are included with the Fortuna AFC-1000, and how do they benefit the user?

A: The machine includes two job steady rests, multiple wheel dressers, a spare grinding wheel with flange, a coolant tank with pump, and a hydraulic tailstock. These accessories support continuous operation, ease maintenance, and enable quick wheel changes, enhancing efficiency and adaptability.Q: Where can the AFC-1000 be installed, and what are its electrical requirements?

A: The AFC-1000 is suitable for heavy-duty industrial environments, including workshops and manufacturing plants. It operates on a 415V, 3-phase, 50Hz electric supply and requires adequate floor space, given its approximate dimensions of 3150 mm x 1600 mm x 1500 mm.Q: How does the coolant system contribute to the grinding process?

A: The included coolant tank and pump system dissipate heat generated during grinding, preserving the integrity of both the grinding wheel and workpiece. Efficient cooling reduces the risk of thermal damage, resulting in higher-quality finishes and longer tool life.Q: What are the key operational benefits of the Fortuna Germany AFC-1000 for manufacturers and suppliers?

A: Manufacturers benefit from the machine's automation, high production efficiency, and minimal downtime due to its comprehensive accessories. The hydraulic tailstock and PLC control reduce manual interventions, while the automatic compensation features ensure cost-effective, high-precision output for bulk production needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cylindrical Grinder Category

Jones Shipman 1077 High Precision Universal Cylindrical Grinder

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Other, Universal Cylindrical Grinder

Product Type : Jones Shipman 1077 High Precision Universal Cylindrical Grinder

Grinding Length : 600 mm (Maximum) approx.

Control System : Other, Manual with optional Hydraulic

Ribon RUR-1000 Universal Cylindrical Grinding Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Other, Manual

Product Type : Universal Cylindrical Grinding Machine

Grinding Length : 1000 mm

Control System : Other, Manual control handwheels

TOS BHU40A 1500 mm Length Universal Cylindrical Grinder

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Other, BHUA Series

Product Type : Universal Cylindrical Grinder

Grinding Length : 1500 mm

Control System : Other, Conventional

Jones & Shipman 1300 Universal Cylindrical Grinder

Price 30000 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Other, Horizontal

Product Type : Universal Cylindrical Grinder

Grinding Length : 685 mm

Control System : Other, Manual Mechanical

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry