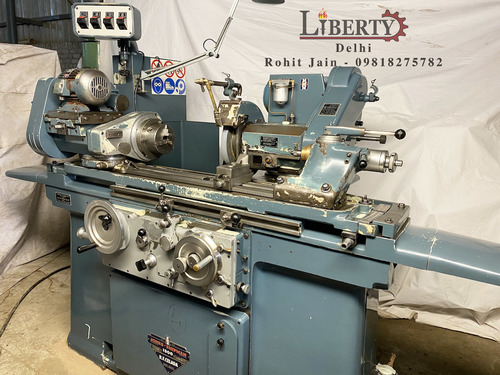

Ribon RUR-1000 Universal Cylindrical Grinding Machine

Price 100000 INR/ Piece

Ribon RUR-1000 Universal Cylindrical Grinding Machine Specification

- Product Type

- Universal Cylindrical Grinding Machine

- General Use

- Precision external and internal grinding of cylindrical components

- Material

- Heavy-duty Cast Iron and Steel

- Type

- Manual

- Capacity

- 1000 mm between centers

- Weight (kg)

- 2200 kg

- Computerized

- No

- Automatic

- No

- Control System

- Manual control handwheels

- Drive Type

- Belt Driven

- Grinding Diameter

- Up to 250 mm

- Grinding Length

- 1000 mm

- Spindle Speed

- 25 - 850 RPM (variable)

- Grinding Wheel Size

- 350 x 50 x 127 mm

- Voltage

- 415 V, 3 Phase

- Dimension (L*W*H)

- 2500 x 1450 x 1450 mm

- Feature

- Headstock with adjustable rotation, adjustable table, longitudinal and cross-travel, internal grinding attachment

- Color

- Industrial Green

- Coolant System

- Integrated with machine

- Max Workpiece Weight

- 150 kg

- Headstock Swivel

- ±90°

- Internal Grinding Attachment

- Standard

- Lubrication

- Centralized lubrication system

- Chuck Size

- 200 mm

- Tailstock Quill Travel

- 40 mm

- Surface Finish

- Up to 0.2 µm Ra

- Table Swivel

- ±8°

Ribon RUR-1000 Universal Cylindrical Grinding Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Main Domestic Market

- All India

About Ribon RUR-1000 Universal Cylindrical Grinding Machine

Make - Ribon (Italy)

Model - RUR-1000

Center Height - 140 mm

Max. Job Diameter - 280 mm

Max. Length of Job - 1000 mm

Grinding Wheel Size - Diameter 350 mm x 40 mm Width

Work-Head Speeds - 35 rpm to 310 rpm

Least Count - 2 Microns (0.002 mm)

- Equipped with Internal Grinding Attachment.

- With Micro-Feed Adjustments on Wheel-Head Movement.

- Complete with Job-Steady, Wheel Dresser, other accessories etc.

- Complete with Coolant Tank and Pump.

- Machine is in excellent working condition.

Video of The Machine -

High-Precision Grinding Performance

The Ribon RUR-1000 offers reliable and highly precise cylindrical grinding. Its manual controls provide exceptional operator flexibility, and the adjustable table and headstock cater to different angles and component sizes. Capable of achieving finely finished surfaces up to 0.2 m Ra, it is ideal for applications that demand meticulous accuracy and repeatability.

Versatile Design for Complex Tasks

Designed for both external and internal grinding, the RUR-1000 comes standard with an internal grinding attachment and adjustable machine elements. With a grinding diameter of up to 250 mm and a length of 1000 mm between centers, it is well-suited for a variety of industrial tasks, from tool manufacturing to heavy-duty part finishing.

FAQ's of Ribon RUR-1000 Universal Cylindrical Grinding Machine:

Q: How is the Ribon RUR-1000 Universal Cylindrical Grinding Machine typically used?

A: This machine is primarily used for precision grinding of external and internal cylindrical components. It is suitable for both serial and custom jobs, making it valuable in industries like automotive, tooling, and machinery manufacturing where high accuracy and a superior surface finish are critical.Q: What are the main benefits of the integrated coolant and centralized lubrication systems?

A: The integrated coolant system helps dissipate heat during grinding, preserving the workpiece's integrity in high-precision applications. The centralized lubrication system reduces wear on critical moving parts, ensuring consistent performance and extending the machine's service life.Q: When is it necessary to use the internal grinding attachment?

A: The internal grinding attachment is used when you need to grind internal surfaces, such as bores and cylindrical slots. This comes standard with the RUR-1000, enabling users to efficiently switch between external and internal grinding operations without extensive machine setup changes.Q: Where can the Ribon RUR-1000 be installed and what are its power requirements?

A: The machine has compact dimensions (2500 x 1450 x 1450 mm) and a robust build, making it suitable for industrial workshops or manufacturing floors. It requires a 415 V, 3-phase electrical supply, standard in most industrial settings.Q: What materials and components is the RUR-1000 constructed from?

A: The frame and main structural elements are made from heavy-duty cast iron and steel, providing excellent stability and vibration absorption for precise grinding results. This robust construction ensures durability and reliability even under continuous heavy-duty operation.Q: How does the manual control system benefit the operator compared to computerized alternatives?

A: Manual control handwheels provide the operator with direct tactile feedback and full control over grinding parameters, making the RUR-1000 suitable for jobs that require fine adjustments and the flexibility to handle a wide variety of components.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cylindrical Grinder Category

Jones & Shipman 1305 Universal Cylindrical Grinder

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : Other, Manual Controls

Drive Type : Other, Belt Drive

Material : Other, Cast Iron Body, Hardened Steel Components

Color : Other, Industrial Grey with Blue Trim

Ribon Rur 1000 Cylindrical Grinder

Price 6000 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : Manual

Drive Type : Belt Drive, Other

Material : Other, Metal

Color : Green

MSZ Hungary KU250/750 Universal Cylindrical Grinder

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : Other, Conventional/Manual controls

Drive Type : Other, Electric motor drive

Material : Other, Cast iron (machine body), steel (working parts)

Color : Green

Jones & Shipman 1300 Universal Cylindrical Grinder

Price 30000 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : Other, Manual Mechanical

Drive Type : Electric

Material : Other, Cast Iron, Steel Components

Color : Other, Industrial Grey / Blue

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry