Fortuna Universal Cylindrical Grinder

Fortuna Universal Cylindrical Grinder Specification

- Product Type

- Universal Cylindrical Grinder

- General Use

- External and internal cylindrical grinding operations

- Material

- Cast iron, alloy steel, and high-grade metals

- Type

- Universal Cylindrical Grinding Machine

- Capacity

- 200 mm - 2000 mm (Grinding Length)

- Weight (kg)

- Approx. 3500 - 5500 kg

- Computerized

- No

- Automatic

- Semi-Automatic

- Control System

- Manual/PLC based

- Drive Type

- Belt Driven

- Grinding Diameter

- Up to 320 mm

- Grinding Length

- Up to 2000 mm

- Spindle Speed

- Up to 1800 rpm

- Grinding Wheel Size

- 400 mm x 50 mm x 203.2 mm

- Voltage

- 380-415 V

- Dimension (L*W*H)

- 3600 mm x 1800 mm x 1600 mm

- Feature

- High precision, sturdy construction, easy operation

- Color

- Blue & Grey

- Coolant System

- Integrated

- Workpiece Weight Capacity

- Up to 150 kg

- Application

- Tool rooms, automobile, machine parts manufacturing

- Chuck Type

- 3-jaw, 4-jaw and face plate adaptable

- Traverse Speed

- Variable

- Tailstock Type

- Movable

- Power Consumption

- 6-8 kW

- Center Height

- 160 mm

- Accuracy

- Up to 0.002 mm

- Headstock

- Swiveling, adjustable for taper grinding

About Fortuna Universal Cylindrical Grinder

Make - Fortuna (Germany)

Center Height - 185 mm

Max. Diameter of Job - 370 mm

Length of Job - 2200 mm

Grinding Wheel Diameter - 500 mm

Max. Grinding Wheel Width - 90 mm

- With Internal Grinding Attachment.

- 5 x 2-point steady, 1 x 3-point steady, 2 x dresser with machine.

- Equipped with Hydraulic Tailstock.

- Infinitely variable speed Work-Head.

- With Automatic Depth Adjustment "Auto-Cut".

- Spare grinding wheels, flanges, and lot of other accessories.

- Complete with coolant tank, pump and all covers etc.

- Machine is in as good as new condition.

- Machine is in excellent working condition.

High-Precision Grinding Capability

With an accuracy of up to 0.002 mm, the Fortuna Universal Cylindrical Grinder excels in delivering top-notch precision for demanding manufacturing environments. Its sturdy construction and variable traverse speed facilitate consistently accurate results, suitable for intricate tool room and automotive applications.

Versatile Workpiece Handling

Designed to accommodate a wide range of materials such as cast iron and alloy steel, this grinder can process workpieces ranging from 200 mm to 2000 mm in length and up to 320 mm in diameter. The combination of multiple chuck types and an adjustable headstock allows for both general and specialized grinding tasks.

Integrated Features for Operator Convenience

The integrated coolant system, manual/PLC control, and semi-automatic operation make the Fortuna grinder user-friendly and efficient. Its ergonomic design ensures easy setup and operation, while the belt-driven mechanism provides reliable performance batch after batch.

FAQs of Fortuna Universal Cylindrical Grinder:

Q: How does the Fortuna Universal Cylindrical Grinder ensure high precision during the grinding process?

A: The grinder achieves high precision, up to 0.002 mm, through its robust construction, variable traverse speed, and integrated coolant system. The manual or PLC-based controls allow fine-tuning of grinding operations, ensuring repeatable accuracy across all processed workpieces.Q: What types of workpieces and materials can be processed with this machine?

A: This grinder is suitable for grinding cast iron, alloy steel, and high-grade metals. It handles workpiece lengths from 200 mm up to 2000 mm, and diameters up to 320 mm, making it ideal for tool rooms, automobile parts, and a broad range of machine component manufacturing.Q: When is it beneficial to use the swiveling, adjustable headstock?

A: The swiveling headstock is particularly beneficial when taper grinding is required. It allows the operator to set precise angles for tapered surfaces, facilitating complex grinding operations that standard setups cannot accommodate.Q: Where is the Fortuna Universal Cylindrical Grinder typically installed and utilized?

A: The machine is commonly installed in tool rooms, automotive manufacturing facilities, and machine parts production environments. Its substantial capacity and versatility make it an excellent choice for industries requiring precision cylindrical grinding.Q: What is the process for switching between different chuck types?

A: The grinder is compatible with 3-jaw, 4-jaw, and face plate chucks. Operators can adapt the chuck setup depending on the workpiece requirements, allowing secure clamping for various shapes and sizes. This flexibility supports both standard and specialized grinding tasks.Q: How does the integrated coolant system contribute to usage and workpiece quality?

A: The integrated coolant system prevents overheating, reduces friction, and maintains optimal grinding conditions. This enhances tool life, ensures dimensional stability of the workpieces, and minimizes thermal deformation during prolonged grinding operations.Q: What are the main benefits of choosing this semi-automatic, belt-driven grinder from Germany?

A: Key benefits include high accuracy, sturdy construction, ease of operation, versatility for internal and external grinding, and reliable performance. Manufactured in Germany, it uses high-quality components and is backed by expertise in machine design, making it a preferred choice for exporters, importers, manufacturers, suppliers, and traders.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cylindrical Grinder Category

Fortuna 400 mm Length Automatic Cylindrical Grinding Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, Cast Iron, Steel

Control System : Other, PLC Controlled

Drive Type : Electric

Color : Other, Green/Grey

Fortuna Germany AFC-1000 Heavy Duty Cylindrical Grinding Machine

Price 100000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, Cast Iron, Steel Components

Control System : Other, Hydraulic & PLC based

Drive Type : Other, Electric motor driven

Color : Other, Industrial Grey

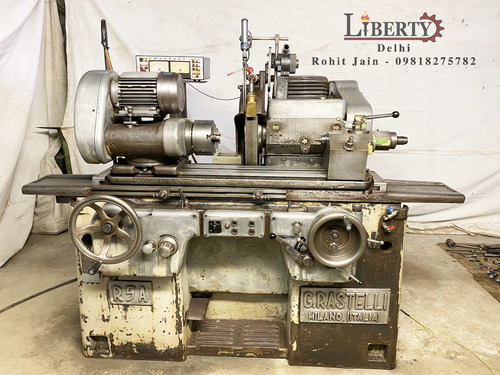

G. Rastelli R5A Cylindrical Grinder

Price 5600 INR

Minimum Order Quantity : 1 Piece

Material : Other, Cast Iron, Steel

Control System : Manual

Drive Type : Mechanical

Color : Other, Light Blue / Grey

TOS B40U/1000 Cylindrical Grinder

Price 8000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, Metal components

Control System : Manual

Drive Type : Mechanical

Color : Green

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry