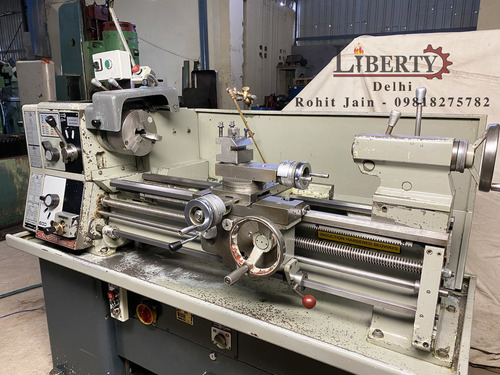

H. Ernault Somua Cholet 550 Lathe Machine

Price 100000 INR/ Piece

H. Ernault Somua Cholet 550 Lathe Machine Specification

- Product Type

- Manual Lathe Machine

- Material

- Heavy-duty Cast Iron

- Cutting Thickness

- Depends on tooling and material

- Cutting Speed

- Up to 1800 RPM

- CNC Or Not

- No

- Automatic Grade

- Manual

- Control System

- Manual

- Max. Swing Diameter

- 550 mm

- Voltage

- 415 V, 3 Phase

- Weight (kg)

- 4000 kg (Approx.)

- Dimension (L*W*H)

- Approx. 3150 x 1250 x 1450 mm

- Capacity

- Medium to Heavy-Duty Turning

- Feature

- Robust construction, accurate machining, hardened gears

- Color

- Industrial Grey

- Thread Cutting Range

- Metric: 0.25 to 16 mm, Inch: 2 to 72 TPI

- Bed Type

- Hardened and ground bed ways

- Spindle Bore

- 72 mm

- Tailstock Quill Travel

- 200 mm

- Chuck Size

- 315 mm (12 inch)

- Coolant Pump

- Yes

- Application

- Precision metalworking, industrial machining

- Spindle Speed Range

- 18 - 1800 RPM

- Tailstock Quill Diameter

- 75 mm

- Power Required

- 7.5 HP

- Lead Screw Diameter

- 40 mm

- Distance Between Centres

- 2000 mm

- Number of Spindle Speeds

- 18

H. Ernault Somua Cholet 550 Lathe Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Main Domestic Market

- All India

About H. Ernault Somua Cholet 550 Lathe Machine

Make - H. Ernault Somua (France)

Model - Cholet 550

Center Height - 250 mm

Max. Turning Length of Job - 1000 mm

Max. Distance between Centers - 1100 mm

Max. Job Diameter over Bed - 500 mm

Max. Job Diameter over Cross-Slide - 310 mm

Max. Job Diameter near Chuck - 550 mm

Bed Width - 385 mm

Spindle Bore - 52 mm

Chuck Diameter - 300 mm

Spindle Speeds - 32 rpm to 1600 rpm

- With Motorised Rapid Travels of Carriage & Cross-Slide.

- Micro-Feed Travels on the Cross-Slide Movement.

- Complete with Follow Rest, Coolant Tray & Pump.

- Machine is in excellent working condition.

Video of the Machine -

Precision and Reliability for Industrial Machining

Engineered with highly durable cast iron and hardened gears, the Cholet 550 lathe ensures accurate machining for complex metalworking tasks. Its robust construction and bed ways provide stability, minimizing vibrations during operations for reliable precision and longevity in industrial environments.

Versatile Operations and Flexible Speed Control

With a spindle speed range from 18 to 1800 RPM and 18 selectable speeds, users can adapt the machine to different material types and cutting requirements. The metric and imperial thread cutting capabilities further expand its versatility for varied machining projects.

Ergonomic Design and Manual Control System

Although equipped with advanced industrial features, this lathe remains a manual machine, granting operators hands-on control for intricate adjustments and custom machining. Its ergonomic design, including a sizeable chuck and easy-to-operate tailstock, makes it suitable for both experienced professionals and skilled technicians.

FAQ's of H. Ernault Somua Cholet 550 Lathe Machine:

Q: How do I operate the H. Ernault Somua Cholet 550 Lathe Machine for thread cutting?

A: To cut threads, utilize the lead screw and select the desired thread pitch using the lathe's control levers. The machine supports metric threads from 0.25 to 16 mm and inch threads from 2 to 72 TPI. Ensure correct tooling and setup for precise thread profiles.Q: What types of materials can this lathe machine handle in industrial environments?

A: The Cholet 550 lathe's heavy-duty cast iron structure and hardened components allow it to machine various metals-including steel, aluminum, and brass-for precision industrial applications. The cutting thickness depends on the chosen tooling and the properties of the workpiece.Q: When should I use the coolant pump during machining operations?

A: The built-in coolant pump should be used whenever high-speed cutting or lengthy operations are performed. It helps manage heat buildup, increases tool life, and ensures smooth, accurate finishes on metal components.Q: Where is the H. Ernault Somua Cholet 550 Lathe Machine typically installed?

A: This lathe machine is suitable for installation in manufacturing plants, precision metalworking workshops, and industrial machining facilities, given its medium to heavy-duty capacity and robust build.Q: What is the maximum turning capacity of the Cholet 550 lathe?

A: It can accommodate workpieces up to 2000 mm in length between centers and has a maximum swing diameter of 550 mm, making it ideal for larger components and medium-heavy tasks.Q: How does manual control on this lathe benefit machining accuracy?

A: Manual control allows operators to make real-time adjustments and monitor each machining step closely, resulting in higher accuracy, better surface finish, and flexibility for complex custom jobs.Q: What are the main benefits of hardened and ground bed ways in this machine?

A: Hardened and ground bed ways increase long-term durability and maintain consistent alignment, reducing wear over time. This ensures sustained precision and smooth movement of machining components.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Lathe Machine Category

Colchester Bantam 2000 Lathe Machine

Price 19000 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : Other, Manual/geared headstock controls

Cutting Speed : 30 to 2000 RPM

Product Type : Other, Precision Lathe Machine

Dimension (L*W*H) : 1600 mm x 900 mm x 1100 mm (approx)

TOS SU63A / 2750 Heavy Duty Lathe Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : Other, Manual

Cutting Speed : 18900 RPM (12 steps)

Product Type : Other, Heavy Duty Lathe Machine

Dimension (L*W*H) : 4650 x 1570 x 1660 mm

Colchester England 2000 mm Length Gap-Bed Lathe Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : Other, Geared manual controls

Cutting Speed : Manual control, up to 2000 mm length capacity

Product Type : Other, GapBed Lathe Machine

Dimension (L*W*H) : Approx. 3200 mm x 850 mm x 1400 mm

Femaru Hungary Heavy Duty Lathe Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : Other, Manual

Cutting Speed : 30 1200 RPM

Product Type : Other, Heavy Duty Lathe Machine

Dimension (L*W*H) : 3200 x 1100 x 1450 mm

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry