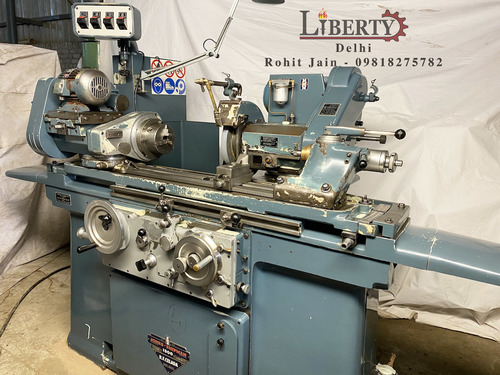

Jones & Shipman 1300 Universal Cylindrical Grinder

Price 30000 INR/ Piece

Jones & Shipman 1300 Universal Cylindrical Grinder Specification

- Product Type

- Universal Cylindrical Grinder

- General Use

- Precision External and Internal Grinding

- Material

- Cast Iron, Steel Components

- Type

- Horizontal

- Capacity

- Between Centres: 685 mm

- Weight (kg)

- Approx. 2000 kg

- Computerized

- No

- Automatic

- Semi-Automatic

- Control System

- Manual Mechanical

- Drive Type

- Electric

- Grinding Diameter

- Max. Swing over Table: 304 mm

- Grinding Length

- 685 mm

- Spindle Speed

- 20500 rpm (variable)

- Grinding Wheel Size

- 355 mm x 38 mm x 127 mm

- Voltage

- 415 V, 3 Phase

- Dimension (L*W*H)

- 2200 mm x 1700 mm x 1570 mm

- Feature

- High precision, Rigid construction, Adjustable wheelhead, Universal workhead

- Color

- Industrial Grey / Blue

- Application

- Automotive, Toolroom, Machine Building, General Engineering

- Internal Grinding Attachment

- Included (Optional on Request)

- Lubrication System

- Automatic

- Wheelhead Motor

- 2 HP

- Workhead Speeds

- Variable, up to 350 rpm

- Table Traverse

- 730 mm

- Max Weight Between Centres

- 150 kg

- Model

- 1300

- Max Distance Between Centres

- 685 mm

- Accessories

- Standard Centers, Coolant Tank, Wheel Flange, Allen Key Set

- Coolant System

- Fitted as Standard

- Chuck Size

- Up to 250 mm (With Adapter)

- Tailstock

- Provided with fine adjustment

About Jones & Shipman 1300 Universal Cylindrical Grinder

Make - Jones & Shipman (England)

Model - 1300 EIU

Center Height - 127 mm

Max. Job Diameter - 254 mm

Max. Length of Job - 686 mm

Grinding Wheel Size - Diameter 305 mm x 25.4 mm Width

Work-Head Speeds - 40 rpm to 320 rpm

Table Rotation - 20 Degree to -18 Degree

- With Internal Grinding Attachment.

- With Wheel Dresser, 2 x Steady, other accessories etc.

- With Coolant Tank & Coolant Pump.

- Machine is in excellent working condition.

Video Link -https://youtu.be/4B5YezdwtyI

Built for High Precision Applications

Engineered for accuracy and repeatability, the Jones & Shipman 1300 is suitable for both external and internal grinding of cast iron and steel components. Its universal workhead and adjustable wheelhead allow for intricate machining operations, making it an essential asset in automotive, machine building, and general engineering industries.

Sturdy Construction with Flexible Capability

With a max swing over table of 304 mm and a chuck size adaptable up to 250 mm, this grinder accommodates a wide range of workpieces. Its semi-automatic, manually controlled design offers operators direct oversight while benefiting from features like automatic lubrication and a fitted coolant system for optimal grinding conditions.

FAQs of Jones & Shipman 1300 Universal Cylindrical Grinder:

Q: How does the Jones & Shipman 1300 ensure precision during grinding operations?

A: Precision is maintained through its rigid construction, fine-adjustment tailstock, universal workhead, and automatic lubrication system. The high-quality build and mechanical control system minimize vibration and optimize accuracy for external and internal grinding tasks.Q: What materials can be ground using this universal cylindrical grinder?

A: The grinder is engineered to process cast iron, steel, and similar metallic components, making it ideal for the automotive sector, toolrooms, and general machine building applications.Q: When should the internal grinding attachment be requested?

A: The internal grinding attachment is available upon request when your operations require internal diameter machining. It is optional and can be ordered alongside or after the initial machine purchase, depending on your evolving needs.Q: Where can this grinding machine be effectively utilized?

A: This model is suitable in automotive manufacturing, toolrooms, machine building shops, and general engineering environments where high-precision external and internal cylindrical grinding is required.Q: What is the benefit of the automatic lubrication system on this machine?

A: The automatic lubrication system ensures critical moving parts are consistently oiled, reducing wear and extending the machines lifespan while supporting smooth, uninterrupted operation.Q: How does the process of adjusting workhead and tailstock settings impact performance?

A: Adjustable workhead speeds and precision-tailstock fine adjustment allow users to tailor the grinding parameters for different materials and sizes, ensuring optimal surface finish and accuracy for a variety of applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cylindrical Grinder Category

Nolaf France Universal Cylindrical Grinder Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 415V 3 Phase

Feature : Other, Precision Grinding, Sturdy Construction, Adjustable Table, High Accuracy

Grinding Wheel Size : 350 mm x 40 mm x 127 mm

Color : Other, White & Blue

Tacchella 1013-UA Precision Universal Cylindrical Grinder

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 415 V / 3 Phase / 50 Hz

Feature : Other, High precision, robust construction, universal application

Grinding Wheel Size : 350 mm x 50 mm x 127 mm

Color : Other, Machine Green with white panel

TOS BU 16 Precision Universal Cylindrical Grinder

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 380 V

Feature : Other, Precision, Sturdy Construction, Versatile Use

Grinding Wheel Size : 350 x 40 x 127 mm

Color : Other, Grey / Blue

TOS BU 16 Universal Cylindrical Grinder

Price 80000 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 415 V / 3 Phase / 50 Hz

Feature : Other, Swivelling Wheelhead, Internal Grinding Attachment, Precision Spindle

Grinding Wheel Size : 350 x 40 x 127 mm

Color : Other, Machine Gray/Green

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry