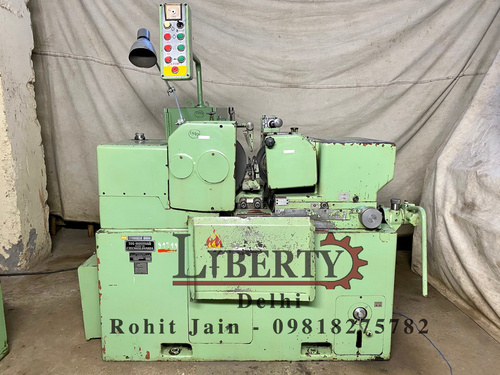

Ghiringhelli M100 Automatic Centerless Grinding Machine

Price 100000 INR/ Piece

Ghiringhelli M100 Automatic Centerless Grinding Machine Specification

- Model

- M100

- Rotation

- Clockwise spindle rotation

- Product Type

- Automatic Centerless Grinding Machine

- General Use

- Automatic centerless grinding of precision components

- Weight (kg)

- 3200 kg Kilograms (kg)

- Computerized

- No

- Automatic

- Yes

- Table Size

- 765 mm 105 mm

- Grinding Wheel Size

- 400 mm 200 mm

- Grinding Length

- 100 mm

- Floor Space

- 2600 mm 1600 mm

- Fuel Tank Capacity

- 60 Liters Liter (L)

- Voltage

- 415V / 3 Phase Volt (v)

- Dimension (L*W*H)

- 2600 mm 1600 mm 1800 mm Millimeter (mm)

- Feature

- High precision, continuous feed, auto lubrication

- Color

- Industrial Grey

- Safety Features

- Emergency stop, overload protection, safety interlocks

- Work Rest Blade

- High wear-resistant steel

- Coolant System

- Integrated with filter unit

- Drive Type

- Belt drive transmission

- Lubrication

- Automatic centralized lubrication system

- Machine Bed

- Reinforced with vibration dampening

- Hydraulic System

- High capacity hydraulic power pack

- Finish Accuracy

- Up to 0.002 mm

- Environmental Compliance

- Low noise and dust containment

- Feed Mechanism

- Automatic loading/unloading system

- Wheel Material

- Abrasive grade (Aluminium oxide/Silicon carbide)

Ghiringhelli M100 Automatic Centerless Grinding Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Delivery Time

- 5-10 Days

- Main Domestic Market

- All India

About Ghiringhelli M100 Automatic Centerless Grinding Machine

Make - Ghiringhelli (Italy)

Model - M100

Job Diameter Range - 3 mm to 85 mm

Grinding Wheel Diameter - 350 mm

Wheel Width - 100 mm

Control Wheel Diameter - 225 mm

Control Wheel Slide Swivel Angle - +5 degree to -5 degree (for Taper Jobs)

Control Wheel Feed Angle - +5 degree to -5 degree

- Feature of Fully Automatic & Semi-Automatic In-Feed Grinding Cycles.

- The Machine can work in Manual Mode as well.

- Equipped with Hydraulic Wheel Dressers.

- Control Wheel can be titled for Through-Feed Grinding.

- Control Wheel can be rotated for Taper Grinding Operations.

- Infinitely Variable Speeds of the Control Wheel.

- Machine is in excellent working condition.

Video of The Machine -

Superior Precision and Durability

The Ghiringhelli M100 is constructed with a heavy-duty alloy steel frame and features a reinforced machine bed with advanced vibration dampening. These design elements ensure consistent high-precision performance, delivering finish accuracies as fine as 0.002 mm. The grinding wheel uses premium-grade abrasives such as aluminium oxide or silicon carbide, ensuring exceptional wear resistance and longevity.

Advanced Automation and Efficiency

This centerless grinder incorporates a fully automatic loading and unloading system, coupled with a continuous feed mechanism. Operators benefit from reduced manual intervention, higher throughput, and streamlined workflow all supported by an automatic centralized lubrication system to minimize wear and boost reliability.

Integrated Safety and Environmental Controls

Safety features such as emergency stop, overload protection, and safety interlocks protect operators throughout the grinding process. Additionally, the M100 maintains low noise emissions and effective dust containment, supporting compliance with stringent workplace environmental standards.

FAQs of Ghiringhelli M100 Automatic Centerless Grinding Machine:

Q: How does the automatic loading and unloading system work on the Ghiringhelli M100?

A: The machines automatic loading and unloading system streamlines component handling by automatically transferring workpieces into and out of the grinding area, reducing manual labor and increasing production speed.Q: What materials and sizes can the M100 centerless grinding machine handle?

A: The M100 is engineered for precision grinding of components up to 100 mm in diameter, using abrasive wheels made of aluminium oxide or silicon carbide. Its robust construction accommodates a wide range of hard materials typically found in precision manufacturing.Q: When is it advantageous to use the Ghiringhelli M100 for production processes?

A: The M100 is ideal for high-volume manufacturing environments where consistent precision and minimal downtime are critical. Its automatic operation, high-capacity systems, and quick throughput make it suitable for continuous production shifts.Q: Where can the M100 be deployed within an industrial facility?

A: Designed with a compact footprint of 2600 mm 1600 mm, the M100 can be integrated into most precision machining centers, grinding lines, or component finishing areas in automotive, aerospace, or industrial machinery plants.Q: What safety mechanisms are incorporated in the M100?

A: The Ghiringhelli M100 is equipped with emergency stop controls, overload protection, and interlocked guarding systems to ensure operator safety and protect against operational hazards.Q: How does the M100 support environmental compliance?

A: With integrated dust containment and low-noise operation, the M100 helps facilities meet environmental and occupational health standards, creating a safer and more comfortable workspace.Q: What are the main benefits of using this automatic centerless grinder?

A: Operators benefit from enhanced precision, increased automation, reduced manual handling, and the ability to handle continuous high-volume grinding with minimal maintenance, leading to improved productivity and product consistency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Centreless Grinding Machine Category

Cimat Italy Centerless Grinding Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

General Use : Precision centerless grinding of cylindrical components

Product Type : Centerless Grinding Machine

Control System : Other, Siemens PLC Based

Feature : Other, High Precision, Low Vibration, Auto Lubrication

Ghiringhelli M2120 Centerless Grinder Machine

Price 21000 INR / Piece

Minimum Order Quantity : 1 Piece

General Use : Centerless grinding of cylindrical surfaces

Product Type : Centerless Grinding Machine

Control System : Other, PLC or CNC based panel

Feature : Other, Automatic size compensation, auto loading/unloading system

Ghiringhelli Italy Centerless Grinding Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

General Use : Industrial Centerless Grinding

Product Type : Centerless Grinding Machine

Control System : Manual

Feature : Other, High Precision, Robust Structure

TOS BBJ6 Centerless Grinder

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

General Use : Centerless grinding of cylindrical parts

Product Type : Centerless Grinder

Control System : Manual

Feature : Other, High precision, rigid structure

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry